English

T: +86-0731-85185770

E: enquiry@qilumetal.com

E: enquiry@qilumetal.com

No. 18 Xiangfu Middle Road,Yuhua District, Changsha City

Views: 0 Author: Site Editor Publish Time: 2025-10-23 Origin: Site

You use spring steel often, even if you do not know it. Think about the strong springs in your car. Or think about the sharp blade in your garden shears. Spring steel is special because it bends and goes back to its shape. This makes it great for parts that get used a lot. Its strength and flexibility help engineers make good products. Many industries need spring steel for important parts. These include automotive, aerospace, construction, and agriculture.

Industry | Description |

|---|---|

Automotive | Uses spring steel for car springs and engine parts. |

Aerospace | Needs spring steel for parts in tough conditions. |

Construction | Uses spring steel to make buildings stronger. |

Agriculture | Needs spring steel for tools that last and work well. |

Spring steel helps build machines, tools, and buildings you see every day.

Spring steel is very strong and bends easily. It goes back to its shape after bending. This makes it great for car springs and tools.

Many industries use spring steel. These include cars, planes, and building work. They need spring steel because it lasts long and works well in hard jobs.

Heat treatment makes spring steel better. It helps spring steel handle stress many times without breaking.

Picking the right type of spring steel is important. It helps tools and machines last longer and work well.

Spring steel has special features like high yield strength and toughness. These make it a favorite for engineers in many uses.

You see spring steel in cars all the time. Car makers use it in suspension systems. It helps absorb bumps and rough roads. Spring steel bends but goes back to its shape. This keeps your ride smooth and comfy. Spring steel is very strong and does not break easily. Springs made from it press down to take in shocks. This cuts down on shaking and makes cars safer. When you turn or stop, these springs spread weight to all wheels. This helps your car grip the road and turn better. Spring steel does not wear out fast. That is why it is used in coil springs and stabilizer bars.

Did you know? More cars mean more need for spring steel wire. The auto industry uses lots of strong springs and parts.

Spring steel is important in airplanes. You find it in parts like ailerons and wing flaps. These must move well and last in hard conditions. Chrome silicon spring steel is used for airplane springs. Engineers make special springs to fit small spaces. This helps make planes lighter. Lighter planes are better. New alloys make springs work better and last longer. These springs can take high heat and do not rust. This keeps planes safe and parts working, even in tough places.

Factories need spring steel for many moving parts. You see it in springs, load parts, and couplings. Spring steel is strong and can hold heavy things. It bends but goes back to its shape. This keeps machines working and stops them from breaking. Many machines use spring steel in gears, clutches, and valves. These parts must move fast and work well. They need strong materials for all the motion.

You use spring steel tools and blades every day. This material makes tools strong and able to cut or bend. Spring steel helps tools stay sharp and not break. It lasts a long time, even with lots of use. Here are some examples:

Tool/Blade Type | Description |

|---|---|

Piano Wire | Used in musical instruments for tension. |

Spring Clamps | Used to hold objects together with tension. |

Swords | Used for training and combat purposes. |

Knives | Commonly made for various cutting tasks. |

Machetes | Used for cutting through dense vegetation. |

Fish Tape | A tool for fishing wires through walls. |

Binder Clips | Used to hold sheets of paper together. |

Spring steel tools help you do hard jobs. You can cut, clamp, or hold things with them. These tools stay strong and work well.

Tip: Spring steel tools keep their shape and sharpness for a long time. This means you do not have to buy new ones often.

You find spring steel in many shapes. Each one has a special job in engineering and life.

Product Category |

|---|

Flat Bars |

Round Bars |

Sheets & Strips |

Wires |

Flat bars and round bars are used in buildings and machines. Sheets and strips are used for shims and washers. Wires are in springs, cables, and musical instruments. Spring steel is strong, bends well, and lasts long. It is better than many other materials. It does not lose its shape after bending. This is why engineers pick it for parts that must last.

Spring steel is used more as technology gets better. New ways to treat it and new alloys make it even stronger and more useful.

Spring steel stands out in engineering because of its unique properties. You can see how these mechanical properties make it the top choice for parts that need strength, flexibility, and long life. Let’s look at what makes spring steel so special.

