Welcome to Qilu 4140 Steel Excellence!

Qilu Steel stands as a premier manufacturer of 4140 steel, dedicated to providing high-performance quenched and tempered alloy steel solutions for demanding industrial applications. Our 4140 steel series represents the pinnacle of metallurgical engineering, delivering exceptional mechanical properties, superior toughness, and outstanding wear resistance while maintaining the highest standards of quality and consistency.

Introduction to 4140 Steel

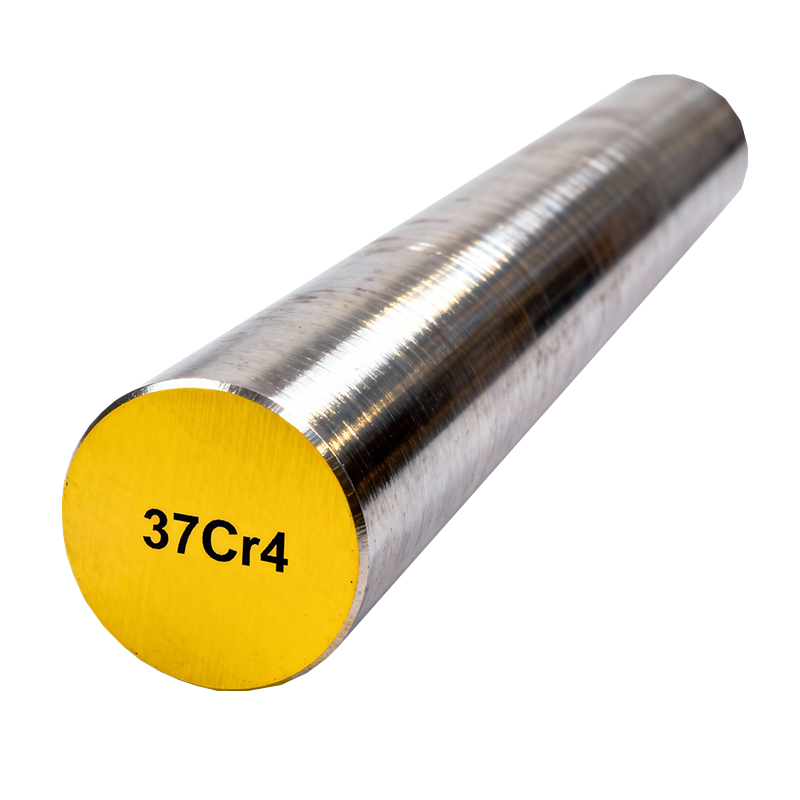

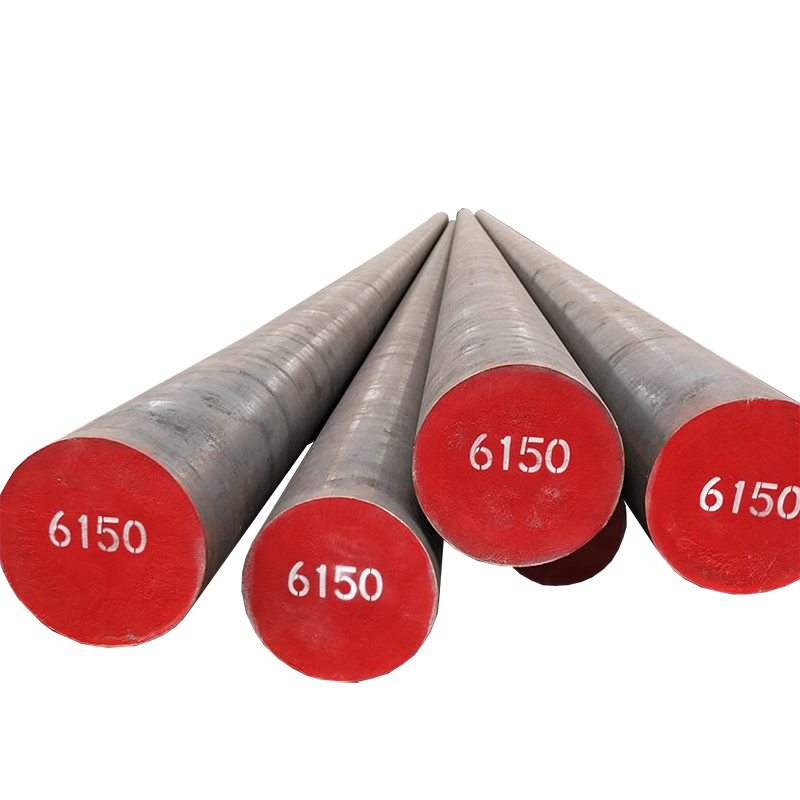

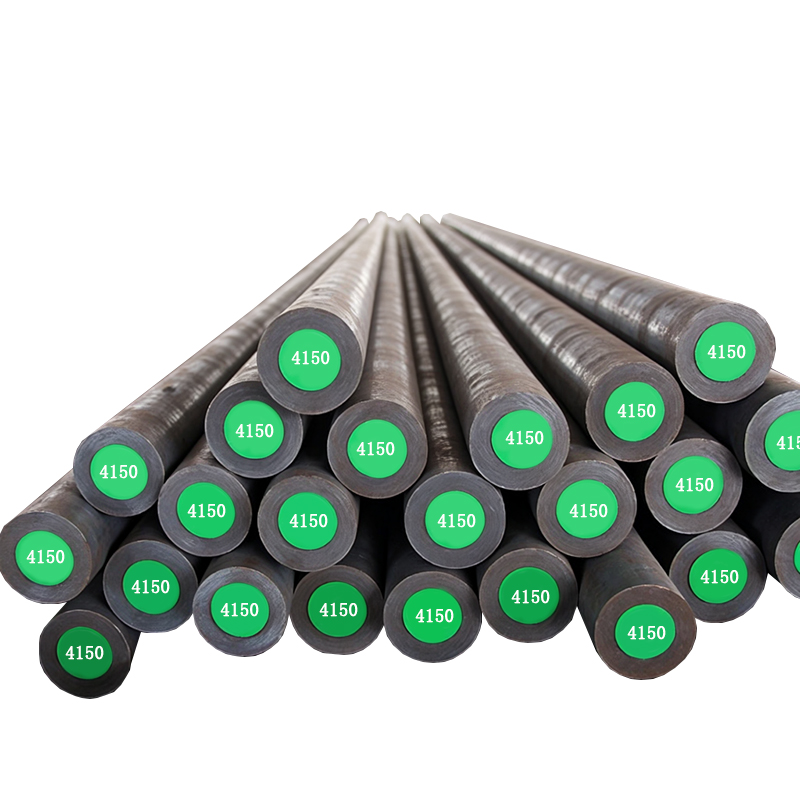

Our extensive 4140 steel collection features multiple product forms engineered to meet diverse manufacturing requirements. This alloy steel undergoes strict quenching and tempering (QT) processes, making it suitable for demanding applications across industries like automotive, aerospace, and heavy machinery. From precision machined bars to large forged components, Qilu offers 4140 steel solutions that perfectly match your application needs.

Product Center – 4140 Steel Collection

Why Choose Qilu 4140 Steel

Discover the strength and versatility of AISI 4140 steel for your next project!

Exceptional Strength and Durability

AISI 4140 steel offers superior mechanical properties after quenching and tempering, delivering high tensile and yield strength combined with excellent ductility. This makes it an ideal choice for load-bearing and high-stress components where both strength and toughness are critical.

Versatile Heat Treatment and Supply Options

