English

T: +86-0731-85185770

E: enquiry@qilumetal.com

E: enquiry@qilumetal.com

No. 18 Xiangfu Middle Road,Yuhua District, Changsha City

Views: 0 Author: Site Editor Publish Time: 2025-08-09 Origin: Site

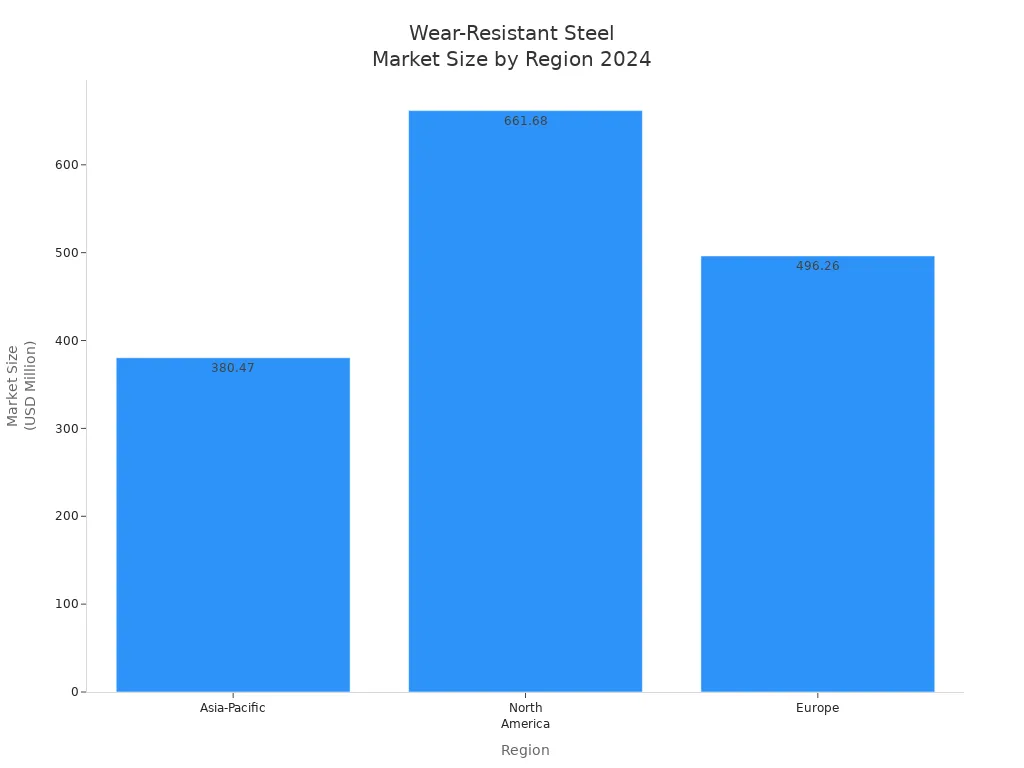

Wear-resistant steel helps machines last longer in hard jobs. These jobs include mining and construction. This steel is special because it has more chromium and manganese. It also has other alloys. These things make it harder and stronger than normal steel. Engineers pick wear-resistant steel for its tough surface. It can take heavy hits without breaking. The world market for this steel was over $3.9 billion in 2024. Asia-Pacific sold the most by volume.

| Region | Market Size 2024 (USD Million) | Market Share (%) |

|---|---|---|

| Asia-Pacific | 380.47 | ~23% |

| North America | 661.68 | >40% |

| Europe | 496.26 | >30% |

Wear-resistant steel is much stronger than regular steel. It is also harder. This steel has chromium and manganese in it. These metals make it good for hard jobs like mining. It is also used in construction.

This steel lasts a long time. Machines need fewer repairs when using it. There is less downtime for machines. This saves money for companies. It also helps the environment by making less waste.

There are different grades of wear-resistant steel. Each grade works best for certain jobs. AR400 is easier to shape. AR500 is very tough and handles heavy impacts well.

