English

T: +86-0731-85185770

E: enquiry@qilumetal.com

E: enquiry@qilumetal.com

No. 18 Xiangfu Middle Road,Yuhua District, Changsha City

Views: 0 Author: Site Editor Publish Time: 2025-08-07 Origin: Site

Choosing between 304 stainless steel and 316 stainless steel depends on where you use it. Many kitchens, food factories, and car parts use 304 stainless steel. It is strong against rust, easy to clean, and lasts a long time. If a project deals with strong chemicals or lots of rust, 316 stainless steel is better. It fights rust even more. Chemical plants, boats, and medicine machines often need 316 stainless steel. It works well for a long time. You should pick the one that matches how much rust and chemical damage it can handle. Price and how long it lasts are also important.

The table below shows where each type is used most:

| Stainless Steel Grade | Common Project Environments |

|---|---|

| 304 | Kitchen equipment, brewing tanks, dairy processing, automotive components, architectural structures |

| 316 | Marine fittings, chemical processing, pharmaceutical equipment, offshore platforms |

When you look at 304 and 316, the big difference is what they are made of and how they fight rust. 304 stainless steel has more chromium and less nickel than 316. It does not have molybdenum. 316 stainless steel has molybdenum. This helps it stop rust better, especially with salt or chemicals.

304 stainless steel is good for kitchens, food factories, and buildings. It can handle rust in most places inside and outside.

316 stainless steel is better against rust from saltwater and chemicals. People use it for boats, chemical plants, and medicine machines.

316 stainless steel costs more because of what it is made of, but it lasts longer in hard places.

304 stainless steel can bend more, but 316 stainless steel is stronger and harder.

Note: You should pick the one that fits where you use it, how much rust you expect, and your budget.

The table below shows what makes up 304 stainless steel and 316 stainless steel:

| Element | 304 Stainless Steel (%) | 316 Stainless Steel (%) |

|---|---|---|

| Chromium | 17.5 - 19.5 | 16.0 - 18.0 |

| Nickel | 8.0 - 10.5 | 10.0 - 14.0 |

| Molybdenum | 0 | 2.0 - 3.0 |

316 stainless steel has molybdenum. This helps it fight rust from salt and chemicals.

