English

T: +86-0731-85185770

E: enquiry@qilumetal.com

E: enquiry@qilumetal.com

No. 18 Xiangfu Middle Road,Yuhua District, Changsha City

| Availability: | |

|---|---|

| Quantity: | |

6150

Qilu

DIN 51CrV4 (also designated as 1.8159 under European standards) is a high-performance, quenched and tempered spring steel renowned for its exceptional combination of fatigue strength, elasticity, and toughness. Compliant with EN 10083-3 and EN 10250-3, this Cr-V alloy steel is a staple in industries requiring durable, high-stress components. Consequently, it has equivalent grades in various international standards, such as AISI 6150 from the American standard ASTM A29, SUP10 from the Japanese standard JIS G4801, 50CrVA from the Chinese standard GB/T 1222, and 735A50 from the British standard BS 970.

With a carbon content ranging from 0.47% to 0.55%, EN 51CrV4 achieves optimal mechanical properties through oil quenching and tempering. This heat treatment process enhances its resistance to wear, fatigue, and deformation, making it the material of choice for critical components in automotive, railway, machinery, and high-stress tooling applications. Whether for suspension springs, industrial machinery parts, or precision tools, 51CrV4 steel delivers reliability and longevity in demanding operating conditions.

To simplify material selection for global projects, below is a comprehensive table of DIN 51CrV4 equivalent grade across key international standards:

Country | China | Japan | USA | Europe | British |

Standard | GB/T 1222 | JIS G4801 | ASTM A29 | EN10083-3 | BS 970 |

Grade | 50CrVA | SUP10 | 6150 | 51CrV4/1.8159 | 735A50 |

All equivalent grades share similar chemical compositions and mechanical properties, ensuring seamless substitution in cross-border manufacturing and maintenance projects.

The superior performance of DIN 51CrV4 and its equivalents stems from a precisely balanced chemical makeup, optimized for strength, toughness, and heat treatability. Below is the detailed composition:

Grade | C | Si | Mn | P | S | Cr | V |

| 50CrVA | 0.46-0.54 | 0.17-0.37 | 0.50-0.80 | 0.025Max | 0.025Max | 0.80-1.10 | 0.10-0.20 |

| SUP10 | 0.47-0.55 | 0.15-0.35 | 0.65-0.95 | 0.030Max | 0.030Max | 0.80-1.10 | 0.15-0.25 |

| 6150 | 0.48-0.53 | 0.15-0.35 | 0.70-0.90 | 0.035Max | 0.040Max | 0.80-1.10 | 0.15Min |

| 51CrV4/1.8159 | 0.47-0.55 | 0.40Max | 0.70-1.10 | 0.025Max | 0.025Max | 0.90-1.20 | 0.10-0.25 |

DIN 51CrV4 mechanical properties are tailored to meet the demands of high-stress environments, with variations based on product size (diameter/thickness) and heat treatment. Below are the core properties for quenched and tempered (QT) DIN 51CrV4:

Size range | Tensile strength | Yield strength | Alongation | Area of reduction | Impact value At RT/J |

d≤16 t≤8 | 1100-1300Mpa | 900Mpa Min | 9% Min | 40% Min | / |

16<d≤40 8<t≤20 | 1000-1200Mpa | 800Mpa Min | 10% Min | 45% Min | 30J Min |

| 40<d≤100 20<t≤60 | 900-1100Mpa | 700Mpa Min | 12% Min | 50% Min | 30J Min |

| 100<d≤160 60<t≤100 | 850-1000Mpa | 650Mpa Min | 13% Min | 50% Min | 30J Min |

| 160<d≤250 100<t≤160 | 800-950Mpa | 600Mpa Min | 13% Min | 50% Min | 30J Min |

Size range | Tensile strength | Yield strength | Alongation | Impact value at RT/J | ||

L | Tr | L | Tr | |||

d≤160 | 800Mpa Min | 600Mpa Min | 13% Min | 9% Min | 30J Min | 16J Min |

Remark: L= Longitudinal Tr = Transverse

Quenched & Tempered Steel: Samples are taken 12.5mm below the heat-treated surface (per EN 10083-1) or as specified in the buyer-seller contract.

