English

T: +86-0731-85185770

E: enquiry@qilumetal.com

E: enquiry@qilumetal.com

No. 18 Xiangfu Middle Road,Yuhua District, Changsha City

Views: 0 Author: Site Editor Publish Time: 2025-08-08 Origin: Site

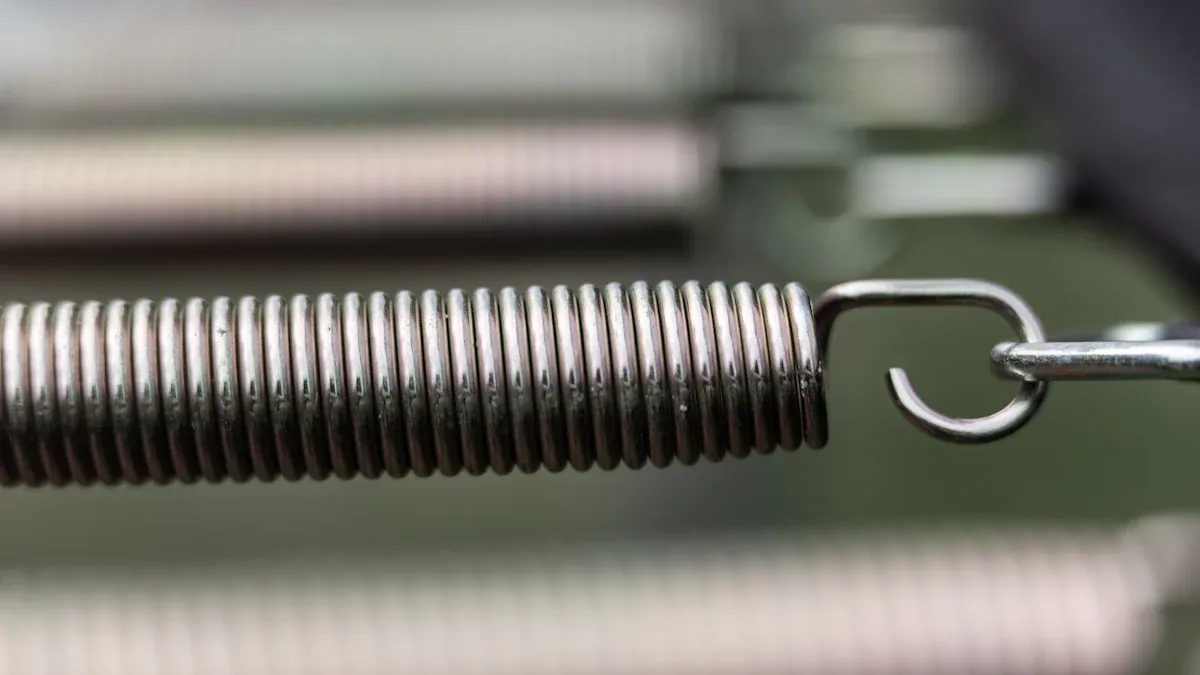

Spring steel is a type of high-carbon steel. A steel supplier often suggests it for springs and spring materials.

Spring steel has high yield strength. It also has great elasticity. It can resist fatigue very well.

These features help springs go back to their shape after bending or twisting.

Many industries use spring steel. It is used in car parts, tools, and industrial machines.

Spring steel is special because it is very strong and flexible. It can bend or twist and go back to its shape. It does not get damaged easily. Its great hardness and ability to resist wearing out make it last a long time. Spring steel works well for things used over and over, like car parts and machines. There are different types of carbon spring steel. They have a good mix of strength and flexibility. This makes spring steel a smart choice for many tools, car parts, and things people use every day.