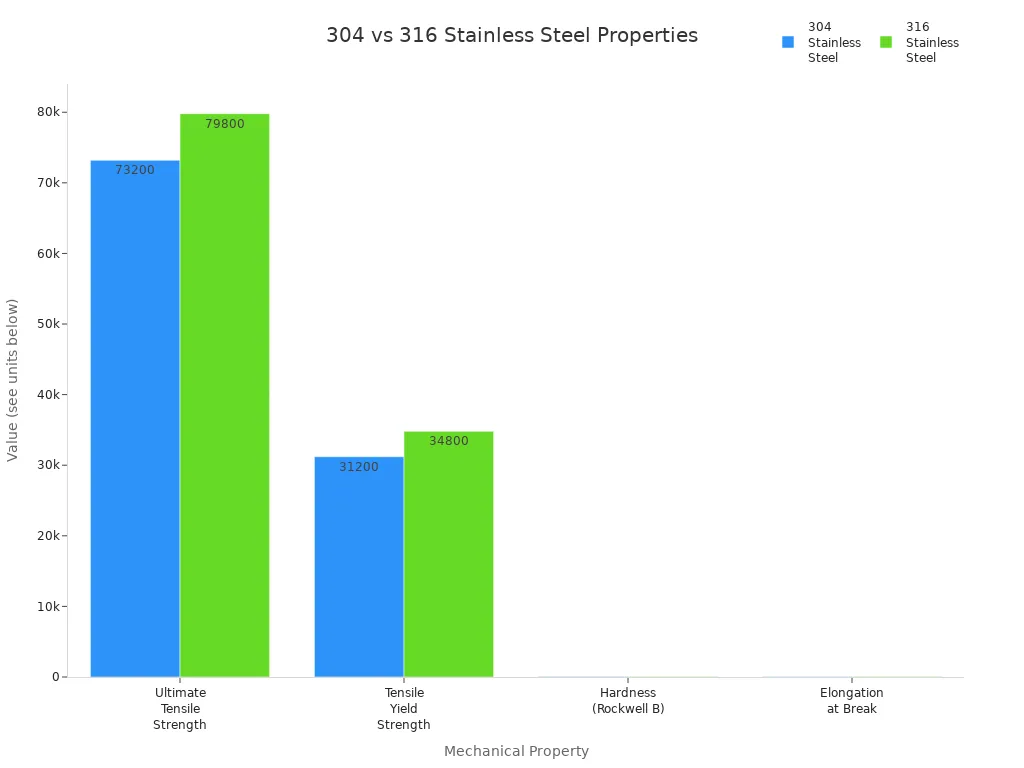

| Mechanical Property | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Ultimate Tensile Strength | 73,200 psi | 79,800 psi |

| Tensile Yield Strength | 31,200 psi | 34,800 psi |

| Hardness (Rockwell B) | 70 | 80 |

| Elongation at Break | 70% | 60% |

316 stainless steel is stronger and harder. 304 stainless steel can stretch more before it breaks.

304 stainless steel can stop rust in most normal places.

316 stainless steel is even better at stopping rust, especially near the sea or with chemicals.

The molybdenum in 316 stainless steel helps stop small holes and cracks from salt and strong chemicals.

Both types are good at fighting rust, but 316 stainless steel works best in hard places.

| Stainless Steel Type | Price Range (USD/kg) | Key Cost Factors | Corrosion Resistance | Typical Premium Over 304 |

|---|---|---|---|---|

| 304 | $1.50 - $2.50 | Lower nickel content, no molybdenum | Moderate corrosion resistance | Baseline |

| 316 | $3.00 - $4.00 | Higher nickel content, 2-3% molybdenum, more complex manufacturing | Superior corrosion resistance, especially in harsh environments | 40-60% higher |

316 stainless steel costs more because of what is in it and how well it stops rust. The extra money is worth it if you need to fight a lot of rust.

304 stainless steel is known for being strong and reliable. It has about 18% chromium and 8% nickel. This mix helps it fight rust. It is safe for food and medical tools. It does not have molybdenum. So, it does not stop rust as well as some other types. But it still works well inside and outside.

The table below shows how strong 304 stainless steel is:

| Property | 304 Stainless Steel (Annealed) |

|---|---|

| Yield Strength | Minimum 30 ksi (207 MPa) |

| Tensile Strength | Minimum 75 ksi (517 MPa) |

| Elongation | Minimum 40% |

| Hardness | Maximum 92 Rockwell B |

304 stainless steel is easy to weld. Most welding methods work without extra steps. It is also easy to shape and join. This helps when making kitchen tools, tanks, and car parts. It can handle heat well. It stays strong even when it gets hot.

Note: 304 stainless steel is simple to clean. It keeps looking good for a long time. That is why people use it where you can see it.

316 stainless steel has something special. It has about 2% molybdenum. This makes it different from 304 stainless steel. Molybdenum helps it stop rust from salt and chemicals. So, 316 stainless steel is best for boats, chemical plants, and medicine factories.

The table below shows how strong 316 stainless steel is:

| Mechanical Property | Typical Value | Notes |

|---|---|---|

| Tensile Strength | ~90,000 psi | High resistance to breaking under tension |

| Yield Strength | ~85,000 psi | Withstands stress before permanent change |

| Elongation at Break | 40% - 50% | Good ability to stretch before breaking |

| Hardness (Brinell) | 150 - 163 | Varies with form |

| Impact Resistance | Superior | Handles shocks well |

316 stainless steel is also easy to weld. Many welding ways work well. It stays strong after welding. It can handle high heat. It is good for making things with tricky shapes.

Tip: 316 stainless steel is great for tough places. It works well where there is a lot of rust or chemicals.

304 stainless steel does a good job stopping rust in most places. It works well in kitchens, food factories, and inside buildings. Chromium and nickel help make a thin shield on the surface. This shield keeps out water and air. That slows down rust.

304 stainless steel can stop rust from water and weak acids.

It does not work as well near the ocean or where there is salt.

Salt can break the shield and cause small holes and cracks.

These holes show up as tiny spots, mostly near the sea or where there is a lot of salt.

Rust can also happen in small spaces where salty water gets trapped.