Open Die Forgings: Samples are taken at 4/T below the heat-treated surface (minimum 20mm, maximum 80mm) and t/2 from the end (T = equivalent thickness of the forging’s ruling section; per EN 10250-1) or as contractually agreed.

As stipulated in the contract between buyer and seller.

Heat Treatment | Hardness |

Soft annealed (+A) | HB248Max |

Quenched and tempred (+QT) | HRC28-32(Common Range) |

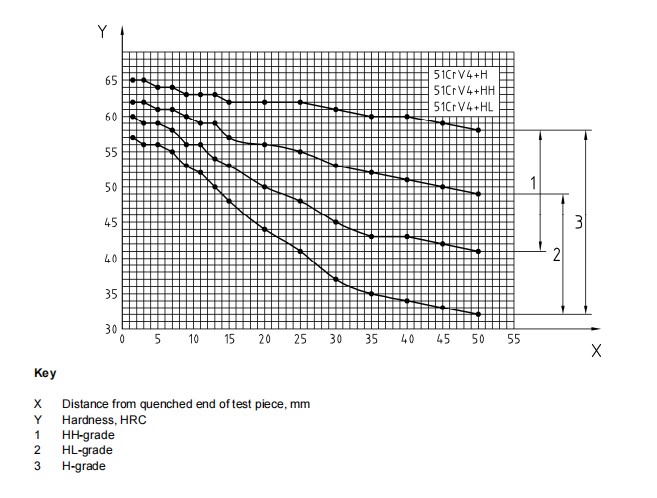

Hardenability values vary based on specified requirements (+H: Normal, +HH: High, +HL: Low Restricted). Below are the hardness ranges at different distances from the quenched end:

Distance in mm from quenched end | ||||||||||||||||

Distance | 1.5 | 3 | 5 | 7 | 9 | 11 | 13 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | |

Hardness In HRC + H | max | 65 | 65 | 64 | 64 | 63 | 63 | 63 | 62 | 62 | 62 | 61 | 60 | 60 | 59 | 58 |

min | 57 | 56 | 56 | 55 | 53 | 52 | 50 | 48 | 44 | 41 | 37 | 35 | 34 | 33 | 32 | |

Hardness In HRC + HH | max | 65 | 65 | 64 | 64 | 63 | 63 | 63 | 62 | 62 | 62 | 61 | 60 | 60 | 59 | 58 |

min | 60 | 59 | 59 | 58 | 56 | 56 | 54 | 53 | 50 | 48 | 45 | 43 | 43 | 42 | 41 | |

Hardness In HRC + HL | max | 62 | 62 | 61 | 61 | 60 | 59 | 59 | 57 | 56 | 55 | 53 | 52 | 51 | 50 | 49 |

min | 57 | 56 | 56 | 55 | 53 | 52 | 50 | 48 | 44 | 41 | 37 | 35 | 34 | 33 | 32 | |

Hardenability scatter bands ensure consistency across batches, making DIN 51CrV4 suitable for components requiring uniform performance.

Scatter bands for the Rockwell - C hardness in the end quench hardenability test.

We offer DIN 51CrV4 in a wide range of product forms to meet diverse application needs, with strict adherence to dimensional tolerances and surface finish standards.

Product type | Size range | Length |

Cold drawn bar | Φ3-Φ80mm | 6000-9000mm |

Hot rolled bar | Φ16-Φ310mm | 6000-9000mm |

Hot forged bar | Φ100-Φ1200mm | 3000-5800mm |

Hot rolled plate/sheet | T:3-200mm; W:1500-2500mm | 2000-5800mm |

Hot Forged block | T: 80-800mm; W: 100-2500mm | 2000-5800mm |

Surface Finish | Turned | Milled | Grinding(Best) | Polished(Best) | Peeled(Best) | Black Forged | Black Rolled |

Tolerance | +0/+3mm | +0/+3mm | +0/+0.05mm | +0/+0.05mm | +0/+0.1mm | +0/+5mm | +0/+1mm |

Straighness | 1mm/1000mm max. | 3mm/1000mm max. | |||||

Qilu steel stock hot rolled bar and forged bars more than ten thousands tons every month, below our our stock size.

