English

T: +86-0731-85185770

E: enquiry@qilumetal.com

E: enquiry@qilumetal.com

No. 18 Xiangfu Middle Road,Yuhua District, Changsha City

Grade: C35 1.0501

Equivalent Steel: AISI 1035, GB 35#, BS 060A35, JIS S35C

C35 / 1.0501 medium carbon steel is defined by a precisely controlled chemical composition that ensures its reliable performance. Its primary characteristic is a carbon content ranging from 0.32% to 0.39%, which provides an optimal balance of strength, hardness, and toughness. The steel is alloyed with manganese (0.50%-0.80%) to enhance hardenability and strength. Silicon content is kept below 0.40% to maintain good castability and deoxidation during production.

| Availability: | |

|---|---|

| Quantity: | |

1035

Qilu

AISI 1035 / DIN C35 1.0501 / JIS S35C / BS 060A35 is a versatile medium carbon steel that stands out in the manufacturing industry for its balanced blend of strength, ductility, and machinability. Classified under international standards including American Standard ASTM 1035 (ASTM A20), Japanese Standard S35C (JIS G4051), Chinese Standard 35# (GB/T 699), and British Standard 060A35 (BS 970), this steel grade has become a go-to choice for engineers and manufacturers worldwide.

With a carbon content ranging from 0.32% to 0.39%, it strikes the perfect balance between the brittleness of high-carbon steels (such as AISI 1060) and the lower tensile strength of low-carbon steels (like AISI 1020). This unique composition allows it to retain excellent ductility while delivering sufficient strength to meet the demands of most engineering applications. Whether used in its as-rolled, normalized, or quenched and tempered state, this steel consistently delivers reliable performance, making it suitable for a wide range of industries, from mechanical manufacturing and automotive production to tool and mold making, architectural structures, and beyond.

Country | USA | Europe | China | British | Japan |

Standard | ASTM A29 | EN10083-2 | GB/T699 | BS970 | JIS G4051 |

Grade | 1035 | C35/1.0501 | 35# | 060A35 | S35C |

The chemical makeup of AISI 1035 / DIN C35 1.0501 / JIS S35C / BS 060A35 is tightly controlled to ensure uniform performance across every batch. Each element plays a critical role in shaping the steel’s properties:

Carbon (C): 0.32-0.39%: The primary strengthener, balancing hardness for load-bearing capacity and toughness to resist cracking under impact.

Manganese (Mn): 0.50-0.90%: Improves hardenability (helping the steel respond better to heat treatment) and enhances machinability by reducing friction between the steel and cutting tools.

Silicon (Si): ≤0.40% Max: Boosts strength during heat treatment without making the steel overly brittle, with strict limits to avoid compromising ductility.

Phosphorus (P) & Sulfur (S): ≤0.045% Max Each: Minimized to prevent brittleness and cracking, especially during welding or forging.

Trace Elements (Cr, Mo, Ni): ≤0.40% Max: Chromium (Cr), molybdenum (Mo), and nickel (Ni) are present in small amounts to enhance overall stability—for example, JIS S35C limits Cr to ≤0.20% to maintain its machinability.

Grade | C | Si | Mn | P | S | Cr | Mo | Ni |

1035 | 0.32-0.38 | / | 0.60-0.90 | 0.040Max | 0.050Max | / | / | / |

C35/1.0501 | 0.32-0.39 | 0.40Max | 0.50-0.80 | 0.045Max | 0.045Max | 0.40Max | 0.10Max | 0.40Max |

35# | 0.32-0.39 | 0.17-0.37 | 0.50-0.80 | 0.035Max | 0.035Max | 0.25Max | / | 0.30Max |

S35C | 0.32-0.38 | 0.15-0.35 | 0.60-0.90 | 0.030Max | 0.035Max | 0.20Max | / | / |

This well-balanced chemical composition ensures the steel behaves predictably during processing, whether undergoing annealing, normalizing, quenching and tempering, or other heat treatment processes, and delivers consistent performance in end-use applications.