Cracks from stress may happen if it gets hotter than 140 °F.

304 stainless steel can handle some acids, but not strong ones.

People should not use 304 stainless steel near the sea or where there is a lot of salt. It is not the best for chemical plants or places with strong acids. In these tough places, another type is better.

316 stainless steel is much better at stopping rust. Molybdenum makes it stronger against rust. This element helps the shield stay strong in hard places. 316 stainless steel stops holes and cracks better than 304 stainless steel, especially near the sea.

316 stainless steel works well in saltwater, on roads with salt, and in places with lots of chemicals. It can handle many acids, like sulfuric and hydrochloric acid. People in boat work, chemical plants, and pools often pick 316 stainless steel. It stays strong and looks good, even in rough places.

Tip: If your project is near the sea, in a chemical plant, or in water, 316 stainless steel is the best for stopping rust and lasting a long time.

The price of stainless steel changes with the metals inside. Grade 304 stainless steel has nickel. Grade 316 stainless steel has nickel and molybdenum. Nickel and molybdenum prices can go up or down. This happens because of mining problems or export laws. When these metals cost more, stainless steel gets more expensive. Grade 304 usually costs about $2,500 to $3,200 per ton. Grade 316 costs more, from $3,500 to $4,000 per ton. The higher price for 316 is because of molybdenum. Molybdenum helps 316 stainless steel fight rust from salt and chemicals. The final price also depends on world markets, energy costs, and where it is made.

Tip: If your project does not deal with strong chemicals or salt, 304 stainless steel can help you save money. For hard places, paying more for 316 stainless steel can be a good idea.

Picking 304 or 316 stainless steel is about more than just the first price. The right choice can save money later. 304 stainless steel works well outside in most places. It might rust if there is a lot of salt or chemicals. 316 stainless steel lasts longer in these tough places. It needs less cleaning and fixing. The table below shows how each type does outside:

| Aspect | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Corrosion Resistance | Good in normal outdoor places; can rust near salt or chemicals | Great at stopping rust from saltwater and strong chemicals |

| Environmental Suitability | Best for normal weather and most outdoor use | Best for places near the sea or with harsh weather |

| Durability & Lifespan | Lasts long in easy places; rust can make it weaker in tough spots | Lasts longer in hard places |

| Maintenance | Easy to care for in normal areas; may need more work near salt | Needs less care because it fights rust better |

| Cost Consideration | Cheaper at first; may cost more to fix in hard places | Costs more at first; saves money over time |

If your project is in a place with mild weather, 304 stainless steel can keep costs down. If it is near the sea or in a chemical plant, 316 stainless steel is the best choice for saving money in the long run. This means fewer repairs and a longer life for your project.

304 stainless steel is used in many things. It is strong and does not rust easily. It is safe for food. People also call it 18/8 stainless steel because it has 18% chromium and 8% nickel. You can find it in factories and at home.

Builders use 304 stainless steel for walls, railings, and outside trim. These parts need to look nice and not rust.

Car makers use it for car trim, wheel covers, and exhausts. These parts must last and handle hard use.

Food companies use 304 stainless steel for sinks, pots, tanks, and belts. It is easy to clean and keeps food safe.

Plumbers use it for pipes, valves, and water tanks. It does not rust in wet places.

Hospitals use 304 stainless steel for tools and cleaning machines. It keeps things safe for patients.

Many home machines like fridges, washers, and dishwashers have 304 stainless steel parts.

This type is also in heat changers, wall panels, and bolts. It is used a lot in factories because it works well in many ways.

316 stainless steel is best where there are lots of chemicals or rust. Molybdenum makes it even better at stopping rust, especially near the sea or with chemicals.

Many jobs need 316 stainless steel for important machines. Chemical plants use it for tanks and pipes. These must handle strong chemicals every day. Boat makers use 316 stainless steel for boat parts, docks, and platforms. These parts are always in saltwater.

Factories use it for medicine machines, food machines, and pumps. Power plants and nuclear places pick 316 stainless steel because it is strong and fights chemicals. Oil and gas companies use it for big machines and pipes.

Tip: 316 stainless steel is best for machines near the sea, in chemical plants, or in tough places where you need it to last.