Picking the right steel grade is important. Using proper heat treatment helps machines last longer. It also makes machines work better. Always think about the job and the environment before choosing.

Wear-resistant steel can make machines lighter. Lighter machines use less fuel. This helps companies save money on fuel. It also helps them work faster and better.

Wear-resistant steel is made for hard jobs. It works well where things rub or hit a lot. Makers add chromium and manganese to make it tough. This makes it stronger than regular steel. Abrasion resistant steel does not get damaged easily. It can handle rough use and strong hits. This helps machines last longer and work better.

Abrasion resistant steel comes in different shapes. Some are plates and some are castings. These protect machines from wearing out fast. Engineers pick wear-resistant steel for tough jobs. It can take many hits and harsh weather. Its special structure stops cracks and buildup. This saves time and money.

Industries use wear-resistant steel to keep machines working. Mining and construction need abrasion resistant steel for many parts. Mining uses it for bucket liners and crusher jaws. Construction needs it for bulldozers and excavators. Trucks and trailers also use it because it lasts long.

The table below shows how industries use abrasion resistant steel:

| Industry | Primary Applications |

|---|---|

| Construction and Mining | Wear liners, rock breakers, bulldozers, excavator bucket liners |

| Transportation and Automotive | Bulldozers, lorries, trailers, dump trucks |

| Agriculture and Farming | Harvester blades, chutes, soil tilling equipment, plowshares |

| Energy and Power Generation | Boiler blades, turbines, hoppers |

| Steel and Cement | Liners, buckets, hoppers, chutes |

Companies pick wear-resistant steel for many reasons:

It helps machines last longer and need less fixing.

Abrasion resistant steel keeps machines running by fighting wear.

It is hard and tough, so it works in rough places.

The steel stops early damage and flow problems.

Mining and construction need abrasion resistant steel for safety and long life. This steel is a smart choice for heavy jobs.

Wear-resistant steel is special because it is very hard and tough. These two things help it work well in rough places. Other steels might break or wear out, but this steel does not. Hardness means the steel does not scratch or wear down easily. Toughness means it can take hits without breaking. Both are needed for machines that get hit a lot or rub together.

The way the steel is made gives it these good traits. Makers heat the steel and then cool it fast. This is called quenching. It makes the steel’s inside very hard. After that, they temper the steel. Tempering helps the steel stay tough and not get too brittle.

Alloying elements are important in making this steel. Carbon makes the steel harder and stronger. Manganese helps the steel be tough and harden all over. Chromium makes the steel harder and helps it fight wear. These elements work together to make abrasion resistant steel last longer and work better than normal steel.

Note: The right mix of carbon, manganese, and chromium helps make strong steel that does not break during hard jobs.

Here is a table that shows the main mechanical properties of abrasion resistant steel:

| Property | Typical Range (Metric) | Description |

|---|---|---|

| Tensile Strength | 600 - 700 MPa | Resistance to breaking under tension |

| Yield Strength | 350 - 450 MPa | Stress where permanent shape change starts |

| Elongation | 15 - 20% | Ability to stretch before breaking |

| Hardness (Brinell) | 170 - 210 HB | Resistance to wear and abrasion |

| Impact Strength | 30 - 50 J | Energy absorbed before fracturing |

Normal steels like A36 are not as hard or strong. For example, A36 steel is softer and has lower yield strength. Abrasion resistant steel can last up to four times longer. It is both hard and tough, so it does not crack easily. This makes it great for mining, construction, and other hard jobs.

Abrasion resistant steel is made to stop wear from rubbing or hitting. Its high abrasion resistance comes from what it is made of and how it is made. High carbon alloy steel has manganese and chromium. These make hard carbides that protect the steel’s surface. The carbides act like armor and stop sharp things from wearing down the steel.