The mechanical performance of AISI 1035 / DIN C35 1.0501 / JIS S35C / BS 060A35 varies by processing condition, allowing manufacturers to select the right state for their specific use case. Below is a detailed breakdown of its mechanical properties under different conditions:

Size range | Tensile strength | Yield strength | Alongation | Area of reduction | Impact value At RT/J |

d≤16 t≤8 | 630-780Mpa | 430Mpa Min | 17% Min | 40% Min | / |

16<d≤40 8<t≤20 | 600-750Mpa | 380Mpa Min | 19% Min | 45%Min | / |

Size range | Tensile strength | Yield strength | Alongation | Area of reduction | Impact value At RT/J |

d≤16 t≤16 | 550Mpa | 300Mpa Min | 18% Min | / | / |

16<d≤100 16<t≤100 | 520Mpa | 270Mpa Min | 19% Min | / | / |

100<d≤250 100<t≤250 | 500Mpa | 245Mpa Min | 19% Min | / | / |

Sampling and preparation of test pieces for C35 quenching and tempering steel.

1): According to EN10083-1, all samples shall be taken at a distance of 12.5mm below the heat treated surface

2): As stipulated in the contract between buyer and seller.

Mechanical properties for C35 open die forgings steel in the normalized and normalized and tempered conditions according to EN10250-2.

Mechanical properties for C35 open die forgings steel in the normalized or normalized and tempered conditions according to EN10250-2.

Size range | Tensile strength | Yield strength | Alongation | Impact value at RT/J | ||

L | Tr | L | Tr | |||

d≤100 | 520Mpa Min | 270Mpa Min | 19% Min | / | 30J Min | / |

100<d≤250 | 500Mpa Min | 245Mpa Min | 19% Min | 15% Min | 25J Min | 15J Min |

250<d≤500 | 480Mpa Min | 220Mpa Min | 19% Min | 15% Min | 20J Min | 12J Min |

500<d≤1000 | 470Mpa Min | 210Mpa Min | 18% Min | 14% Min | 17J Min | 12J Min |

Mechanical properties for C35 open die forgings steel in the quenched and tempered conditions according to EN10250-2.

Size range | Tensile strength | Yield strength | Alongation | Impact value at RT/J | ||

L | Tr | L | Tr | |||

d≤70 | 550Mpa Min | 320Mpa Min | 20% Min | / | 35J Min | / |

70<d≤160 | 490Mpa Min | 290Mpa Min | 22% Min | 15% Min | 31J Min | 20J Min |

160<d≤330 | 270Mpa Min | 270Mpa Min | 21% Min | 14% Min | 25J Min | 16J Min |

Remark: L= Longitudinal Tr = Transverse

Sampling and preparation of test pieces for steel forging.

1: According to EN10250-1, all samples shall be taken at a distance of 4/T below the heat treated surface (with a minimum of 20mm and a maximum of 80mm), and t/2 from the end (where t is the equivalent thickness of the thickness of the ruling section of the forging at the time of heat treatment.

2: As stipulated in the contract between buyer and seller.

These mechanical properties make the steel highly adaptable. In the normalized condition, it is ideal for low-to-medium stress parts like brackets, pins, and flanges. When quenched and tempered, it delivers enhanced strength and toughness, making it suitable for high-stress components such as gears, shafts, connecting rods, and drive shafts. Open die forgings, available in various sizes, offer excellent durability for heavy machinery parts like forged shafts and large structural components.

AISI 1035 / DIN C35 1.0501 / JIS S35C / BS 060A35 offers reliable hardenability, a key factor for parts requiring wear-resistant surfaces. The steel’s hardenability can be tailored to meet specific application requirements through different heat treatment processes:

Flame or Induction Hardening: Achieves a surface hardness of 48 HRC, ideal for parts like gear teeth and shaft journals that face repeated friction.

Soft Annealed (+A): Reduces hardness to 130-170 HBW, making the steel easy to machine into precision parts like jigs or mold bases.

Quenched & Tempered (+QT): Common hardness range is 28-32 HRC, balancing strength and toughness for load-bearing components.

Heat Treatment | Hardness |

Flame or Induction hardening | 48HRC |

Treated to improve shearability (+S) | 150-200HBW |

Soft annealed (+A) | 130-170HBW |

Quenched and tempred (+QT) | HRC28-32(Common Range) |

+HH14 (High Hardenability): At 1mm from the quenched end, hardness ranges from 48-58 HRC; at 4mm, it stays at 34-53 HRC, suitable for parts needing deep hardness penetration.

+HL14 (Low Hardenability): At 4mm from the quenched end, hardness is 24-43 HRC, ideal for parts where uniform hardness across the section is more important than deep penetration.