Hot Rolled Bar Stock Diameters (mm): 16, 18, 20, 22, 24, 25, 26, 27, 28, 30, 31, 32, 33, 35, 36, 38, 39, 40, 42, 45, 46, 48, 50, 52, 55, 56, 58, 60, 62, 63, 65, 68, 70, 72, 75, 78, 80, 82, 83, 85, 87, 90, 95, 100, 105, 110, 115, 120, 125, 130, 135, 140, 145, 150, 155, 160, 170, 180, 190, 200, 210, 220, 230, 240, 250, 260, 270, 280, 290, 300, 310

Hot Forged Bar Stock Diameters (mm): 310, 320, 330, 340, 350, 360, 370, 380, 390, 400, 410, 420, 430, 440, 450, 460, 470, 480, 490, 500, 510, 520, 530, 540, 550

Stock availability changes daily. For real-time inventory checks or custom size requests, please contact our sales team.

Heating: DIN 51CrV4 ingots are heated to 1050-1150℃ in a controlled atmosphere furnace to ensure uniform temperature distribution.

Forging: Forging is performed at a minimum temperature of 850℃ to maintain grain refinement and avoid brittleness.

Cooling: After forging, components are cooled in air or furnace-cooled to prevent thermal stress and deformation.

Proper heat treatment is critical to unlocking DIN 51CrV4 full performance potential. Below are recommended processes:

Soft Annealing: Heat to 820-850℃ → Soak at temperature → Furnace cool

Normalizing: Heat to 860-890℃ → Soak at temperature → Air cool

Quenching & Tempering (+QT): Heat to 820-870℃ → Soak → Oil quench → Temper at 540-680℃ → Air cool

Note: Temperature ranges are guidelines. Lower-end temperatures are suitable for water quenching, while upper-end temperatures are ideal for oil quenching. Custom heat treatment can be arranged based on specific application requirements.

DIN 51CrV4 has poor weldability due to its high carbon content (0.47-0.55%) and alloying elements (Cr, V). Key considerations:

High carbon content (>0.25%) increases the risk of cracking during welding.

Chromium and vanadium enhance hardenability, leading to brittle martensite formation in the Heat-Affected Zone (HAZ), increasing cold cracking risk.

Pre-heat the base material to 250-400℃ to reduce thermal gradients.

Use low-hydrogen welding consumables to minimize hydrogen-induced cracking.

Post-weld heat treatment (PWHT) and stress-relief annealing to reduce residual stresses.

Limit weld size and avoid welding thick sections where possible.

In most cases, welding is not recommended. For assembled components, mechanical fastening (bolting, riveting) is preferred.

DIN 51CrV4 exceptional fatigue strength, elasticity, and toughness make it indispensable in high-stress industries. Below are key applications:

1. Automotive Industry

Suspension Systems: Coil springs, torsion bar springs, and stabilizer bars (ensure ride comfort and handling).

Engine Components: Valve springs (withstand high temperatures and cyclic loads).

Transmission & Brakes: Clutch diaphragm springs, coil springs, and brake system springs (reliable force transmission).

2. Machinery & Industrial Equipment

Heavy Machinery: Shock absorption springs for hydraulic equipment, agricultural machinery, and construction tools.

Mold & Tooling: Rectangular mold springs for plastic injection molds and stamping dies.

Precision Components: High-performance washers and fasteners requiring consistent elasticity.

3. Railway Industry

Suspension Systems: Bogie suspension springs for locomotives, passenger cars, and freight trains (absorb track vibrations).

