English

T: +86-0731-85185770

E: enquiry@qilumetal.com

E: enquiry@qilumetal.com

No. 18 Xiangfu Middle Road,Yuhua District, Changsha City

| Availability: | |

|---|---|

| Quantity: | |

51CrV4 / 1.8159 is a widely used spring steel belonging to the European standard EN 10083-3 and EN 10250-3. It is primarily employed in the manufacturing of high-stress springs and components for the automotive, railway, and machinery industries. Consequently, it has equivalent grades in various international standards, such as AISI 6150 from the American standard ASTM A29, SUP10 from the Japanese standard JIS G4801, 50CrVA from the Chinese standard GB/T 1222, and 735A50 from the British standard BS 970.

51CrV4 is a Cr-V steel series, characterized by a carbon content of 0.47-0.55%. After oil quenching and tempering, it achieves an excellent combination of high fatigue strength, good toughness, and outstanding elastic properties, making it particularly suitable for applications requiring high stress resistance and durability.

1: Steel equivalent

Country | China | Japan | USA | Europe | British |

Standard | GB/T 1222 | JIS G4801 | ASTM A29 | EN10083-3 | BS 970 |

Grade | 50CrVA | SUP10 | 6150 | 51CrV4/1.8159 | 735A50 |

2: Chemical composition

Grade | C | Si | Mn | P | S | Cr | V |

| 50CrVA | 0.46-0.54 | 0.17-0.37 | 0.50-0.80 | 0.025Max | 0.025Max | 0.8-1.1 | 0.1-0.2 |

| SUP10 | 0.47-0.55 | 0.15-0.35 | 0.65-0.95 | 0.030Max | 0.030Max | 0.8-1.1 | 0.15-0.25 |

| 6150 | 0.48-0.53 | 0.15-0.35 | 0.70-0.90 | 0.035Max | 0.040Max | 0.8-1.1 | 0.15Min |

| 51CrV4/1.8159 | 0.47-0.55 | 0.40Max | 0.70-1.10 | 0.025Max | 0.025Max | 0.9-1.2 | 0.10-0.25 |

3: Mechanical properties .

Mechanical properties for 51CrV4 quenching and tempering alloy steel.

Size range | Tensile strength | Yield strength | Alongation | Area of reduction | Impact value At RT/J |

d≤16 t≤8 | 1100-1300Mpa | 900Mpa Min | 9% Min | 40% Min | / |

16<d≤40 8<t≤20 | 1000-1200Mpa | 800Mpa Min | 10% Min | 45% Min | 30J Min |

| 40<d≤100 20<t≤60 | 900-1100Mpa | 700Mpa Min | 12% Min | 50% Min | 30J Min |

| 100<d≤160 60<t≤100 | 850-1000Mpa | 650Mpa Min | 13% Min | 50% Min | 30J Min |

| 160<d≤250 100<t≤160 | 800-950Mpa | 600Mpa Min | 13% Min | 50% Min | 30J Min |

Sampling and preparation of test pieces for 51CrV4 quenching and tempering steel.

1): According to EN10083-1, all samples shall be taken at a distance of 12.5mm below the heat treated surface

2): As stipulated in the contract between buyer and seller.

Mechanical properties for 51CrV4 open die forgings steel according to EN10250-3

Size range | Tensile strength | Yield strength | Alongation | Impact value at RT/J | ||

L | Tr | L | Tr | |||

d≤160 | 800Mpa Min | 600Mpa Min | 13% Min | 9% Min | 30J Min | 16J Min |

Remark: L= Longitudinal Tr = Transverse

Sampling and preparation of test pieces for steel forging.

1: According to EN10250-1, all samples shall be taken at a distance of 4/T below the heat treated surface (with a minimum of 20mm and a maximum of 80mm), and t/2 from the end (where t is the equivalent thickness of the thickness of the ruling section of the forging at the time of heat treatment.

2: As stipulated in the contract between buyer and seller.

4: Surface hardness and hardenability.