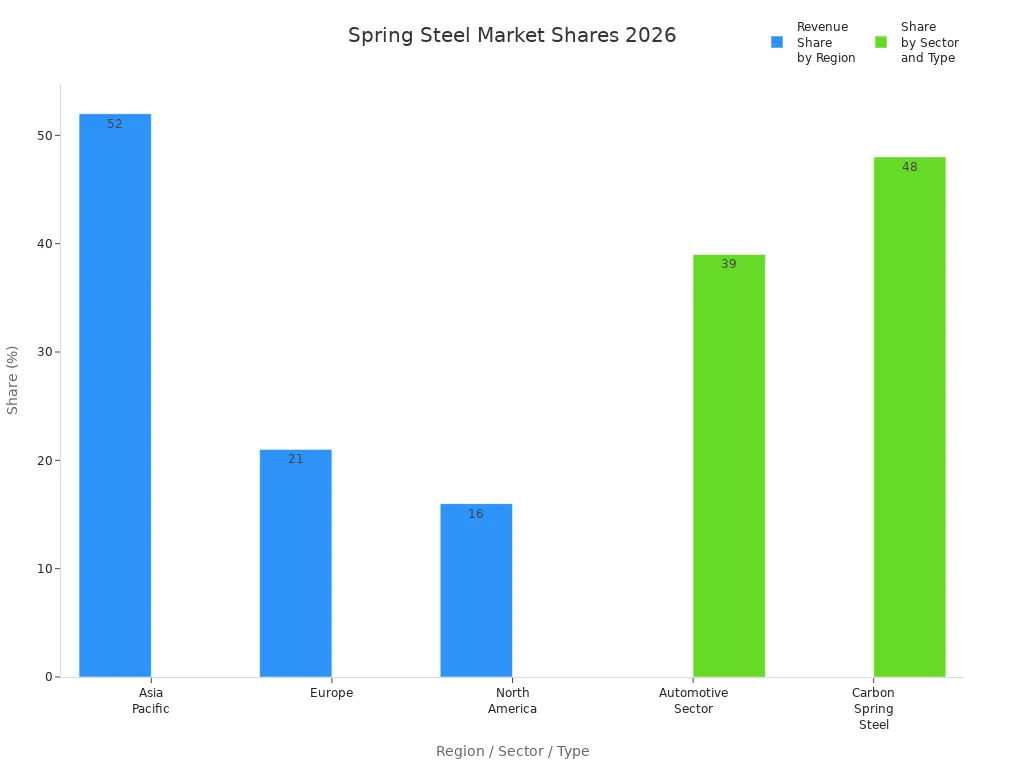

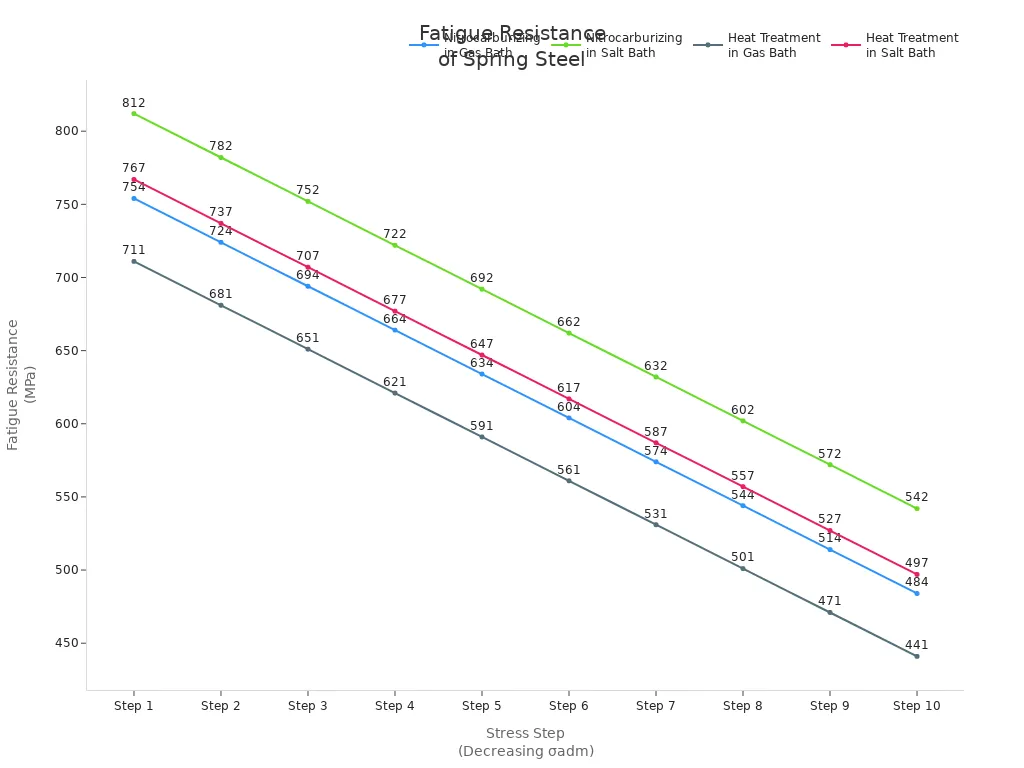

Yield strength is a very important property of spring steel. It tells us how much stress the material can take before it bends for good. Spring steel has much higher yield strength than mild or medium carbon steels. The table below shows how different steel types compare:

| Steel Type | Typical Yield Strength Range (MPa) | Notes on Application or Composition |

|---|---|---|

| Mild Steel | 200 - 350 | Low carbon steel, relatively low strength |

| Medium Carbon Steel | 350 - 450 | Moderate strength, common structural steel |

| High Carbon Steel | 600 - 700 | Used in springs, cutting tools, high-strength wire |

| Tool Steel | 500 - 2200 | Alloyed and heat treated, high strength |

| Maraging Steel | 1400 - 2400 | Very high strength, specialized alloys |

Spring steel usually has yield strength from 600 MPa to over 2000 MPa. This depends on wire size and heat treatment. Because of this, spring steel can handle heavy loads without bending for good. Things like car suspension springs and machine parts use spring steel for this reason. These parts need to keep their shape and work well even after many uses. High yield strength also helps keep things safe and reliable. It stops parts from breaking and helps them last longer.

Spring steel’s yield strength is not just high, but also steady. This makes it a top pick for elastic parts that must go back to their shape after bending or twisting.

