English

T: +86-0731-85185770

E: enquiry@qilumetal.com

E: enquiry@qilumetal.com

No. 18 Xiangfu Middle Road,Yuhua District, Changsha City

Views: 0 Author: Site Editor Publish Time: 2025-08-10 Origin: Site

Wear resistant steel is very strong and lasts a long time. This makes it very important in modern manufacturing. Mining, construction, and farming use abrasion-resistant steel a lot. It helps machines last longer and need less fixing. In 2024, the world market for abrasion resistant steel plates was $14.62 billion. Mining made up more than 35% of these sales.

| Year | Market Value (USD Billion) | CAGR |

|---|---|---|

| 2024 | 14.62 | 5.48% |

| 2032 | 22.40 | 5.48% |

High abrasion resistance and toughness help companies stop machines from breaking down. This also helps them work better and faster.

High wear resistant steel is very strong. It lasts much longer than regular steel. This makes it great for hard jobs in mining, construction, farming, and recycling.

The steel’s hardness and toughness protect machines from damage. It helps stop breakdowns. It also lowers maintenance costs. This helps companies save time and money.

Special alloy elements like chromium, molybdenum, and vanadium make the steel stronger. They help the steel resist wear. They also improve impact toughness for better performance.

Picking the right steel grade depends on what the job needs. You must balance hardness, toughness, cost, and how easy it is to make things. This helps get the best results.

Handling the steel the right way is important. Preheating before welding helps. Using special cutting tools keeps the steel strong. It also keeps machines safe during manufacturing.

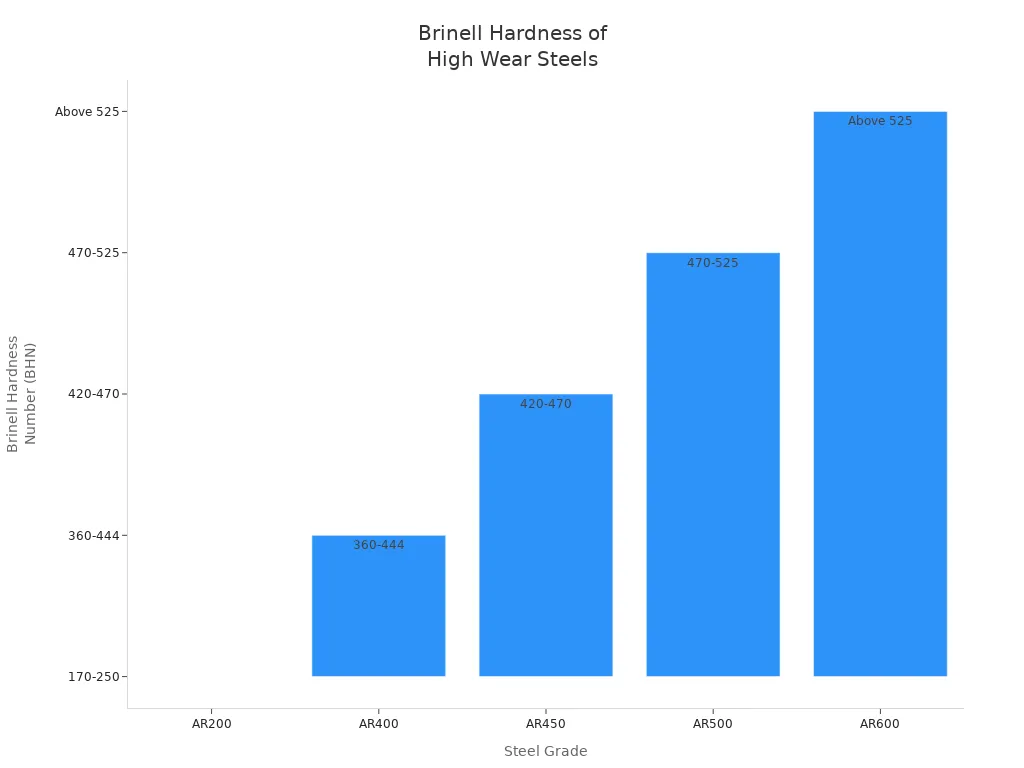

Hardness and toughness are very important for abrasion-resistant steel. These steels are much harder than regular structural steels. The table below shows how hard different steel grades are:

| Steel Type | Hardness Scale | Hardness Range (Typical) |

|---|---|---|

| AR400 (Wear Resistant) | Brinell Hardness Number | 360 - 440 BHN |

| AR450 (Wear Resistant) | Brinell Hardness Number | 430 - 480 BHN |

| AR500 (Wear Resistant) | Brinell Hardness Number | 460 - 544 BHN |

| AR600 (Wear Resistant) | Brinell Hardness Number | 570 - 625 BHN |

| A36 (Structural Steel) | Rockwell B Scale | Max B68 |

| 1018 (Structural Steel) | Rockwell B Scale | Max B72 |

| 1045 (Structural Steel) | Rockwell B Scale | Max B90 |

Abrasion-resistant steel is known for being very hard and strong. Tests show that having both hardness and toughness helps stop damage from impacts. Steels with the same hardness but more toughness last longer when hit. Special ways of making the steel help balance these features. This gives the steel great toughness and helps it handle strong impacts.

Abrasion-resistant steel can handle much more wear than regular steel. The chart below shows the Brinell Hardness for different high wear resistant steel grades:

This steel gets its high abrasion resistance from its hardness and structure. Studies show these steels can last up to four times longer than regular steels. Because of this, companies can use thinner and lighter parts. These parts still protect machines well. Equipment can carry more and does not need fixing as often. High impact resistance also helps stop sudden breaks in tough places.

The mix of elements in wear resistant steel affects how it works. Important elements are carbon, chromium, molybdenum, vanadium, manganese, and nickel. The table below explains what each element does:

| Alloying Element | Effect on Wear Resistant Steel Performance Metrics |

|---|---|

| Carbon (C) | Increases hardness and strength; higher carbon improves wear resistance but reduces ductility. |

| Chromium (Cr) | Enhances hardness, tensile strength, corrosion resistance, and hardenability, improving wear resistance. |

| Molybdenum (Mo) | Improves hardenability, wear resistance, corrosion resistance, and high-temperature strength. |

| Vanadium (V) | Refines grain structure, increases strength and toughness, improves wear resistance and shock resistance. |

| Manganese (Mn) | Acts as a deoxidant, increases hardenability and tensile strength, contributes to wear resistance. |

| Nickel (Ni) | Enhances toughness, impact strength, and low-temperature fracture toughness, indirectly supporting wear resistance. |

Chromium and molybdenum make hard carbides that help stop wear. Vanadium and manganese make the steel stronger and better at handling hits. Nickel makes the steel tougher, even when it is cold. All these elements work together to give abrasion-resistant steel its high wear and impact resistance. This makes it great for tough jobs.

Mining and quarrying need strong equipment. Machines work in rough places with lots of rocks. Abrasion-resistant steel helps protect machines from damage. It is used in many parts like:

Dump truck bodies

Chutes and hoppers

Conveyor systems

Excavator buckets

Bulldozer blades

Grader blades

Crushers, screens, and wear liners

These parts get hit and scratched by rocks and minerals. Abrasion-resistant steel makes them last longer. This means fewer replacements and less time fixing machines. For example, AR500 steel in crusher liners lasts twice as long as AR400 steel. The table below shows what happens when you use better steel:

| Aspect | Impact of Using AR500 Steel Compared to AR400 Steel |

|---|---|

| Operational Lifespan | Service life doubled (2.4 to 4.8 years) |

| Maintenance Frequency | Replacement frequency reduced by 50% |

| Downtime Events | 50% fewer downtime events |

| Procurement Costs | Reduced by 50% |

| Processing Efficiency | 50% less machining and installation labor |

| Daily Operational Costs | 40% lower |

| Hardness Uniformity | ≥90% hardness uniformity through thickness |

| Environmental Benefits | 50% lower carbon footprint |

| Application Examples | Crusher liners, chutes, dump truck liners |

Mining companies save money and time. Abrasion-resistant steel is important for tough jobs.