Heat Treatment | Hardness |

Soft annealed (+A) | HB248Max |

Quenched and tempred (+QT) | HRC28-32(Common Range) |

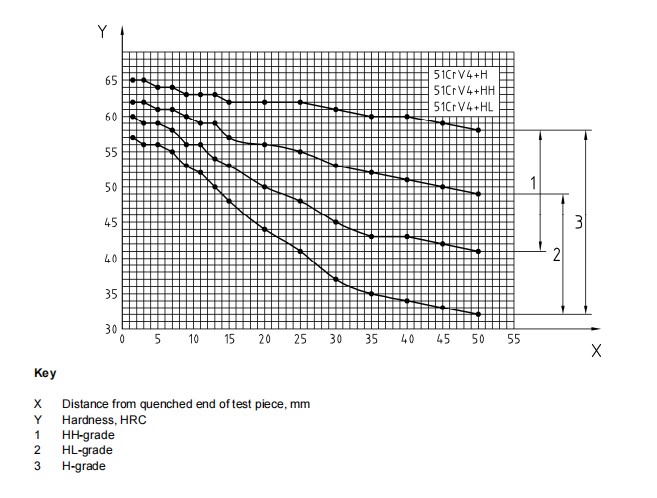

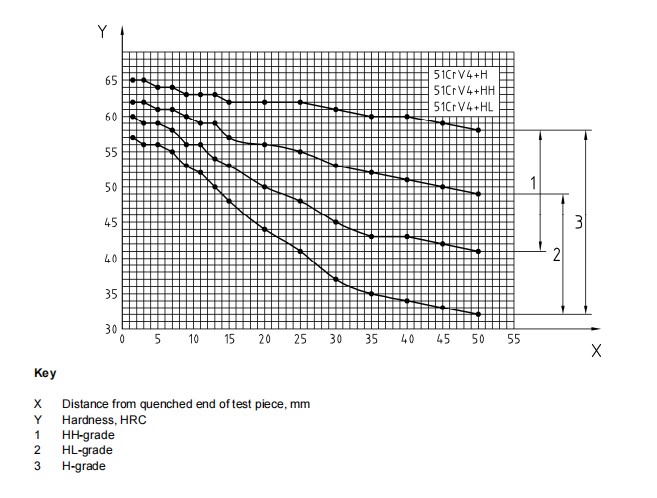

Where the steel is ordered by using the symbols for normal (+H) or restricted (+HL, +HH) hardenability requirements, the hardenability values should apply below:

Distance in mm from quenched end | ||||||||||||||||

Distance | 1.5 | 3 | 5 | 7 | 9 | 11 | 13 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | |

Hardness In HRC + H | max | 65 | 65 | 64 | 64 | 63 | 63 | 63 | 62 | 62 | 62 | 61 | 60 | 60 | 59 | 58 |

min | 57 | 56 | 56 | 55 | 53 | 52 | 50 | 48 | 44 | 41 | 37 | 35 | 34 | 33 | 32 | |

Hardness In HRC + HH | max | 65 | 65 | 64 | 64 | 63 | 63 | 63 | 62 | 62 | 62 | 61 | 60 | 60 | 59 | 58 |

min | 60 | 59 | 59 | 58 | 56 | 56 | 54 | 53 | 50 | 48 | 45 | 43 | 43 | 42 | 41 | |

Hardness In HRC + HL | max | 62 | 62 | 61 | 61 | 60 | 59 | 59 | 57 | 56 | 55 | 53 | 52 | 51 | 50 | 49 |

min | 57 | 56 | 56 | 55 | 53 | 52 | 50 | 48 | 44 | 41 | 37 | 35 | 34 | 33 | 32 | |

Scatter bands for the Rockwell - C hardness in the end quench hardenability test.

5: Supply size & Tolerance & Stock size

Product type | Size range | Length |

Cold drawn bar | Φ3-Φ80mm | 6000-9000mm |

Hot rolled bar | Φ16-Φ310mm | 6000-9000mm |

Hot forged bar | Φ100-Φ1200mm | 3000-5800mm |

Hot rolled plate/sheet | T:3-200mm; W:1500-2500mm | 2000-5800mm |

Hot Forged block | T: 80-800mm; W: 100-2500mm | 2000-5800mm |

Surface Finish | Turned | Milled | Grinding(Best) | Polished(Best) | Peeled(Best) | Black Forged | Black Rolled |

Tolerance | +0/+3mm | +0/+3mm | +0/+0.05mm | +0/+0.05mm | +0/+0.1mm | +0/+5mm | +0/+1mm |

Straighness | 1mm/1000mm max. | 3mm/1000mm max. | |||||

Qilu steel stock hot rolled bar and forged bars more than ten thousands tons every month, below our our stock size.