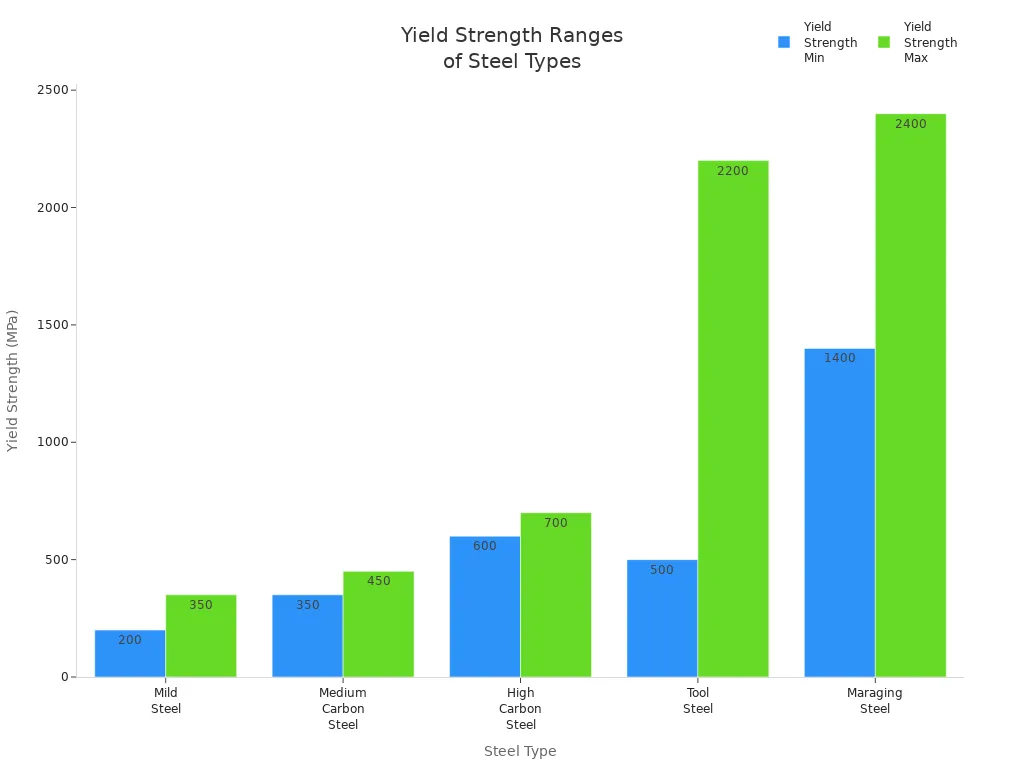

Elasticity means how well a material can stretch or bend and then return to its shape. Spring steel has high elasticity. This is important for parts that get loaded and unloaded many times. The Young’s modulus of spring steel is about 200-207 GPa. This number is much higher than aluminum or titanium. It shows that spring steel is stiffer and better for jobs that need exact movement.

| Material | Young's Modulus (GPa) |

|---|---|

| Spring Steel | ~200-207 |

| Polystyrene | 3 |

| Aluminium Alloy | 69-70 |

| Titanium | 120 |

| Copper | 130 |

| Tungsten Carbide | 600 |

| Diamond | 1200 |

Spring steel’s high elasticity lets it bend under stress and then go back to its shape when the stress is gone. This is very important for springs, clips, and other elastic parts. These parts must work well for many cycles. The mix of high elasticity and yield strength makes spring steel special. It can take in and give back energy very well.