The steel responds exceptionally well to various heat treatments, from soft annealing for easier machining to induction hardening for wear-resistant surfaces. Additionally, it is available in a wide range of sizes and forms—including cold drawn, hot rolled, and hot forged bars—ensuring adaptability to diverse manufacturing requirements.

Contact Us

Application Scenarios – 4140 Steel Solutions

Company Advantages

Export Experience

With over 12 years of experience in steel exports, we have built a robust international trade network. Our team is highly skilled in handling global logistics, customs clearance, and compliance requirements, ensuring that orders reach customers safely and on time.

Forging Experience

Leveraging more than 30 years of expertise in steel forging, we deliver components with superior mechanical properties, including excellent strength, toughness, and fatigue resistance. Our advanced forging processes are optimized for precision, consistency, and performance in demanding applications.

Inventory Level

We maintain over 20,000 tons of steel in stock across a wide range of sizes and grades. This extensive inventory allows us to respond quickly to customer orders, provide flexible solutions, and support both large-scale industrial projects and smaller specialized requirements.

Global Customer Base

Our customers span Europe, North America, South America, Asia, Africa, and Australia, including key markets such as Germany, the United Kingdom, the United States, Brazil, Russia, and the United Arab Emirates. Long-term partnerships with these clients demonstrate our reliability, quality assurance, and ability to meet diverse industrial demands worldwide.