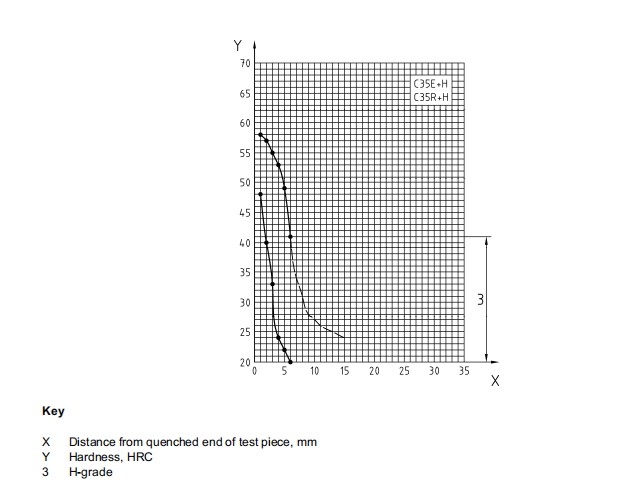

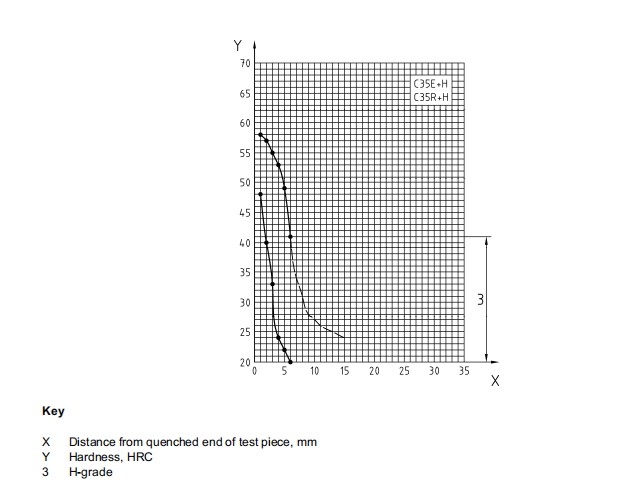

Where the steel is ordered by using the symbols for normal (+H) or restricted (+HL, +HH) hardenability requirements, the hardenability values should apply below:

Distance in mm from quenched end | ||||||||||||||

Distance | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 13 | 15 | |

Hardness In HRC + H | max | 58 | 57 | 55 | 53 | 49 | 41 | 34 | 31 | 28 | 27 | 26 | 25 | 24 |

min | 48 | 40 | 33 | 24 | 22 | 20 | / | / | / | / | / | / | / | |

Hardness In HRC + HH | +HH4 | / | / | / | 34-53 | / | / | / | / | / | / | / | / | / |

+HH14 | 51-58 | / | / | 34-53 | / | / | / | / | / | / | / | / | / | |

Hardness In HRC + HL | +HL4 | / | / | / | 24-43 | / | / | / | / | / | / | / | / | / |

+HL14 | 48-55 | / | / | 24-43 | / | / | / | / | / | / | / | / | / | |

The ability to adjust the steel hardenability and surface hardness makes it highly versatile, allowing it to meet the specific wear resistance and strength requirements of a wide range of applications.

Scatter bands for the Rockwell - C hardness in the end quench hardenability test.

Hunan Qilu Steel provides AISI 1035 / DIN C35 1.0501 / JIS S35C / BS 060A35 in a wide range of forms and sizes, with strict tolerances to meet diverse precision requirements. Our commitment to quality ensures that every product meets or exceeds international standards, providing our customers with reliable and consistent performance:

Cold Drawn Bar: Diameter Φ3-Φ80mm, length 6000-9000mm—perfect for small, precision parts like electronic pins or fasteners.

Hot Rolled Bar: Diameter Φ16-Φ300mm, length 6000-9000mm—cost-effective for medium-sized components like brackets or lever arms.

Hot Forged Bar: Diameter Φ100-Φ1200mm, length 3000-5800mm—ideal for heavy machinery parts like large shafts or forged blocks.

Hot Rolled Plate/Sheet: Thickness 3-200mm, width 1500-2500mm, length 2000-5800mm—versatile for structural applications like building supports or machine frames.