1): Stock diameter for hot rolled bar

16 | 18 | 20 | 22 | 24 | 25 | 26 | 27 | 28 | 30 | 31 | 32 | 33 | 35 | 36 |

38 | 39 | 40 | 42 | 45 | 46 | 48 | 50 | 52 | 55 | 56 | 58 | 60 | 62 | 63 |

65 | 68 | 70 | 72 | 75 | 78 | 80 | 82 | 83 | 85 | 87 | 90 | 95 | 100 | 105 |

110 | 115 | 120 | 125 | 130 | 135 | 140 | 145 | 150 | 155 | 160 | 170 | 180 | 190 | 200 |

210 | 220 | 230 | 240 | 250 | 260 | 270 | 280 | 290 | 300 | 310 |

2) : Stock diameter for hot forged bar

310 | 320 | 330 | 340 | 350 | 360 | 370 | 380 | 390 | 400 |

410 | 420 | 430 | 440 | 450 | 460 | 470 | 480 | 490 | 500 |

510 | 520 | 530 | 540 | 550 |

Since the stocks change everyday, if you want to know our stock available information, please contact our salesman.

6:Forging processing

Put the 51CrV4 ingot into the furnace and heat to 1050-1150℃

Forge the ingot, forging temperature should be not less than 850℃

Cooling in the air or in the furnace after forged

7: Heat treatment

Soft annealed:

Heat 51CrV4 steel to 820-850℃ in the furnace

Soak at this temperature in the furnace

Cooling in the furnace

Normalized:

Heat 51CrV4 steel to 860-890℃ in the furnace

Soak at this temperature in the furnace

Cooling in the air

Quenching and tempering:

Heat 51CrV4 steel to 820-870℃ in the furnace

Soak at this temperature in the furnace

Quench in oil

Temper steel at 540-680℃ in the furnace

Take out of 51CrV4 steel from furnace and cool in the air.

Remark: The conditions given above are for guidance, at the temperatures at the lower end of the range are generally applicable to hardening in water and those at the upper end for hardening in oil.

8: Weldability

51CrV4 steel has very poor weldability due to its high carbon content, typically ranging from 0.47% to 0.55%. Since weldability decreases significantly with increasing carbon content, steels with carbon levels well above 0.25% are highly prone to cracking. The addition of alloying elements like chromium and vanadium further increases hardenability, promoting the formation of extremely hard and brittle martensite in the Heat-Affected Zone (HAZ), which greatly elevates the risk of cold cracking. Therefore, welding is generally not recommended for this grade. If welding is absolutely necessary, it must be performed under strictly controlled procedures, including pre-heating (typically 250-400°C), post-heating, and subsequent stress-relief annealing.

9:Application

51CrV4 is a widely used, high-performance spring steel, highly valued for its excellent fatigue strength, high elasticity, and good toughness. Its main applications and uses are as follows:

1. Automotive Industry

1) Suspension springs: coil springs, torsion bar springs, etc.

2) Valve springs: valve springs within engines

3) Clutch springs: diaphragm springs, coil springs

4) Stabilizer bars

5) Brake system springs

2. Machinery Manufacturing and Industrial Equipment

1) Heavy Machinery Springs: Used in shock absorption and energy storage devices for various industrial machinery, hydraulic equipment, and agricultural machinery. 2) Mold Springs: Rectangular springs used in plastic injection molds, stamping dies, and other applications.

3) High-Performance Washers

3. Railway Industry

1) Railway Vehicle Suspension Springs: Used in bogie suspension systems for locomotives, passenger cars, and freight cars.

2) Buffer Springs: Springs used in coupler buffers.

4. Other High-Stress Tools and Components

1) High-Performance Wrenches: Especially those requiring high torque and explosion-proof features (such as torque wrenches).

2) Blades: Used in the manufacture of specialized blades requiring high toughness and elasticity (such as hunting and survival knives).

3) Shock Absorber Components: In addition to springs, also used in the manufacture of other shock-absorbing components requiring high fatigue strength.

51CrV4 / 1.8159 is a widely used spring steel belonging to the European standard EN 10083-3 and EN 10250-3. It is primarily employed in the manufacturing of high-stress springs and components for the automotive, railway, and machinery industries. Consequently, it has equivalent grades in various international standards, such as AISI 6150 from the American standard ASTM A29, SUP10 from the Japanese standard JIS G4801, 50CrVA from the Chinese standard GB/T 1222, and 735A50 from the British standard BS 970.

51CrV4 is a Cr-V steel series, characterized by a carbon content of 0.47-0.55%. After oil quenching and tempering, it achieves an excellent combination of high fatigue strength, good toughness, and outstanding elastic properties, making it particularly suitable for applications requiring high stress resistance and durability.