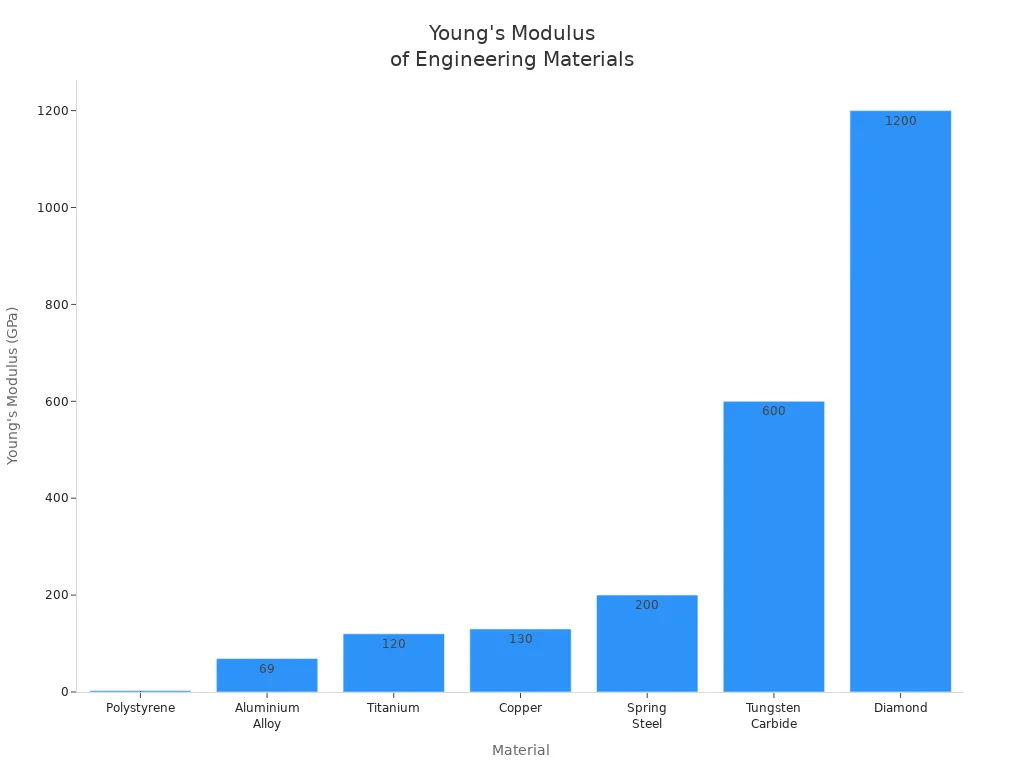

Fatigue resistance is another key property of spring steel. It shows how well the material can handle being loaded and unloaded many times without cracking or breaking. Spring steel has great fatigue resistance. This means it can last through millions of cycles in tough places.

| Treatment Type | Typical Fatigue Resistance Values (Stress Amplitudes in MPa) |

|---|---|

| Nitrocarburizing in Gas Bath | 754, 724, 694, 664, 634, 604, 574, 544, 514, 484 |

| Nitrocarburizing in Salt Bath | 812, 782, 752, 722, 692, 662, 632, 602, 572, 542 |

| Heat Treatment in Gas Bath | 711, 681, 651, 621, 591, 561, 531, 501, 471, 441 |

| Heat Treatment in Salt Bath | 767, 737, 707, 677, 647, 617, 587, 557, 527, 497 |

Many things help spring steel have high fatigue resistance:

High yield and tensile strength let it take bigger loads without bending for good.

More hardness helps it resist wear when loaded again and again.

Good heat treatment and surface finishing make its properties and life better.

Pure material and new processing methods, like laser shock peening, make fatigue resistance even better.

Spring steel’s fatigue resistance makes it great for car suspension systems, machines, and other uses. These parts need to handle lots of movement and stress.

Hardness tells us how well a material can resist scratching, dents, and wear. Spring steel gets high hardness from its chemical makeup and heat treatment. More carbon and elements like chromium and vanadium make it harder and help it resist wear. For example, cryogenic treatment of 51CrV4 spring steel makes its structure better. This leads to less wear and better durability.

The hardness of spring steel is very important for its use in parts that wear out, like car parts, cutting tools, and farm machines.

Hardness also helps with other properties, like fatigue resistance and yield strength. By staying hard, spring steel can resist damage on the surface and keep its properties for a long time, even in tough places.