Construction sites use heavy machines every day. These machines work with dirt, rocks, and other hard things. Abrasion-resistant steel is found in:

Bulldozers

Excavators

Dump trucks

Backhoes

Cement mixers

Compactors

Buckets and cutting edges

Equipment liners

Structural beams

These parts rub against rough surfaces and get hot. Abrasion-resistant steel keeps them strong and stops them from breaking. The table below explains how steel helps machines last longer:

| Property | Role in Durability and Performance | Impact on Downtime and Repair Costs |

|---|---|---|

| High Yield Strength | Prevents permanent deformation under heavy loads | Machinery parts resist warping and bending, reducing failures |

| High Tensile Strength | Resists cracking and fractures under impact and extreme forces | Prevents breakage, lowering frequency of repairs |

| Elongation (Ductility) | Absorbs impact energy without cracking or shattering | Extends service life, reduces maintenance intervals |

Special alloys like ENDURA help machines work longer. Companies have fewer problems and save money.

Tip: Construction managers pick abrasion-resistant steel for hard jobs. This helps machines work more and break less.

Farm machines work in fields with dirt and rocks. They carry heavy loads and face tough weather. Abrasion-resistant steel is used in many parts:

| Machinery Part | Steel Types Used | Reason for Use (Wear Resistance & Durability) |

|---|---|---|

| Tractor Frames | High-strength steel, hot-rolled steel | Strength, durability, resistance to harsh field conditions |

| Combine Parts | Galvanized steel, high-strength steel | Strength and corrosion resistance for continuous harvesting |

| Hay Equipment | Galvanized steel, hot-dipped galvanized steel | Longevity and reliability under various conditions |

| Sprayers/Spreaders | High-strength steel, hot-rolled steel | High resistance to corrosion and wear |

| Ploughs/Plows | High-strength steel, hot-rolled steel | Durability and strength for harsh soil |

| Rotavators | Hot-rolled steel, high-strength steel | Strength and wear resistance for soil turning |

| Disc Harrows | High-strength steel, hot-rolled steel | Wear resistance for breaking up soil clods |

| Levelers | High-strength steel, galvanized steel | Precision soil leveling with durability |

Strong steel makes farm parts last longer. Less fixing is needed. Gas carbonitriding treatment on plowshares helps them wear less. TiN coatings and hard chrome plating make them even stronger. Farmers get more work done and spend less on repairs.

Recycling centers use machines that crush and sort trash. These machines hit and rub against hard things all the time. Abrasion-resistant steel is used in:

Hammers and hammer pins

Liner plates

Cyclones

Grapples and buckets

Trommel screens

Shredders and crushers

Sorting drums

Special steels like Hardox® and Toolox® last a long time. They help machines work better and break less. For example, a paper mill used abrasion-resistant steel in bark hogs and conveyors. They processed more tons each day and their machines lasted longer. This saved money and time.

Note: Custom steel parts help recycling centers work faster. They make waste management easier and cheaper.

AR400 and AR500 are popular abrasion-resistant steel grades. AR400 is easy to work with and shape. It can handle impacts and wear outside. Chromium in AR400 helps stop rust. Workers can weld and bend AR400 without much cracking. AR500 is stronger than AR400 by about 25 percent. It has higher yield strength and is tougher. Manganese in AR500 makes it better at handling cuts. AR500 is hard all the way through. It stays strong even when hit hard or used in rough places. But AR500 is harder to weld and cut.

| Property | AR400 Steel Characteristics | AR500 Steel Characteristics |

|---|---|---|

| Hardness | Approximately 400 Brinell (HB); moderate to heavy wear resistance | Approximately 500 Brinell (HB); very high abrasion resistance |

| Toughness | Higher toughness and ductility; less prone to cracking | Lower toughness; more prone to cracking |

| Wear Resistance | Moderate to heavy wear resistance | Very high wear resistance suitable for extreme conditions |

| Machinability | Easier to machine due to lower hardness | More difficult to machine; requires specialized tools |

| Weldability | Good weldability with proper precautions | Weldable but requires strict heat control to maintain properties |

Many industries use these steels in different ways. Construction uses them in bulldozers and beams. Mining uses them in buckets and truck liners. Farms use them for plow blades and grain tools.