You need high yield strength when you want a part to bend but not break. Spring steel gets this strength from its high carbon content and special heat treatment. These steps give it the ability to handle heavy loads and return to its original shape. In engineering, you often see spring steel used in places where parts must flex again and again without failing.

Here is a table showing the minimum tensile strength for different types of spring steel:

Material | Minimum Tensile Strength (psi) |

|---|---|

Music Wire ASTM A 228 | 230-3999 |

Hard Drawn ASTM A 277 | CLI 147-283 CLII 171-324 |

High Tensile Hard Drawn ASTM A 679 | 238-350 |

Oil Tempered ASTM A 229 | CLI 165-293 CLII 191-324 |

Carbon Valve ASTM A 230 | 215-240 |

High yield strength means you can use spring steel in dynamic environments. It will flex and compress many times without cracking. This property is key for springs, car parts, and tools that face repeated stress.

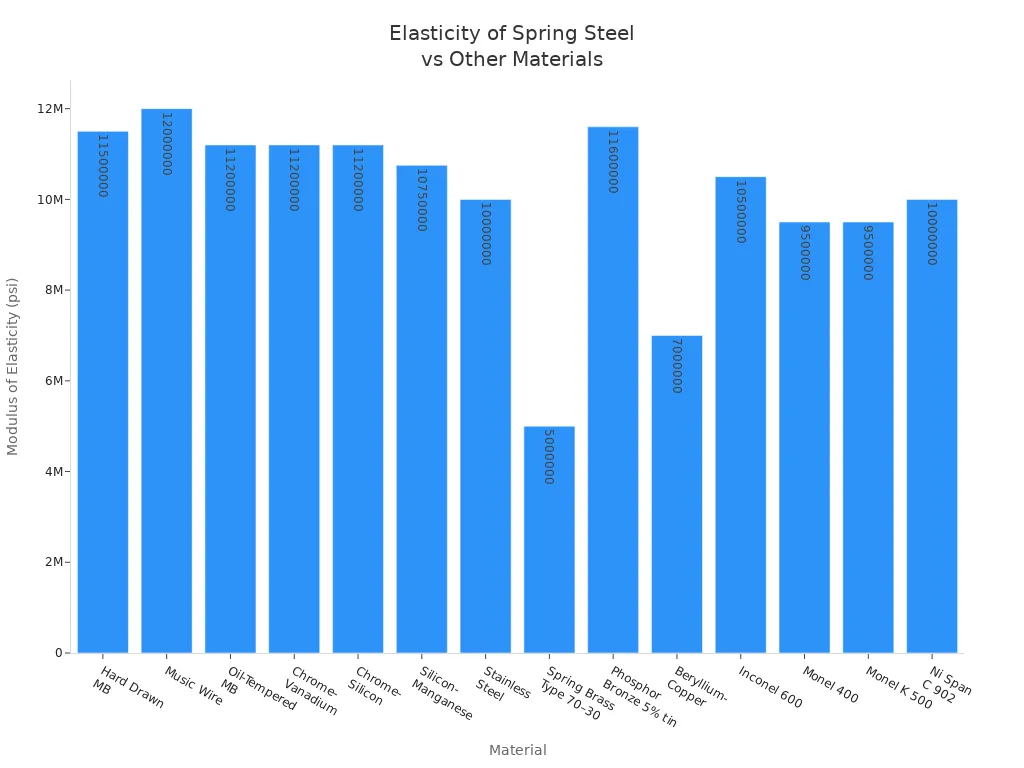

Elasticity lets spring steel stretch and snap back to its shape. This property comes from the way the atoms are arranged and the careful heat treatment process. You can see how important elasticity is when you use a spring or a blade. The material absorbs force and then returns to its starting point.

Here is a chart comparing the modulus of elasticity for spring steel and other materials:

Spring steel’s resilience means it can handle repeated bending and stretching. This gives it a long fatigue life. You can trust it in machines that move all day, every day.

Hardness is another key property. After heat treatment, spring steel can reach a Rockwell C hardness of Rc45. This level of hardness gives you toughness, resilience, and high fatigue strength. The dense structure from heat treatment helps the surface resist wear and tear.