1: Steel equivalent

Country | China | Japan | USA | Europe | British |

Standard | GB/T 1222 | JIS G4801 | ASTM A29 | EN10083-3 | BS 970 |

Grade | 50CrVA | SUP10 | 6150 | 51CrV4/1.8159 | 735A50 |

2: Chemical composition

Grade | C | Si | Mn | P | S | Cr | V |

| 50CrVA | 0.46-0.54 | 0.17-0.37 | 0.50-0.80 | 0.025Max | 0.025Max | 0.8-1.1 | 0.1-0.2 |

| SUP10 | 0.47-0.55 | 0.15-0.35 | 0.65-0.95 | 0.030Max | 0.030Max | 0.8-1.1 | 0.15-0.25 |

| 6150 | 0.48-0.53 | 0.15-0.35 | 0.70-0.90 | 0.035Max | 0.040Max | 0.8-1.1 | 0.15Min |

| 51CrV4/1.8159 | 0.47-0.55 | 0.40Max | 0.70-1.10 | 0.025Max | 0.025Max | 0.9-1.2 | 0.10-0.25 |

3: Mechanical properties .

Mechanical properties for 51CrV4 quenching and tempering alloy steel.

Size range | Tensile strength | Yield strength | Alongation | Area of reduction | Impact value At RT/J |

d≤16 t≤8 | 1100-1300Mpa | 900Mpa Min | 9% Min | 40% Min | / |

16<d≤40 8<t≤20 | 1000-1200Mpa | 800Mpa Min | 10% Min | 45% Min | 30J Min |

| 40<d≤100 20<t≤60 | 900-1100Mpa | 700Mpa Min | 12% Min | 50% Min | 30J Min |

| 100<d≤160 60<t≤100 | 850-1000Mpa | 650Mpa Min | 13% Min | 50% Min | 30J Min |

| 160<d≤250 100<t≤160 | 800-950Mpa | 600Mpa Min | 13% Min | 50% Min | 30J Min |

Sampling and preparation of test pieces for 51CrV4 quenching and tempering steel.

1): According to EN10083-1, all samples shall be taken at a distance of 12.5mm below the heat treated surface

2): As stipulated in the contract between buyer and seller.

Mechanical properties for 51CrV4 open die forgings steel according to EN10250-3

Size range | Tensile strength | Yield strength | Alongation | Impact value at RT/J | ||

L | Tr | L | Tr | |||

d≤160 | 800Mpa Min | 600Mpa Min | 13% Min | 9% Min | 30J Min | 16J Min |

Remark: L= Longitudinal Tr = Transverse

Sampling and preparation of test pieces for steel forging.

1: According to EN10250-1, all samples shall be taken at a distance of 4/T below the heat treated surface (with a minimum of 20mm and a maximum of 80mm), and t/2 from the end (where t is the equivalent thickness of the thickness of the ruling section of the forging at the time of heat treatment.

2: As stipulated in the contract between buyer and seller.

4: Surface hardness and hardenability.

Heat Treatment | Hardness |

Soft annealed (+A) | HB248Max |

Quenched and tempred (+QT) | HRC28-32(Common Range) |

Where the steel is ordered by using the symbols for normal (+H) or restricted (+HL, +HH) hardenability requirements, the hardenability values should apply below:

Distance in mm from quenched end | ||||||||||||||||

Distance | 1.5 | 3 | 5 | 7 | 9 | 11 | 13 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | |

Hardness In HRC + H | max | 65 | 65 | 64 | 64 | 63 | 63 | 63 | 62 | 62 | 62 | 61 | 60 | 60 | 59 | 58 |

min | 57 | 56 | 56 | 55 | 53 | 52 | 50 | 48 | 44 | 41 | 37 | 35 | 34 | 33 | 32 | |

Hardness In HRC + HH | max | 65 | 65 | 64 | 64 | 63 | 63 | 63 | 62 | 62 | 62 | 61 | 60 | 60 | 59 | 58 |

min | 60 | 59 | 59 | 58 | 56 | 56 | 54 | 53 | 50 | 48 | 45 | 43 | 43 | 42 | 41 | |

Hardness In HRC + HL | max | 62 | 62 | 61 | 61 | 60 | 59 | 59 | 57 | 56 | 55 | 53 | 52 | 51 | 50 | 49 |

min | 57 | 56 | 56 | 55 | 53 | 52 | 50 | 48 | 44 | 41 | 37 | 35 | 34 | 33 | 32 | |

Scatter bands for the Rockwell - C hardness in the end quench hardenability test.