Product type | Size range | Length |

Cold drawn bar | Φ3-Φ80mm | 6000-9000mm |

Hot rolled bar | Φ16-Φ300mm | 6000-9000mm |

Hot forged bar | Φ100-Φ1200mm | 3000-5800mm |

Hot rolled plate/sheet | T:3-200mm; W:1500-2500mm | 2000-5800mm |

Hot Forged block | T: 80-800mm; W: 100-2500mm | 2000-5800mm |

Grinding or Polished Finish: Tolerance of +0/+0.05mm, the highest precision for critical parts like mold cores or precision shafts.

Peeled Finish: Tolerance of +0/+0.1mm, excellent for machined components where surface smoothness is key.

Hot Rolled or Black Forged Finish: Tolerance ranges from +0/+1mm (hot rolled) to +0/+5mm (black forged), cost-efficient for non-precision parts like rough structural brackets.

Straightness: 1mm/1000mm Max for cold drawn bars and 3mm/1000mm Max for hot rolled/forged products, ensuring parts align correctly during assembly.

Surface Finish | Turned | Milled | Grinding(Best) | Polished(Best) | Peeled(Best) | Black Forged | Black Rolled |

Tolerance | +0/+3mm | +0/+3mm | +0/+0.05mm | +0/+0.05mm | +0/+0.1mm | +0/+5mm | +0/+1mm |

Straighness | 1mm/1000mm max. | 3mm/1000mm max. | |||||

Our strict quality control processes ensure that all products meet the specified tolerances and surface finish requirements, providing our customers with the precision and reliability they need for their applications.

Qilu steel stock hot rolled bar and forged bars more than ten thousands tons every month, below our our stock size.

Stock diameter for hot rolled bar

20 | 22 | 25 | 28 | 30 | 32 | 35 | 38 | 40 | 42 | 45 | 48 | 50 | 55 | 60 |

65 | 70 | 75 | 80 | 85 | 90 | 95 | 100 | 105 | 110 | 115 | 120 | 125 | 130 | 140 |

150 | 160 | 170 | 180 | 190 | 200 | 210 | 220 | 230 | 240 | 250 | 260 | 270 | 280 | 290 |

300 |

AISI 1035 / DIN C35 1.0501 / JIS S35C / BS 060A35 is a versatile steel grade that finds applications in a wide range of industries. Its balanced mechanical properties, excellent machinability, and global availability make it a popular choice for various components and structures.

AISI 1035 / DIN C35 1.0501 is a staple in mechanical manufacturing, thanks to its balanced strength and machinability:

Gears & Shafts: QT-treated steel delivers 630-780 Mpa tensile strength and 28-32 HRC hardness, withstanding the rotational stress and wear of industrial gearboxes. Its low impurity levels (P ≤0.045%, S ≤0.045%) prevent fatigue cracking, extending the lifespan of these critical components. Gears and shafts made from this steel are used in a wide range of industrial machinery, including pumps, compressors, and conveyors.

Connecting Rods: Normalized or QT variants offer the ductility to absorb engine vibrations while maintaining the strength to handle combustion forces—making them ideal for diesel or gasoline engines in heavy equipment, such as tractors, construction machinery, and generators.

Bolts & Nuts: Cold drawn bars with +0/+0.1mm tolerance ensure precise threading, allowing them to handle high torque in applications like industrial presses, construction machinery, and automotive engines. The high strength and good corrosion resistance of this steel make bolts and nuts durable and reliable.

In the automotive sector, AISI 1035 / JIS S35C is used for components that demand reliability under harsh road conditions:

Drive Shafts: QT-treated steel’s ≥430 Mpa yield strength resists bending and torsion, critical for transmitting power from the engine to the wheels without failure.

Steering Components: The steel’s tight straightness tolerance (≤1mm/1000mm) ensures precise steering response, enhancing vehicle safety by reducing play in the steering system.

Chassis Parts: Hot rolled plates (3-200mm thickness) provide structural support for vehicle frames, with normalized tensile strength of ≥500 Mpa to withstand impacts from potholes or rough terrain.

Compared to more expensive alloy steels (e.g., AISI 4140), AISI 1035 offers a cost advantage for non-critical automotive parts while still meeting performance requirements.

While not a high-carbon tool steel, AISI 1035 / BS 060A35 excels in tool and mold applications requiring moderate hardness:

Mold Bases: Soft annealed steel (130-170 HBW) is easy to machine into custom mold shapes, with good dimensional stability during heating and cooling cycles—preventing warping in plastic injection molds.