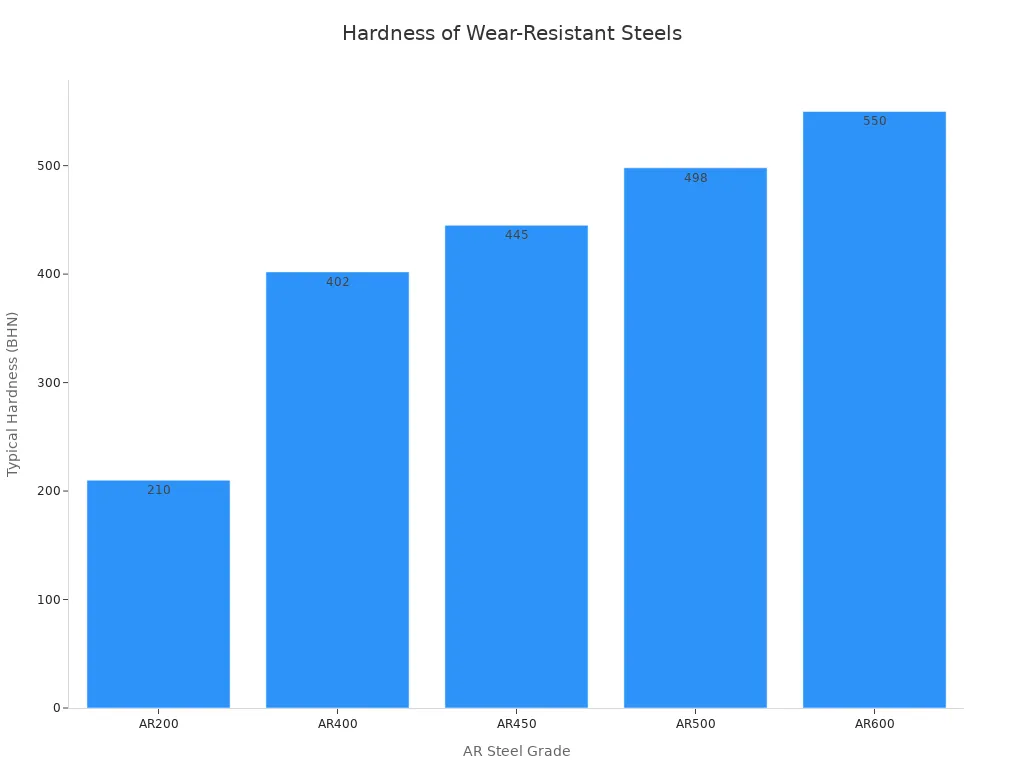

The table below compares the hardness and abrasion resistance of different grades of abrasion resistant steel:

| AR Steel Grade | Typical Hardness Range (BHN) | Abrasion Resistance Characteristics |

|---|---|---|

| AR200 | 170 - 250 | Moderate hardness, basic abrasion resistance |

| AR400 | 360 - 444 | Improved resistance, good formability |

| AR450 | 420 - 470 | Balanced abrasion and impact resistance |

| AR500 | 470 - 525 | Very high abrasion resistance, less formable |

| AR600 | Above 525 | Highest resistance, can be prone to cracking |

Grades like AR400 and AR500 are much harder than mild steel. This means they can handle rough use and heavy loads. They do not wear out fast. The high abrasion resistance helps machines and parts last longer. This means less fixing and fewer new parts.

Alloying elements also help a lot. Here is a summary of what each element does:

| Alloying Element | Contribution to Abrasion Resistance |

|---|---|

| Carbon | Forms hard carbides, increases hardness and strength |

| Manganese | Improves toughness, hardenability, and wear resistance |

| Chromium | Boosts hardness, wear resistance, and corrosion resistance |

Manganese forms carbides and mixes into the steel’s inside. In high-manganese steels, the surface gets harder as it is used. This is called work hardening. It makes abrasion resistant steel even stronger in tough jobs.