Coupler Buffers: Buffer springs for railway car couplers (mitigate impact forces).

4. High-Stress Tools & Specialty Components

Tools: Torque wrenches and explosion-proof wrenches (high torque resistance).

Blades: Hunting/survival knives (balance of toughness and edge retention).

Shock Absorbers: Critical components in industrial and automotive shock absorber systems (fatigue resistance).

A1: DIN 51CrV4 (1.8159) and AISI 6150 are equivalent grades with nearly identical chemical compositions and mechanical properties. The main difference is their respective standards: DIN 51CrV4 follows European EN standards, while AISI 6150 adheres to American ASTM standards. They are fully interchangeable in most applications.

A2: Yes. DIN 51CrV4’s vanadium content enhances heat resistance, making it suitable for applications with operating temperatures up to 300-350℃ (e.g., engine valve springs). For temperatures exceeding 350℃, consult our team for custom heat treatment or alloy modifications.

A3: Store in a dry, well-ventilated area away from moisture and corrosive substances. For long-term storage, apply anti-corrosion oil or wrap in moisture-resistant packaging. Hot rolled/forged products with a black oxide finish offer moderate corrosion resistance but should still be protected in humid environments.

A4: Soft-annealed DIN 51CrV4 (HB ≤248) can be cold formed (e.g., bending, coiling) with proper tooling. Cold forming should be performed before quenching and tempering, as the QT state is too hard for most cold working processes.

A5: Yes. We offer custom quenching, tempering, annealing, and stress-relief treatments to meet specific hardness, strength, or toughness requirements. Contact our engineering team with your application details for tailored solutions.

Strict Quality Control: Each batch undergoes chemical composition analysis, mechanical testing, and hardness verification.

Versatile Supply: Wide range of sizes, finishes, and custom processes to fit unique applications.

Expert Support: Our engineering team provides technical guidance on material selection, heat treatment, and application optimization.

Reliable Stock: Tens of thousands of tons in monthly stock ensure quick delivery for urgent projects.

For inquiries, custom quotes, or technical support, contact our sales team today. We are committed to delivering high-quality DIN 51CrV4 solutions tailored to your industry needs.

DIN 51CrV4 (also designated as 1.8159 under European standards) is a high-performance, quenched and tempered spring steel renowned for its exceptional combination of fatigue strength, elasticity, and toughness. Compliant with EN 10083-3 and EN 10250-3, this Cr-V alloy steel is a staple in industries requiring durable, high-stress components. Consequently, it has equivalent grades in various international standards, such as AISI 6150 from the American standard ASTM A29, SUP10 from the Japanese standard JIS G4801, 50CrVA from the Chinese standard GB/T 1222, and 735A50 from the British standard BS 970.

With a carbon content ranging from 0.47% to 0.55%, EN 51CrV4 achieves optimal mechanical properties through oil quenching and tempering. This heat treatment process enhances its resistance to wear, fatigue, and deformation, making it the material of choice for critical components in automotive, railway, machinery, and high-stress tooling applications. Whether for suspension springs, industrial machinery parts, or precision tools, 51CrV4 steel delivers reliability and longevity in demanding operating conditions.

To simplify material selection for global projects, below is a comprehensive table of DIN 51CrV4 equivalent grade across key international standards:

Country | China | Japan | USA | Europe | British |

Standard | GB/T 1222 | JIS G4801 | ASTM A29 | EN10083-3 | BS 970 |

Grade | 50CrVA | SUP10 | 6150 | 51CrV4/1.8159 | 735A50 |

All equivalent grades share similar chemical compositions and mechanical properties, ensuring seamless substitution in cross-border manufacturing and maintenance projects.