Jigs & Fixtures: Cold drawn bars with a grinding finish (+0/+0.05mm tolerance) ensure tight alignment for workpieces during manufacturing, reducing errors in processes like drilling or milling.

Low-Stress Cutting Tools: Flame-hardened surfaces (48 HRC) provide sufficient wear resistance for cutting non-ferrous metals (e.g., aluminum) or plastics, making them a cost-effective choice for low-volume production.

In construction and civil engineering, DIN C35 1.0501 is used for medium-strength structural components:

Connectors & Brackets: Hot forged bars (Φ100-Φ1200mm) offer the strength to join steel beams in industrial buildings, with normalized yield strength of ≥245 Mpa to resist static and dynamic loads.

Support Frames: Hot rolled plates (width 1500-2500mm) are cut and welded into frames for bridges or warehouses, where their ductility (elongation ≥19%) absorbs seismic forces or wind loads.

Its broad supply range and machinability make AISI 1035 suitable for small, precision components across industries:

Pins & Sleeves: Cold drawn bars (Φ3-Φ80mm) are turned or milled into small parts for appliances or electronics, with +0/+0.1mm tolerance ensuring a perfect fit in assemblies.

Flanges: Hot rolled bars are forged into flanges for piping systems, with normalized properties ensuring leak-free seals under pressure—critical for water or gas distribution networks.

A1: Heat treatment is key to tailoring DIN C35 1.0501’s performance to specific needs:

Soft Annealing: Heating the steel to 680-720℃ and cooling it slowly in a furnace reduces hardness to 130-170 HBW, making it easy to machine into complex shapes like mold bases.

Normalizing: Heating to 860-900℃ and cooling in air refines the steel’s grain structure, resulting in tensile strength of 500-550 Mpa and elongation of ≥18%—ideal for general-purpose parts.

Quenching & Tempering (QT): First, heat the steel to 840-880℃ and quench it in water (lower end of the temperature range) or oil (higher end) to harden it. Then temper at 550-660℃ to balance strength and toughness, achieving tensile strength of 630-780 Mpa and yield strength of ≥430 Mpa for high-stress components.

Always adjust temperatures based on quenching medium to avoid cracking—water quenching requires lower temperatures to prevent thermal shock.

A2: JIS S35C has poor weldability because its carbon content (0.32-0.38%) exceeds the 0.25% threshold where weld cracking risk increases. Carbon reacts with oxygen during welding to form brittle carbides, leading to cracks in the heat-affected zone (HAZ). To improve weldability:

Preheat the Base Metal: Warm the steel to 200-300℃ before welding to reduce thermal stress between the hot weld and cold base metal.

Use Low-Hydrogen Electrodes: Electrodes like E7018 minimize hydrogen absorption, which is a major cause of post-weld cracking.

Post-Weld Heat Treatment (PWHT): After welding, temper the steel at 550-600℃ to relieve residual stress and soften the HAZ, reducing brittleness.

Avoid welding JIS S35C in thick sections (>20mm) without preheating, as thicker material traps more stress and increases cracking risk.

A3: AISI 1035 is suitable for medium-wear applications (e.g., gear teeth, shaft journals) but not extreme wear scenarios (e.g., mining conveyor parts). To enhance its wear resistance:

Flame or Induction Hardening: Creates a surface hardness of 48 HRC, which resists moderate friction and extends part life.

Quenching & Tempering: QT treatment increases core hardness to 28-32 HRC, improving overall wear resistance compared to normalized steel.

For extreme wear, choose alloy steels like AISI 4140 (which has added Cr and Mo for better wear resistance) or apply surface coatings (e.g., chrome plating, nitriding). AISI 1035’s carbon content is too low to achieve ultra-high hardness (>50 HRC) without sacrificing toughness, making it unsuitable for severe wear.

A4: AISI 1035 and AISI 1045 are both medium carbon steels, but they differ in carbon content, mechanical properties, and applications:

Carbon Content: AISI 1035 has a carbon content of 0.32-0.38%, while AISI 1045 has a higher carbon content of 0.42-0.48%.

Mechanical Properties: AISI 1045 has higher tensile strength and hardness than AISI 1035. In the normalized condition, AISI 1045 has a tensile strength of 600-750 Mpa, while AISI 1035 has a tensile strength of 500-550 Mpa. In the quenched and tempered condition, AISI 1045 can achieve tensile strengths up to 900 Mpa, compared to 630-780 Mpa for AISI 1035.