5: Supply size & Tolerance & Stock size

Product type | Size range | Length |

Cold drawn bar | Φ3-Φ80mm | 6000-9000mm |

Hot rolled bar | Φ16-Φ310mm | 6000-9000mm |

Hot forged bar | Φ100-Φ1200mm | 3000-5800mm |

Hot rolled plate/sheet | T:3-200mm; W:1500-2500mm | 2000-5800mm |

Hot Forged block | T: 80-800mm; W: 100-2500mm | 2000-5800mm |

Surface Finish | Turned | Milled | Grinding(Best) | Polished(Best) | Peeled(Best) | Black Forged | Black Rolled |

Tolerance | +0/+3mm | +0/+3mm | +0/+0.05mm | +0/+0.05mm | +0/+0.1mm | +0/+5mm | +0/+1mm |

Straighness | 1mm/1000mm max. | 3mm/1000mm max. | |||||

Qilu steel stock hot rolled bar and forged bars more than ten thousands tons every month, below our our stock size.

1): Stock diameter for hot rolled bar

16 | 18 | 20 | 22 | 24 | 25 | 26 | 27 | 28 | 30 | 31 | 32 | 33 | 35 | 36 |

38 | 39 | 40 | 42 | 45 | 46 | 48 | 50 | 52 | 55 | 56 | 58 | 60 | 62 | 63 |

65 | 68 | 70 | 72 | 75 | 78 | 80 | 82 | 83 | 85 | 87 | 90 | 95 | 100 | 105 |

110 | 115 | 120 | 125 | 130 | 135 | 140 | 145 | 150 | 155 | 160 | 170 | 180 | 190 | 200 |

210 | 220 | 230 | 240 | 250 | 260 | 270 | 280 | 290 | 300 | 310 |

2) : Stock diameter for hot forged bar

310 | 320 | 330 | 340 | 350 | 360 | 370 | 380 | 390 | 400 |

410 | 420 | 430 | 440 | 450 | 460 | 470 | 480 | 490 | 500 |

510 | 520 | 530 | 540 | 550 |

Since the stocks change everyday, if you want to know our stock available information, please contact our salesman.

6:Forging processing

Put the 51CrV4 ingot into the furnace and heat to 1050-1150℃

Forge the ingot, forging temperature should be not less than 850℃

Cooling in the air or in the furnace after forged

7: Heat treatment

Soft annealed:

Heat 51CrV4 steel to 820-850℃ in the furnace

Soak at this temperature in the furnace

Cooling in the furnace

Normalized:

Heat 51CrV4 steel to 860-890℃ in the furnace

Soak at this temperature in the furnace

Cooling in the air

Quenching and tempering:

Heat 51CrV4 steel to 820-870℃ in the furnace

Soak at this temperature in the furnace

Quench in oil

Temper steel at 540-680℃ in the furnace

Take out of 51CrV4 steel from furnace and cool in the air.

Remark: The conditions given above are for guidance, at the temperatures at the lower end of the range are generally applicable to hardening in water and those at the upper end for hardening in oil.

8: Weldability

51CrV4 steel has very poor weldability due to its high carbon content, typically ranging from 0.47% to 0.55%. Since weldability decreases significantly with increasing carbon content, steels with carbon levels well above 0.25% are highly prone to cracking. The addition of alloying elements like chromium and vanadium further increases hardenability, promoting the formation of extremely hard and brittle martensite in the Heat-Affected Zone (HAZ), which greatly elevates the risk of cold cracking. Therefore, welding is generally not recommended for this grade. If welding is absolutely necessary, it must be performed under strictly controlled procedures, including pre-heating (typically 250-400°C), post-heating, and subsequent stress-relief annealing.

9:Application

51CrV4 is a widely used, high-performance spring steel, highly valued for its excellent fatigue strength, high elasticity, and good toughness. Its main applications and uses are as follows:

1. Automotive Industry

1) Suspension springs: coil springs, torsion bar springs, etc.

2) Valve springs: valve springs within engines

3) Clutch springs: diaphragm springs, coil springs

4) Stabilizer bars

5) Brake system springs

2. Machinery Manufacturing and Industrial Equipment

1) Heavy Machinery Springs: Used in shock absorption and energy storage devices for various industrial machinery, hydraulic equipment, and agricultural machinery. 2) Mold Springs: Rectangular springs used in plastic injection molds, stamping dies, and other applications.

3) High-Performance Washers

3. Railway Industry

1) Railway Vehicle Suspension Springs: Used in bogie suspension systems for locomotives, passenger cars, and freight cars.

2) Buffer Springs: Springs used in coupler buffers.

4. Other High-Stress Tools and Components

1) High-Performance Wrenches: Especially those requiring high torque and explosion-proof features (such as torque wrenches).

2) Blades: Used in the manufacture of specialized blades requiring high toughness and elasticity (such as hunting and survival knives).

3) Shock Absorber Components: In addition to springs, also used in the manufacture of other shock-absorbing components requiring high fatigue strength.

content is empty!