Tip: Pick the right grade of abrasion resistant steel for the job. AR500 or AR600 are good for heavy impacts. AR400 is better if you need to bend or weld the steel.

New technology has made even better abrasion resistant steel. Nanostructured steels and high-strength alloys last longer and work better. These new steels help industries do harder jobs and keep machines working longer.

Wear resistant steels help machines last much longer. Many industries use abrasion resistant steel for hard jobs. These steels have carbon, manganese, and chromium. This mix makes them strong and protects against wear. Using better grades of abrasion resistant steel helps a lot. For example, changing from 400 HBW AR steel to Hardox 600 can make machines last four times longer. Some mining tools last 50% longer with Hardox 600 than with 500 HBW AR steel. SSAB, a top steel maker, saw these results in real mines.

Using Hardox 600 instead of 500 HBW AR steel can make equipment last 50% longer.

Using Hardox 600 instead of 400 HBW AR steel can make service life four times longer.

These results come from real mining tests.

Abrasion resistant steel plates mean fewer part changes. In a Swedish iron ore plant, ROXDUR liners lasted over 4,000,000 tons. The old plates only lasted 500,000 tons. This means less downtime and fewer part changes.

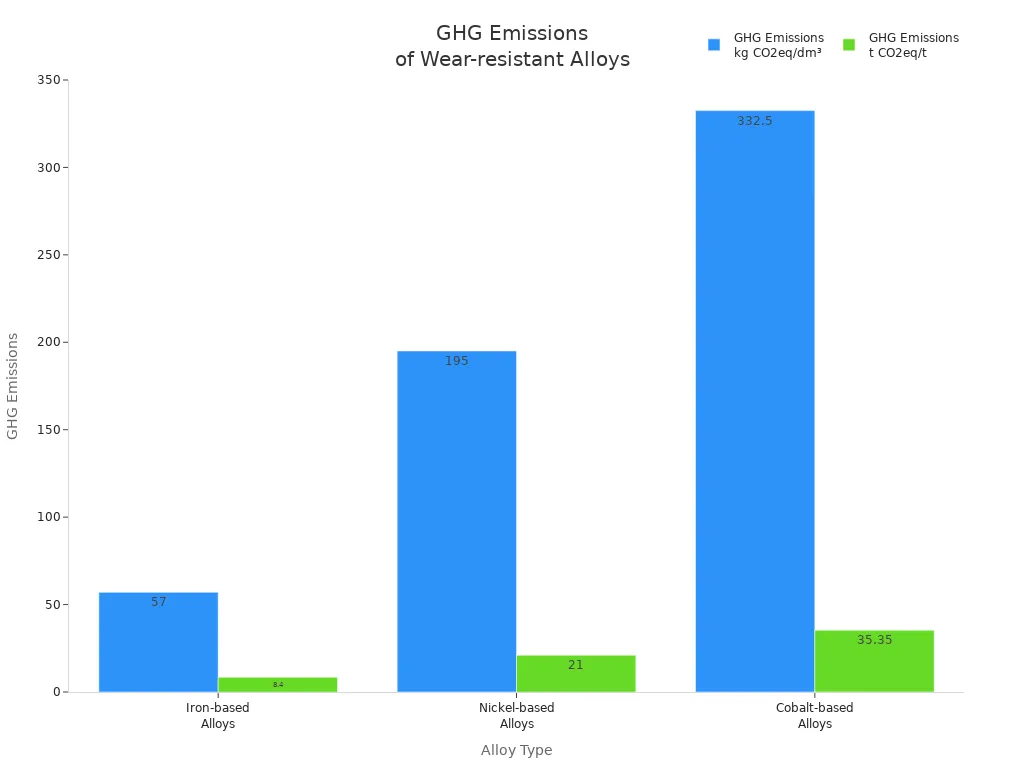

Wear resistant steels also help the planet. They last longer, so there is less waste. Iron aluminide-based wear resistant steels make less greenhouse gas than cobalt or nickel-based alloys. These steels can save up to 50 tons of CO2 each year for some parts.