Some jobs need special steel with extra features. Grades like ASTM A514, Elmax Steel, and Eglin Steel are made for these needs. ASTM A514 is strong and resists wear. Big machines and building parts use this steel. Elmax Steel fights both wear and rust. It is good where both are a problem. Eglin Steel is tough and resists wear for tools.

| Steel Grade / Type | Key Properties | Unique Applications | Reason for Selection / Benefits |

|---|---|---|---|

| AR400, AR500, AR600 | High hardness, excellent wear resistance | Excavator buckets, steel plates, armored vehicles | Withstands abrasive materials, extends component life |

| ASTM A514 | High strength, abrasion resistance | Heavy machinery components, structural parts | Toughness and wear resistance for heavy-duty use |

| Elmax Steel | Exceptional wear and corrosion resistance | Niche applications needing both properties | Specialized alloying for combined benefits |

| Eglin Steel | High wear resistance, toughness | Industrial tools and components | Tailored for high abrasion and impact conditions |

Special steel grades are also used in trains and big trucks. These steels help parts last longer and need less fixing.

Picking the right steel grade depends on many things. Engineers must choose between hardness and toughness. Harder steel lasts longer but can break easier. Surface hardening can make the outside tough and keep the inside strong. Weather and temperature also matter. Cost and if the steel is easy to get are important too. Some steels cost more or are hard to find. The best steel matches the job, the place it will be used, and the budget.

Tip: Always think about how the steel will be used, where it will go, and the price to get the best results.

Picking the right abrasion resistant steel means knowing what each job needs. Every industry has its own problems to solve. Mining machines need steel that is very hard and tough. This helps them handle rocks and strong hits. Construction tools need steel that is not too hard but can bend without breaking. The table below shows how jobs change which steel is best:

| Application Requirement | Key Steel Properties | Suitable Grades |

|---|---|---|

| High abrasion and heavy impact | High hardness, toughness | AR500, Hardox 500 |

| Low to medium wear | Moderate hardness, toughness | AR400, Hardox 400 |

| High-temperature environments | Heat, oxidation resistance | WELDOX series |

| Corrosive environments | Corrosion resistance | 304 stainless steel |

Tip: Pick steel that fits the job. This helps machines last longer and work better.

It is important to think about both cost and how well the steel works. Stronger steels cost more at first. But they save money later. These steels help machines break less and need fewer repairs. Hardness, toughness, and wear resistance are important things to check. Companies should look at supplier papers and test results to make sure the steel is good.

Hardness tells how well steel fights wear.

Toughness shows how much force steel can take before it breaks.

What is in the steel changes how strong and easy to weld it is.

Paying more for strong steel at the start can save money later. This is because machines need fewer fixes and last longer.

Making things with high abrasion resistant steel is harder than with regular steel. It is tough to cut, bend, and weld these steels. Problems like cracking, tool damage, and bending can happen when welding. To fix these problems, workers should:

Heat the steel before welding to stop cracks.

Use carbide tools and keep them cool when cutting.

Clean the steel well before working on it.

Note: Doing these steps helps keep steel strong. It also makes machines safer and more reliable.

High wear resistant steel is very strong and useful in many ways. Studies show that special treatments and mixing metals make it harder and tougher. This helps machines last longer and work better. When companies pick the right steel for each job, their machines break less and cost less to fix.

Picking abrasion-resistant steel helps machines work well for a long time. It is a good choice for any industry, even in tough places.

Wear resistant steel has special alloys like chromium and manganese. These elements make the steel harder and tougher. Regular steel is not as strong or durable. It does not resist wear as well.

Manufacturers use this steel in mining, construction, agriculture, and recycling. Equipment such as dump truck bodies and excavator buckets use it. Crusher liners also benefit from its strength. These parts last longer and work better.

Companies have fewer breakdowns and parts last longer. Machines need repairs less often. This means less downtime and saves money. Replacement parts and labor cost less.

Workers can weld or cut this steel with special tools. They need to use certain techniques to avoid cracks. Preheating and slow cooling help a lot. Carbide-tipped tools are best for cutting.