Download

- Name

- Summary

- Category

- Update

- Size

- Downloads

- Thumbnail

- Download

- Copy Link

- JIS-G4404 2006-Japanese-Alloy Tool Steels

- JIS Standard

- 2025-04-02

- 786KB

- 7

-

- Download

- Copy Link

- JIS-G4401 2000-Japanese-Carbon Tool Steels

- JIS Standard

- 2025-04-02

- 969KB

- 2

-

- Download

- Copy Link

- JIS-G4303 2005-Japanese-Stainless Steel Bars

- JIS Standard

- 2025-04-02

- 3.20MB

- 3

-

- Download

- Copy Link

- JIS-G4103 1979-Japanese-Nickel Chromium Molybdenum Steels

- JIS Standard

- 2025-04-02

- 573KB

- 1

-

- Download

- Copy Link

- JIS-G4051 2009-Japanese-Carbon Steels for Machine Structural Use

- JIS Standard

- 2025-04-02

- 234KB

- 1

-

- Download

- Copy Link

- JIS-G3521 1991-Japanese-Hard Drawn Steel Wires

- JIS Standard

- 2025-04-02

- 147KB

- 1

-

- Download

- Copy Link

- JIS-G3463 2006-Japanese-Stainless Steel Boiler and Heat Exchanger Tubes

- JIS Standard

- 2025-04-02

- 2.54MB

- 2

-

- Download

- Copy Link

- JIS-G3459 2004-Japanese-Stainless Steel Pipes

- JIS Standard

- 2025-04-02

- 1.25MB

- 1

-

- Download

- Copy Link

- JIS-G3194 1998-Japanese-Dimensions-Mass and Permissible Variations of Hot Rolled

- JIS Standard

- 2025-04-02

- 281KB

- 2

-

- Download

- Copy Link

- JIS-G3191 2002-Japanese-Dimensions-Mass and Permissible Variations of Hot Rolled

- JIS Standard

- 2025-04-02

- 294KB

- 6

-

- Download

- Copy Link

FAQs

Related Blogs

-

Image Source: unsplashYou see metal tools break fast in hard jobs. Wear-resistant steel lasts much longer in tough places. Many companies use this steel to keep machines working.IndustryPrimary ApplicationsConstruction and MiningWear liners, rock breakers, bulldozers, excavator bucket linersTransporBlogs

Image Source: unsplashYou see metal tools break fast in hard jobs. Wear-resistant steel lasts much longer in tough places. Many companies use this steel to keep machines working.IndustryPrimary ApplicationsConstruction and MiningWear liners, rock breakers, bulldozers, excavator bucket linersTransporBlogs -

Image Source: pexelsYou need a material that can do hard work. It should not lose its shape or strength. Spring steel is different from other strong materials. It has special features. Many industries use spring steel. For example, cars and airplanes need it. They use it for important parts. These pBlogs

Image Source: pexelsYou need a material that can do hard work. It should not lose its shape or strength. Spring steel is different from other strong materials. It has special features. Many industries use spring steel. For example, cars and airplanes need it. They use it for important parts. These pBlogs -

Image Source: pexelsYou use spring steel often, even if you do not know it. Think about the strong springs in your car. Or think about the sharp blade in your garden shears. Spring steel is special because it bends and goes back to its shape. This makes it great for parts that get used a lot. Its stBlogs

Image Source: pexelsYou use spring steel often, even if you do not know it. Think about the strong springs in your car. Or think about the sharp blade in your garden shears. Spring steel is special because it bends and goes back to its shape. This makes it great for parts that get used a lot. Its stBlogs -

Image Source: pexelsYou want your machines to last longer. You want to fix them less often. You want them to work better. Wear-resistant steel can help with these things. Many businesses use over 45 million tons of wear-resistant steel each year. They do this because it saves money.BenefitImpactEquiBlogs

Image Source: pexelsYou want your machines to last longer. You want to fix them less often. You want them to work better. Wear-resistant steel can help with these things. Many businesses use over 45 million tons of wear-resistant steel each year. They do this because it saves money.BenefitImpactEquiBlogs

Keep In Touch With Us

Develop superior components with Qilu's premium 4140 steel solutions. Contact us today for expert consultation and competitive quotations.

Tel: +86-0731-85185770

E-mail:enquiry@qilusteel.com