The superior performance of DIN 51CrV4 and its equivalents stems from a precisely balanced chemical makeup, optimized for strength, toughness, and heat treatability. Below is the detailed composition:

Grade | C | Si | Mn | P | S | Cr | V |

| 50CrVA | 0.46-0.54 | 0.17-0.37 | 0.50-0.80 | 0.025Max | 0.025Max | 0.80-1.10 | 0.10-0.20 |

| SUP10 | 0.47-0.55 | 0.15-0.35 | 0.65-0.95 | 0.030Max | 0.030Max | 0.80-1.10 | 0.15-0.25 |

| 6150 | 0.48-0.53 | 0.15-0.35 | 0.70-0.90 | 0.035Max | 0.040Max | 0.80-1.10 | 0.15Min |

| 51CrV4/1.8159 | 0.47-0.55 | 0.40Max | 0.70-1.10 | 0.025Max | 0.025Max | 0.90-1.20 | 0.10-0.25 |

DIN 51CrV4 mechanical properties are tailored to meet the demands of high-stress environments, with variations based on product size (diameter/thickness) and heat treatment. Below are the core properties for quenched and tempered (QT) DIN 51CrV4:

Size range | Tensile strength | Yield strength | Alongation | Area of reduction | Impact value At RT/J |

d≤16 t≤8 | 1100-1300Mpa | 900Mpa Min | 9% Min | 40% Min | / |

16<d≤40 8<t≤20 | 1000-1200Mpa | 800Mpa Min | 10% Min | 45% Min | 30J Min |

| 40<d≤100 20<t≤60 | 900-1100Mpa | 700Mpa Min | 12% Min | 50% Min | 30J Min |

| 100<d≤160 60<t≤100 | 850-1000Mpa | 650Mpa Min | 13% Min | 50% Min | 30J Min |

| 160<d≤250 100<t≤160 | 800-950Mpa | 600Mpa Min | 13% Min | 50% Min | 30J Min |

Size range | Tensile strength | Yield strength | Alongation | Impact value at RT/J | ||

L | Tr | L | Tr | |||

d≤160 | 800Mpa Min | 600Mpa Min | 13% Min | 9% Min | 30J Min | 16J Min |

Remark: L= Longitudinal Tr = Transverse

Quenched & Tempered Steel: Samples are taken 12.5mm below the heat-treated surface (per EN 10083-1) or as specified in the buyer-seller contract.

Open Die Forgings: Samples are taken at 4/T below the heat-treated surface (minimum 20mm, maximum 80mm) and t/2 from the end (T = equivalent thickness of the forging’s ruling section; per EN 10250-1) or as contractually agreed.

As stipulated in the contract between buyer and seller.

Heat Treatment | Hardness |

Soft annealed (+A) | HB248Max |

Quenched and tempred (+QT) | HRC28-32(Common Range) |

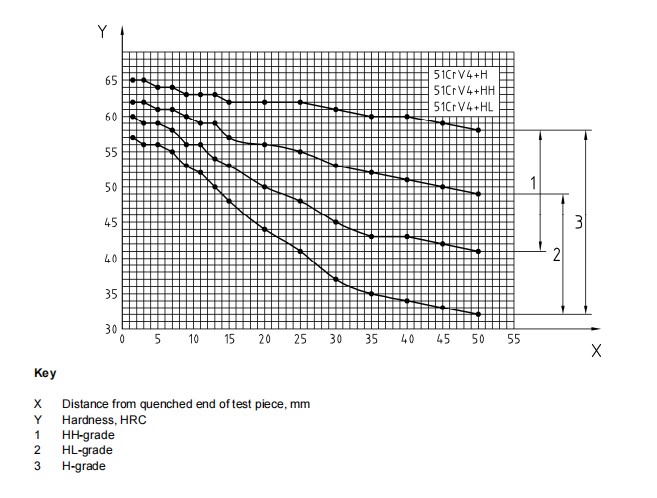

Hardenability values vary based on specified requirements (+H: Normal, +HH: High, +HL: Low Restricted). Below are the hardness ranges at different distances from the quenched end:

Distance in mm from quenched end | ||||||||||||||||

Distance | 1.5 | 3 | 5 | 7 | 9 | 11 | 13 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | |

Hardness In HRC + H | max | 65 | 65 | 64 | 64 | 63 | 63 | 63 | 62 | 62 | 62 | 61 | 60 | 60 | 59 | 58 |

min | 57 | 56 | 56 | 55 | 53 | 52 | 50 | 48 | 44 | 41 | 37 | 35 | 34 | 33 | 32 | |

Hardness In HRC + HH | max | 65 | 65 | 64 | 64 | 63 | 63 | 63 | 62 | 62 | 62 | 61 | 60 | 60 | 59 | 58 |

min | 60 | 59 | 59 | 58 | 56 | 56 | 54 | 53 | 50 | 48 | 45 | 43 | 43 | 42 | 41 | |

Hardness In HRC + HL | max | 62 | 62 | 61 | 61 | 60 | 59 | 59 | 57 | 56 | 55 | 53 | 52 | 51 | 50 | 49 |

min | 57 | 56 | 56 | 55 | 53 | 52 | 50 | 48 | 44 | 41 | 37 | 35 | 34 | 33 | 32 | |

Hardenability scatter bands ensure consistency across batches, making DIN 51CrV4 suitable for components requiring uniform performance.

Scatter bands for the Rockwell - C hardness in the end quench hardenability test.

We offer DIN 51CrV4 in a wide range of product forms to meet diverse application needs, with strict adherence to dimensional tolerances and surface finish standards.

Product type | Size range | Length |

Cold drawn bar | Φ3-Φ80mm | 6000-9000mm |

Hot rolled bar | Φ16-Φ310mm | 6000-9000mm |

Hot forged bar | Φ100-Φ1200mm | 3000-5800mm |

Hot rolled plate/sheet | T:3-200mm; W:1500-2500mm | 2000-5800mm |

Hot Forged block | T: 80-800mm; W: 100-2500mm | 2000-5800mm |

Surface Finish | Turned | Milled | Grinding(Best) | Polished(Best) | Peeled(Best) | Black Forged | Black Rolled |

Tolerance | +0/+3mm | +0/+3mm | +0/+0.05mm | +0/+0.05mm | +0/+0.1mm | +0/+5mm | +0/+1mm |

Straighness | 1mm/1000mm max. | 3mm/1000mm max. | |||||

Qilu steel stock hot rolled bar and forged bars more than ten thousands tons every month, below our our stock size.

Hot Rolled Bar Stock Diameters (mm): 16, 18, 20, 22, 24, 25, 26, 27, 28, 30, 31, 32, 33, 35, 36, 38, 39, 40, 42, 45, 46, 48, 50, 52, 55, 56, 58, 60, 62, 63, 65, 68, 70, 72, 75, 78, 80, 82, 83, 85, 87, 90, 95, 100, 105, 110, 115, 120, 125, 130, 135, 140, 145, 150, 155, 160, 170, 180, 190, 200, 210, 220, 230, 240, 250, 260, 270, 280, 290, 300, 310

Hot Forged Bar Stock Diameters (mm): 310, 320, 330, 340, 350, 360, 370, 380, 390, 400, 410, 420, 430, 440, 450, 460, 470, 480, 490, 500, 510, 520, 530, 540, 550

Stock availability changes daily. For real-time inventory checks or custom size requests, please contact our sales team.

Heating: DIN 51CrV4 ingots are heated to 1050-1150℃ in a controlled atmosphere furnace to ensure uniform temperature distribution.

Forging: Forging is performed at a minimum temperature of 850℃ to maintain grain refinement and avoid brittleness.

Cooling: After forging, components are cooled in air or furnace-cooled to prevent thermal stress and deformation.

Proper heat treatment is critical to unlocking DIN 51CrV4 full performance potential. Below are recommended processes:

Soft Annealing: Heat to 820-850℃ → Soak at temperature → Furnace cool

Normalizing: Heat to 860-890℃ → Soak at temperature → Air cool

Quenching & Tempering (+QT): Heat to 820-870℃ → Soak → Oil quench → Temper at 540-680℃ → Air cool

Note: Temperature ranges are guidelines. Lower-end temperatures are suitable for water quenching, while upper-end temperatures are ideal for oil quenching. Custom heat treatment can be arranged based on specific application requirements.