| Aspect | Iron-based Alloys (Iron Aluminides) | Nickel-based Alloys | Cobalt-based Alloys |

|---|---|---|---|

| Production GHG Emissions (kg CO2eq/dm³) | ~57 | 185–205 | 318–347 |

| Production GHG Emissions (t CO2eq/t) | ~8.4 | 20–22 | 31.2–39.5 |

| Environmental Impact Reduction vs. Cobalt Alloys | Up to 75% lower impact | N/A | Baseline |

| Wear Resistance at High Temperatures | Superior, up to 700 °C | High | High |

| Lifetime Effect on Environmental Impact | Longer lifetime reduces replacement needs, saving up to 50 t CO2eq/year | Shorter lifetime increases impact | Shorter lifetime increases impact |

| Resource Savings by Doubling Service Life | Up to 8.8 Gt resources/year saved globally | N/A | N/A |

Wear resistant steels help companies save money and protect the planet by lasting longer and making less waste.

Abrasion resistant steel lowers repair needs and costs for machines. These steels are very hard and strong, so parts do not wear out fast. This means fewer fixes and less time when machines stop.

Wear resistant steel plates last longer and stop wear problems.

Fewer repairs and part changes save money.

Real cases show longer life and cost savings after switching to abrasion resistant steel.

In a copper mine in Peru, ROXDUR liners replaced white iron plates that lasted only one month. The new liners lasted much longer and saved money.

A steel mill used CHROMEWELD 600 plates and got two years of use instead of just a few months, so they had fewer shutdowns and lower costs.

Companies can plan repairs instead of waiting for things to break. This saves money and keeps machines working. Even though wear resistant steels cost more at first, they save money over time because there are fewer repairs and part changes.

Wear resistant steels also help make machines lighter. HARDOX 500 plates are strong and let makers use thinner, lighter parts. Lighter machines can carry more and use less fuel. Dump trucks and excavators can move more stuff with less fuel. This means fewer trips and lower fuel costs.

Lighter machines can carry more and use less fuel.

Fewer trips mean less fuel used.

Needing less repair time helps machines work more.

Longer part life means less downtime and better work.

Saving money comes from using less fuel and fixing less.

Wear resistant steels help the planet in factories too. They last longer, so there is less waste and less energy used. Makers use energy-saving ways and recyclable stuff to make these steels. This helps companies meet green goals and work better.

Companies that use abrasion resistant steel spend less, have less downtime, and work better.

Many industries pick different abrasion resistant steel grades for their jobs. Each grade has its own hardness and toughness. Here are some common grades:

AR200: This is a cheaper grade. It gives medium abrasion resistance. It works for jobs with light wear.

AR400: This grade is hard but still easy to shape or weld. It is used a lot in mining and construction.

AR450: This grade is harder than AR400. It is good for very rough jobs.

AR500: This grade is very hard. It is best for high-impact or ballistic uses.

AR600: This grade is the hardest. It is used where things wear out fast, but it can break more easily.

The table below shows how AR400 and AR500 compare:

| Property | AR400 Steel | AR500 Steel |

|---|---|---|

| Hardness | About 400 Brinell (HB) | About 500 Brinell (HB) |

| Toughness | More tough and bends better | Less tough; breaks easier |

| Wear Resistance | Good for heavy wear | Very high; best for extreme wear |

| Machinability | Easier to cut and shape | Harder to cut and shape |

| Weldability | Good if you are careful | Needs careful heat control |

| Applications | Mining, dump trucks, crushers | Armor plates, shooting targets |

AR400 is a good choice if you want both strength and easy work. AR500 is better for very tough jobs but is harder to shape.

Abrasion resistant steel can be alloy steel or carbon steel. Alloy steel has extra things like chromium, molybdenum, or vanadium. These make hard carbides that help stop wear and make the steel stronger. Carbon steel uses mostly carbon to get hard. It cannot make hard carbides, so it does not fight wear as well.