Hardness (Rockwell C) | Characteristics |

|---|---|

Rc45 | Toughness, resilience, high fatigue strength |

You get durability from the high carbon content and the way spring steel is made. High-carbon spring steels last longer and stay strong under stress. Oil-tempered and chrome-silicon types resist shock and fatigue. You can use them in tough jobs where other materials might fail.

High-carbon spring steels have more carbon, which boosts strength and durability.

Oil-tempered steel keeps its strength at high temperatures.

Chrome-silicon spring steel resists shock and repeated loading.

You can see why engineers pick spring steel for parts that must last and perform under pressure. Its mechanical properties make it a reliable choice for many industries.

When you look at spring steel, you find many different grades. Each grade has a special use in engineering and manufacturing. You choose the right grade based on what you need the part to do. Some grades work better for tools, while others fit best in cars or airplanes.

Here are some of the most widely used spring steel grades:

AISI 1074/1075: You see these in agricultural tools and cutting tools.

AISI 1095: This grade is common in clock springs and knives.

SAE 5160: You find this in automotive suspension systems.

AISI 6150: Aircraft landing gear often uses this grade.

AISI 9260: Leaf springs and torsion bars use this type.

17-7PH Stainless Steel: Aerospace and medical tools rely on this grade.

301 Stainless Steel: Coil springs and metal stampings use this.

302 Stainless Steel: You see this in electronic connectors and springs for harsh environments.

The chemical makeup of each grade changes how it works. For example, high silicon or chromium can make spring steel stronger or more flexible. Here is a table that shows how different elements affect the properties of some grades:

Spring Steel Grade | Key Elements | Mechanical Properties Impact |

|---|---|---|

55CrSi | High Si, Cr | Improved fatigue resistance, yield strength |

50CrVA | Vanadium | Enhanced strength, toughness, hardenability |

30W4Cr2VA | W, Cr, V | High strength, elasticity at elevated temperatures |

60Si2Mn | High Si | Increased hardenability, strength, and tempering resistance |

You need to pick the right grade for your project. The right choice helps your product last longer and work better.

The heat treatment process is a key step in manufacturing spring steel. This process changes the microstructure and makes the steel strong, flexible, and tough. You must follow each step carefully to get the best results.

Here are the main steps in the heat treatment process:

Normalizing: Heat the steel to about 870°C (1600°F) for 20 minutes, then let it cool in air.

Annealing: Heat to 677°C (1250°F) for two hours to soften the steel.

Hardening: Raise the temperature to 829–850°C (1544°F) for a short time, depending on thickness.

Quenching: Cool the steel quickly in oil to lock in hardness.

Tempering: Reheat the steel to reduce brittleness and improve toughness.

Each step in manufacturing changes the steel’s grain structure. For example, quenching and tempering increase strength and ductility. The right heat treatment gives you spring steel that can bend, stretch, and return to its shape many times. If you skip a step or use the wrong temperature, the steel may crack or wear out too soon.

Tip: Careful heat treatment during manufacturing helps you get the best performance from your chosen spring steel grades.

You find spring steel in many places today. It is strong, flexible, and lasts a long time. These qualities help make cars safer. They also help machines work better. Tools made with spring steel are reliable. Spring steel bends but goes back to its shape. This makes it useful for lots of things. People use spring steel for parts that need to last. These parts also need to work well under pressure.

New science will make spring steel even stronger.

High tensile spring steel helps design springs for hard jobs.

The aerospace field needs new spring steel for tough places.

Spring steel will be more important as technology improves.

Spring steel has more carbon and special heat treatment. You get a material that bends and returns to its shape. Regular steel may bend and stay bent. Spring steel works better for parts that need to flex many times.

Yes, you can use spring steel outdoors. Some types resist rust better than others. Stainless spring steel works best for wet or harsh weather. You should check the grade before using it outside.

You need special tools to cut or shape spring steel. Use a hacksaw, grinder, or heavy-duty shears. Always wear safety gear. Spring steel is hard and can snap if you bend it too much.

You get strong, flexible, and long-lasting tools with spring steel. It keeps its shape and sharp edge. This makes it perfect for saws, knives, and clamps. You do not need to replace these tools often.

Many spring steel grades handle high heat well. Oil-tempered and chrome-silicon types work best in hot places. Always check the grade’s temperature rating before you use it in a hot environment.