DIN 51CrV4 has poor weldability due to its high carbon content (0.47-0.55%) and alloying elements (Cr, V). Key considerations:

High carbon content (>0.25%) increases the risk of cracking during welding.

Chromium and vanadium enhance hardenability, leading to brittle martensite formation in the Heat-Affected Zone (HAZ), increasing cold cracking risk.

Pre-heat the base material to 250-400℃ to reduce thermal gradients.

Use low-hydrogen welding consumables to minimize hydrogen-induced cracking.

Post-weld heat treatment (PWHT) and stress-relief annealing to reduce residual stresses.

Limit weld size and avoid welding thick sections where possible.

In most cases, welding is not recommended. For assembled components, mechanical fastening (bolting, riveting) is preferred.

DIN 51CrV4 exceptional fatigue strength, elasticity, and toughness make it indispensable in high-stress industries. Below are key applications:

1. Automotive Industry

Suspension Systems: Coil springs, torsion bar springs, and stabilizer bars (ensure ride comfort and handling).

Engine Components: Valve springs (withstand high temperatures and cyclic loads).

Transmission & Brakes: Clutch diaphragm springs, coil springs, and brake system springs (reliable force transmission).

2. Machinery & Industrial Equipment

Heavy Machinery: Shock absorption springs for hydraulic equipment, agricultural machinery, and construction tools.

Mold & Tooling: Rectangular mold springs for plastic injection molds and stamping dies.

Precision Components: High-performance washers and fasteners requiring consistent elasticity.

3. Railway Industry

Suspension Systems: Bogie suspension springs for locomotives, passenger cars, and freight trains (absorb track vibrations).

Coupler Buffers: Buffer springs for railway car couplers (mitigate impact forces).

4. High-Stress Tools & Specialty Components

Tools: Torque wrenches and explosion-proof wrenches (high torque resistance).

Blades: Hunting/survival knives (balance of toughness and edge retention).

Shock Absorbers: Critical components in industrial and automotive shock absorber systems (fatigue resistance).

A1: DIN 51CrV4 (1.8159) and AISI 6150 are equivalent grades with nearly identical chemical compositions and mechanical properties. The main difference is their respective standards: DIN 51CrV4 follows European EN standards, while AISI 6150 adheres to American ASTM standards. They are fully interchangeable in most applications.

A2: Yes. DIN 51CrV4’s vanadium content enhances heat resistance, making it suitable for applications with operating temperatures up to 300-350℃ (e.g., engine valve springs). For temperatures exceeding 350℃, consult our team for custom heat treatment or alloy modifications.

A3: Store in a dry, well-ventilated area away from moisture and corrosive substances. For long-term storage, apply anti-corrosion oil or wrap in moisture-resistant packaging. Hot rolled/forged products with a black oxide finish offer moderate corrosion resistance but should still be protected in humid environments.

A4: Soft-annealed DIN 51CrV4 (HB ≤248) can be cold formed (e.g., bending, coiling) with proper tooling. Cold forming should be performed before quenching and tempering, as the QT state is too hard for most cold working processes.

A5: Yes. We offer custom quenching, tempering, annealing, and stress-relief treatments to meet specific hardness, strength, or toughness requirements. Contact our engineering team with your application details for tailored solutions.

Strict Quality Control: Each batch undergoes chemical composition analysis, mechanical testing, and hardness verification.

Versatile Supply: Wide range of sizes, finishes, and custom processes to fit unique applications.

Expert Support: Our engineering team provides technical guidance on material selection, heat treatment, and application optimization.

Reliable Stock: Tens of thousands of tons in monthly stock ensure quick delivery for urgent projects.

For inquiries, custom quotes, or technical support, contact our sales team today. We are committed to delivering high-quality DIN 51CrV4 solutions tailored to your industry needs.