Alloy steel does not rust as fast and works in tough places.

Carbon steel breaks easier and rusts faster.

Alloy steel lasts longer but costs more and is harder to cut or weld.

Carbon steel is cheaper and easier to use but does not last as long in hard jobs.

Many industries use abrasion resistant steel for many jobs. The table below shows where each grade is used:

| Steel Grade(s) | Typical Industries | Common Applications |

|---|---|---|

| AR400, Hardox 400 | Mining, Construction, Machinery | Buckets, mine cars, conveyor belts, crushers |

| AR450, Hardox 450 | Mining, Agriculture, Ore Processing | Excavators, shovels, mining trucks, hoppers |

| AR500, Hardox 500 | Military, Heavy Machinery | Armor plates, high-wear parts |

| 4140 Steel | Automotive, Aerospace | High-load, wear-resistant mechanical parts |

These grades help companies pick the right steel for their needs. Many machines need the right grade to last longer and stay safe.

Picking wear-resistant steel for factories needs careful thought. Engineers check what the job needs and what kind of wear will happen. They also look at where the steel will be used. The steel’s chemical makeup is important, especially how much carbon it has. More carbon makes steel harder and better at fighting wear. But too much carbon can make steel break easier. Medium-carbon steels are tough and fight wear, so they work well for gears and axles. Low-carbon steels bend and weld easily but do not fight wear as well.

Heat treatment helps steel work better. Quenching and tempering make the steel hard and strong by changing its inside. Surface hardening, like carburizing and nitriding, puts a tough layer on the outside. This helps the steel fight wear but keeps the inside tough. Induction hardening makes only some parts harder, so the rest stays the same.

Engineers pick steel grades based on the type of wear. Martensitic alloys are good for both rubbing and hitting. Carbide alloys fight rubbing but can lose toughness. Austenitic alloys are good for hits and get harder with use, but do not fight rubbing as well. Tool steel is picked for cutting tools because it is very hard and fights wear.

Tip: Always check if the steel is certified and if the supplier is trusted. This helps stop problems and keeps the quality the same.

The table below shows what to think about when picking wear-resistant steel:

| Factor Category | Key Considerations and Effects |

|---|---|

| Chemical Composition | Carbon makes steel harder; chromium forms hard carbides; manganese helps steel get harder with use; molybdenum and vanadium help steel fight wear. |

| Microstructure | Small grains and martensite make steel fight rubbing better; defects make steel wear out faster. |

| Processing | Heat and working the steel make its inside better and stronger. |

| Environmental Factors | High heat and harsh places can make steel wear out faster. |

| Improvement Methods | Hardening the surface and adding hard layers help tools last longer and fight wear. |

Engineers should not use regular building steel for wear jobs. They should not pick steel just because it is cheap. They need to think about what causes wear, how strong the steel is, and what the job needs. Working with suppliers and machine makers helps pick steel that lasts longer and works better for less money.

Wear resistant steels help machines last longer and work better. They also lower repair costs in tough jobs. How well they work depends on hardness and other things. Friction, lubrication, and the environment also matter. Picking the right grade gives the best results for each use. Top suppliers test their steels and give good advice. They help users choose the right steel for their needs. Companies should talk to skilled engineers or trusted suppliers. These experts know the special problems of each project and can help.

Wear-resistant steel has more chromium and manganese. These make it harder and tougher. Regular steel does not protect as well from wear.

Mining, construction, and farming use this steel a lot. Companies use it for buckets, liners, and blades. These parts get worn out fast and need to be strong.

You can weld or cut wear-resistant steel, but you must be careful. The right tools and steps help stop cracks. Preheating and cooling slowly work best.

Wear-resistant steel lasts longer than regular steel. This means fewer repairs and part changes. Machines work more and stop less. Companies spend less on fixing things over time.