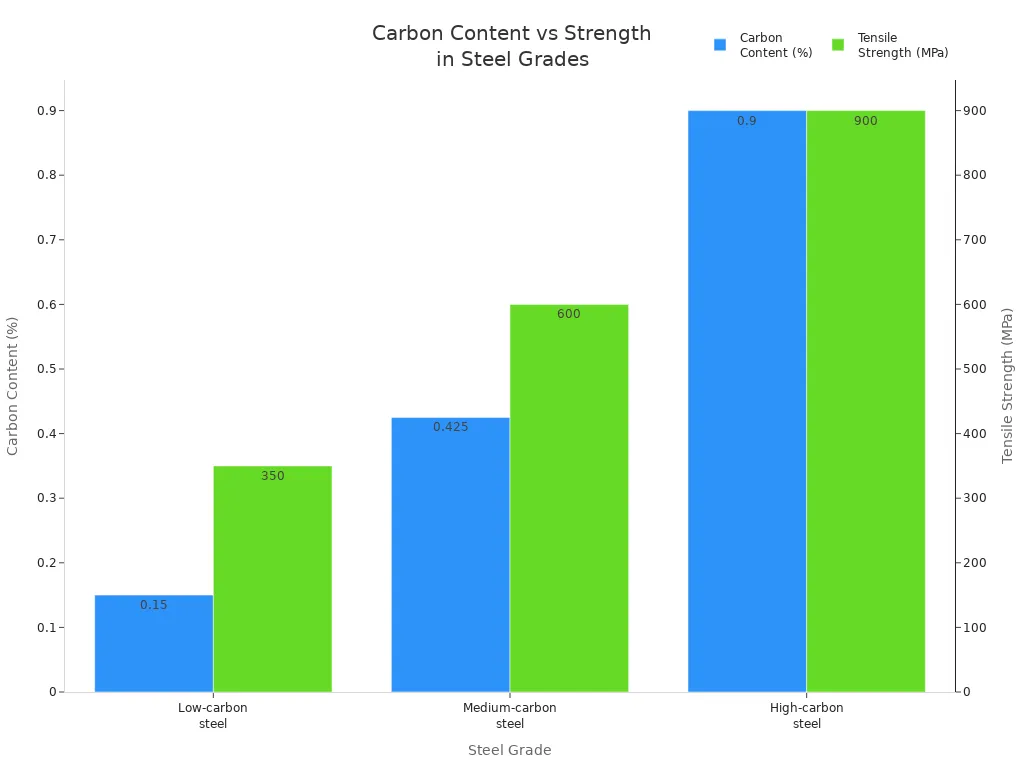

Carbon spring steel has more carbon than most other steels. The carbon amount is usually between 0.6% and 1.0%. This makes the steel strong and hard. When there is more carbon, the steel gets even harder and stronger. But it also becomes less bendy and can break more easily. Heat treatment helps balance these things. It makes the steel tough enough for springs but not too easy to break.

High-carbon steel can get very hard and strong after heat treatment. This is why it works well for springs, blades, and wires that must hold heavy loads and bend many times.

The table below shows how carbon changes steel’s properties and uses:

| Steel Grade | Carbon Content (%) | Mechanical Properties | Typical Applications |

|---|---|---|---|

| Low-carbon steel | ~0.05–0.25 | Low to medium strength, high ductility | Structural fabrication, welding |

| Medium-carbon steel | ~0.25–0.60 | Medium strength, moderate ductility | Gears, axles, shafts, forged parts |

| High-carbon steel | ~0.60–1.20+ | High strength and hardness, low ductility | Springs, blades, cutting tools |

Engineers use a few main carbon spring steel grades. Each grade is good for different jobs. The most used grades are SAE 1065, 1070, 1075, 1080, 1090, and 1095. Each one has a little more or less carbon and different strengths.

SAE 1065 and 1070: These are strong and used for small springs and clips.

SAE 1075 and 1080: These are even stronger and harder. They are good for bigger springs and parts that take more force.

SAE 1090 and 1095: These have the most carbon. They are the hardest and strongest after heat treatment. They are used for heavy springs, cutting tools, and strong wires.

SAE 1070-1090 grades are known for being strong and lasting a long time. Makers often oil-temper these steels. This gives them a special structure that makes them even stronger. These grades do not cost a lot and are easy to find. But they can rust, so they often get an oil dip or a special coating.

Spring steel grades like SAE 1070-1090 are used in car springs, machines, and tools. They are strong and can handle lots of use, so people trust them for hard jobs.

Spring steel grades are not the same everywhere. Europe and Japan have their own grades. The names are different, but the steel is similar. Engineers use charts to match grades for projects in different countries.

Carbon spring steel uses more than just carbon to get its special features. Other elements help make the steel strong, tough, and stretchy.

| Alloying Element | Role in Carbon Spring Steel Performance |

|---|---|

| Carbon (0.5-1.0%) | Increases hardness and strength, critical for high yield strength and fatigue resistance |

| Manganese (0.5-1.0%) | Improves hardenability and toughness, enhances wear resistance |

| Silicon (0.2-0.5%) | Enhances strength and elastic properties; acts as a deoxidizer to improve steel quality |

| Chromium (0.5-1.0%) | Contributes to corrosion resistance and overall durability |

Carbon: Makes the steel stronger and harder, but less bendy.