316 stainless steel is used when machines must work well and last a long time in hard places.

Picking the right stainless steel grade takes careful planning. Every place has its own problems. Before you choose, project leaders should think about some main questions:

What type of environment will the equipment face?

If the project is near the ocean or in a chemical plant, it needs more corrosion resistance. 316 stainless steel is best here. It stands up to salt and strong chemicals.

What chemicals will the equipment contact?

Some places have acids or strong cleaners. 316 stainless steel does better with chemicals than 304. This is important for food, medicine, or factory machines. It helps keep things safe and working well.

How important is corrosion resistance for long-term use?

Corrosion can make equipment break sooner. 304 stainless steel works well inside and in gentle outdoor places. In tough spots, 316 stainless steel lasts longer and needs fewer repairs.

What is the project budget?

304 stainless steel costs less at first. But in places with lots of rust, 316 stainless steel saves money later. It needs fewer fixes and replacements.

What mechanical properties are needed?

Some jobs need metal that bends easily. Others need it to be strong or hard. 304 stainless steel bends better. 316 stainless steel is stronger and harder, so it wears out less.

Does the project require special fabrication or welding applications?

Both grades are good for welding. But 316 stainless steel can wear out tools faster. Project leaders should check if suppliers can handle this.

Are there industry standards or certifications required?

Many factories and chemical plants need materials that meet strict rules. Always check for certifications like ASTM or ISO.

Tip: Picking the wrong grade can cost more and make equipment work badly. Many people pick 304 stainless steel to save money. But in tough places, this means more repairs and replacements.

A simple checklist can help you pick between 304 and 316 stainless steel. Use the table below to see what you need and match the right grade to your project:

| Question | Choose 304 Stainless Steel | Choose 316 Stainless Steel |

|---|---|---|

| Will the equipment face saltwater, seawater, or salt spray? | ❌ | ✅ |

| Will the equipment contact strong chemicals or acids? | ❌ | ✅ |

| Is the environment mostly indoors or mild outdoor? | ✅ | ✅ |

| Is initial cost the main concern? | ✅ | ❌ |

| Is long-term durability and low maintenance important? | ❓ | ✅ |

| Does the project need high corrosion resistance for industrial use? | ❌ | ✅ |

| Will the equipment undergo frequent cleaning with harsh agents? | ❓ | ✅ |

| Are high mechanical strength and hardness required? | ❓ | ✅ |

| Is easy forming or shaping needed? | ✅ | ❓ |

| Are there strict industry standards or certifications to meet? | ✅ | ✅ |

Legend:

✅ = Recommended

❌ = Not recommended

❓ = Possible, but check project details

Note: In places with lots of rust, 316 stainless steel costs more at first but saves money over time. Its strong corrosion resistance means fewer repairs and replacements. This makes it a better deal than 304 stainless steel in the long run.

Key questions to ask before choosing:

Will the equipment face salt, chemicals, or harsh cleaning?

Is long-term durability more important than saving money now?

Does the project require specific certifications or standards?

What mechanical properties does the equipment need?

Can the supplier provide the right grade with proper quality control?

Checklist for chemical processing applications:

Corrosion resistance, including resistance to stress corrosion cracking, crevice corrosion, pitting, and intergranular attack

Oxidation and sulfidation resistance for high-temperature environments

Suitable mechanical properties at service and ambient temperatures

Compatibility with fabrication and cleaning procedures

Stable properties throughout the equipment's service life

Selection of the proper stainless steel grade for corrosion resistance and durability

Supplier capabilities, including quality control, certifications, and adherence to standards

Picking the right stainless steel grade keeps equipment safe, saves money, and makes sure it works well. Always match the material to the place, chemicals, and what the project needs.

304 stainless steel is good for most jobs. It costs less and does not rust in normal places. 316 stainless steel is better for hard places. It works well near saltwater or chemicals. This is because it has molybdenum and more nickel.

| Aspect | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Cost | Lower | Higher |

| Corrosion Resistance | Good | Superior |

| Best Use | General environments | Marine, chemical, medical |

If your project is in a tough place, pick 316 stainless steel. If you are not sure, ask a trusted supplier. This helps you choose the right material and makes your project last longer.