Machinability: AISI 1035 has better machinability than AISI 1045 due to its lower carbon content. It is easier to cut, drill, and machine, making it suitable for parts that require extensive machining.

Applications: AISI 1035 is ideal for general-purpose parts like brackets, pins, flanges, gears, and shafts that require a balance of strength and machinability. AISI 1045 is used for parts that require higher strength and hardness, such as gears, shafts, connecting rods, and tool holders.

The choice between AISI 1035 and AISI 1045 depends on the specific requirements of the application. If machinability and a balance of strength and ductility are important, AISI 1035 is a good choice. If higher strength and hardness are required, AISI 1045 is more suitable.

A5: AISI 1035 is a carbon steel and does not have inherent corrosion resistance. It is prone to rust and corrosion when exposed to moisture, oxygen, and other corrosive environments. To improve its corrosion resistance, the following measures can be taken:

Painting or Coating: Applying paint, enamel, or other organic coatings can protect the steel from corrosion. These coatings form a barrier between the steel and the environment, preventing moisture and oxygen from reaching the surface.

Galvanizing: Hot-dip galvanizing or electro-galvanizing can provide excellent corrosion resistance. Galvanizing involves coating the steel with a layer of zinc, which acts as a sacrificial anode, protecting the steel from corrosion.

Stainless Steel Cladding: Cladding the surface of AISI 1035 with stainless steel can provide corrosion resistance while maintaining the strength and machinability of the carbon steel.

Cathodic Protection: For submerged or buried structures, cathodic protection can be used to prevent corrosion. This involves applying a direct current to the steel, which reduces the corrosion rate.

It is important to note that these corrosion protection measures add to the cost of the steel and may affect its mechanical properties. The choice of corrosion protection method depends on the application environment and the required service life of the part.

A6: Yes, AISI 1035 Steel can be cold-formed, but its cold-formability depends on the processing condition and the complexity of the part. In the soft annealed condition (130-170 HBW), the steel has good ductility and can be cold-formed into simple shapes like bends, curves, and stampings. However, cold-forming may cause work hardening, which increases the steel’s hardness and reduces its ductility.

For complex cold-formed parts or parts that require tight tolerances, it is recommended to:

Anneal the Steel Before Cold-Forming: Soft annealing reduces the steel’s hardness and improves its ductility, making it easier to cold-form.

Use Proper Lubrication: Applying lubrication during cold-forming reduces friction between the steel and the tooling, preventing galling and improving the surface finish of the part.

Control the Cold-Forming Process: Using appropriate forming speeds, pressures, and tooling designs can help to minimize work hardening and ensure the part meets the required dimensional tolerances.

After cold-forming, the steel may require heat treatment (such as stress relieving or annealing) to restore its ductility and reduce internal stresses.

A7: To prevent corrosion of AISI 1035 Steel during storage, the following steps should be taken:

Store in a Dry Environment: Keep the steel in a dry, well-ventilated area to prevent moisture from accumulating on the surface. Avoid storing the steel in damp basements, outdoor areas, or areas with high humidity.

Protect from Moisture: Cover the steel with a waterproof material such as plastic sheeting or tarpaulin to protect it from rain, snow, and other sources of moisture. If the steel is stored outdoors, it should be elevated off the ground to prevent contact with water and soil.

Apply a Rust Inhibitor: Coating the steel with a rust inhibitor (such as oil, grease, or a corrosion-resistant spray) can help to prevent corrosion. Rust inhibitors form a protective layer on the steel’s surface, preventing moisture and oxygen from reaching the metal.

Inspect Regularly: Regularly inspect the steel for signs of corrosion, such as rust or discoloration. If corrosion is detected, it should be removed immediately using a wire brush, sandpaper, or other cleaning tools, and the steel should be re-protected.

By following these storage guidelines, the risk of corrosion can be minimized, ensuring that the steel remains in good condition for use.

If you have any questions about AISI 1035 / DIN C35 1.0501 / JIS S35C / BS 060A35 Carbon Steel or need a custom quote, please contact Hunan Qilu Steel’s sales team. We are committed to providing our customers with high-quality products, competitive prices, and excellent customer service.