Manganese: Makes the steel tougher and easier to heat treat.

Silicon: Helps the steel stay strong and stretchy, so springs snap back.

Chromium: Helps the steel resist rust and last longer, especially in spring steel alloys.

All these elements work together to give carbon spring steel its special mix of strength, stretchiness, and toughness. Heat treatment is very important to get the best from these elements. By changing how much of each element is used and using the right heat treatment, makers can create spring steel for many jobs.

Spring steel with the right mix of elements and good heat treatment can handle lots of bending and last a long time, even in tough places.

Spring steel is very important in making cars. Engineers use it for suspension systems and clutch springs. It is also used in other car parts. These springs must hold heavy weight and bend without breaking. They need to go back to their shape after bending. Cars use coil springs, leaf springs, compression springs, and torsion springs. These are all made from spring steel. People pick spring steel because it is strong and does not wear out fast. It can handle stress again and again.

A supplier will often say to use spring steel for car parts. This is because it lasts a long time and keeps cars safe.

The table below shows how spring steel fits different car parts:

| Application Type | Performance Requirements |

|---|---|

| Suspension Springs (coil, leaf, torsion) | High tensile strength, excellent fatigue resistance, ability to flex and compress repeatedly without permanent deformation |

| Clutch Springs | High yield strength, fatigue resistance, ability to maintain mechanical properties under cyclic loading |

| General Automotive Springs | Corrosion resistance, clean surface finish, low non-metallic inclusions for fatigue-loaded springs |

Car makers use sheets and wires to make springs that last for years. The need for spring steel in cars is growing. Big companies make millions of tons every year.

Spring steel is used in many machines and tools. It is found in springs for machines, clips, fasteners, and medical tools. These springs must bend, twist, and squeeze many times. Spring steel is strong and bounces back to its shape. It is also used for piano wire, lockpicks, landing gear, and shims.

Factories use spring steel for:

Compression springs in big machines

Torsion springs for spinning parts

Leaf springs to absorb shocks

Spring steel lasts longer and costs less than some other metals. The 6150 alloy is strong, tough, and does not rust easily. This makes it good for springs in machines.

Many tools and things we use every day have spring steel. Scissors, clips, keychains, and measuring tapes use springs made from it. Farm tools like tiller blades and plow edges also use spring steel because it is tough.

| Application Area | Examples of Tools and Consumer Products | Advantages of Spring Steel in These Contexts |

|---|---|---|

| Tools and Blades | Cutting tools, saw blades, hand tools | Hardness, wear resistance |

| Agriculture and Farming | Plow blades, harrow discs, agricultural machinery parts | Strength, durability |

| Consumer Goods | Measuring tapes, lock mechanisms, musical instruments | Flexibility, resilience |

Spring steel helps these products last longer and work better. Springs can be made in many shapes and sizes. This makes spring steel a great choice for both machines and things we use every day.

Spring steel is known for being strong and lasting a long time. Many companies use it for parts that need to bend or hold weight. It is also good for things that must stretch without breaking.

| Key Benefit | Explanation |

|---|---|

| High Tensile Strength | It can hold heavy weight and does not lose its shape. |

| Excellent Elasticity | It can take in and give back energy without changing. |

| Durability | It works well even when used again and again. |

| Wear Resistance | It does not break easily, even after many uses. |

| Cost-Effectiveness | It is not too expensive and works well for big projects. |

Engineers pick spring steel because it works for many things, like cars and tools. Its special features make it a good pick for hard jobs.

Spring steel has higher yield strength and elasticity. It returns to its original shape after bending. This makes it ideal for springs and flexible parts.

Yes. Spring steel can rust if left unprotected. Many manufacturers add coatings or oil to help prevent corrosion.

People use spring steel in car suspension systems, industrial machines, and hand tools. It works well in parts that need to bend and return to shape.