WhatsApp: +86-15084978853

Email: enquiry@qilusteel.com

AISI 1035 / DIN C35 1.0501 / JIS S35C / BS 060A35 is a versatile medium carbon steel that stands out in the manufacturing industry for its balanced blend of strength, ductility, and machinability. Classified under international standards including American Standard ASTM 1035 (ASTM A20), Japanese Standard S35C (JIS G4051), Chinese Standard 35# (GB/T 699), and British Standard 060A35 (BS 970), this steel grade has become a go-to choice for engineers and manufacturers worldwide.

With a carbon content ranging from 0.32% to 0.39%, it strikes the perfect balance between the brittleness of high-carbon steels (such as AISI 1060) and the lower tensile strength of low-carbon steels (like AISI 1020). This unique composition allows it to retain excellent ductility while delivering sufficient strength to meet the demands of most engineering applications. Whether used in its as-rolled, normalized, or quenched and tempered state, this steel consistently delivers reliable performance, making it suitable for a wide range of industries, from mechanical manufacturing and automotive production to tool and mold making, architectural structures, and beyond.

Country | USA | Europe | China | British | Japan |

Standard | ASTM A29 | EN10083-2 | GB/T699 | BS970 | JIS G4051 |

Grade | 1035 | C35/1.0501 | 35# | 060A35 | S35C |

The chemical makeup of AISI 1035 / DIN C35 1.0501 / JIS S35C / BS 060A35 is tightly controlled to ensure uniform performance across every batch. Each element plays a critical role in shaping the steel’s properties:

Carbon (C): 0.32-0.39%: The primary strengthener, balancing hardness for load-bearing capacity and toughness to resist cracking under impact.

Manganese (Mn): 0.50-0.90%: Improves hardenability (helping the steel respond better to heat treatment) and enhances machinability by reducing friction between the steel and cutting tools.

Silicon (Si): ≤0.40% Max: Boosts strength during heat treatment without making the steel overly brittle, with strict limits to avoid compromising ductility.

Phosphorus (P) & Sulfur (S): ≤0.045% Max Each: Minimized to prevent brittleness and cracking, especially during welding or forging.

Trace Elements (Cr, Mo, Ni): ≤0.40% Max: Chromium (Cr), molybdenum (Mo), and nickel (Ni) are present in small amounts to enhance overall stability—for example, JIS S35C limits Cr to ≤0.20% to maintain its machinability.

Grade | C | Si | Mn | P | S | Cr | Mo | Ni |

1035 | 0.32-0.38 | / | 0.60-0.90 | 0.040Max | 0.050Max | / | / | / |

C35/1.0501 | 0.32-0.39 | 0.40Max | 0.50-0.80 | 0.045Max | 0.045Max | 0.40Max | 0.10Max | 0.40Max |

35# | 0.32-0.39 | 0.17-0.37 | 0.50-0.80 | 0.035Max | 0.035Max | 0.25Max | / | 0.30Max |

S35C | 0.32-0.38 | 0.15-0.35 | 0.60-0.90 | 0.030Max | 0.035Max | 0.20Max | / | / |

This well-balanced chemical composition ensures the steel behaves predictably during processing, whether undergoing annealing, normalizing, quenching and tempering, or other heat treatment processes, and delivers consistent performance in end-use applications.

The mechanical performance of AISI 1035 / DIN C35 1.0501 / JIS S35C / BS 060A35 varies by processing condition, allowing manufacturers to select the right state for their specific use case. Below is a detailed breakdown of its mechanical properties under different conditions:

Size range | Tensile strength | Yield strength | Alongation | Area of reduction | Impact value At RT/J |

d≤16 t≤8 | 630-780Mpa | 430Mpa Min | 17% Min | 40% Min | / |

16<d≤40 8<t≤20 | 600-750Mpa | 380Mpa Min | 19% Min | 45%Min | / |

Size range | Tensile strength | Yield strength | Alongation | Area of reduction | Impact value At RT/J |

d≤16 t≤16 | 550Mpa | 300Mpa Min | 18% Min | / | / |

16<d≤100 16<t≤100 | 520Mpa | 270Mpa Min | 19% Min | / | / |

100<d≤250 100<t≤250 | 500Mpa | 245Mpa Min | 19% Min | / | / |

Sampling and preparation of test pieces for C35 quenching and tempering steel.

1): According to EN10083-1, all samples shall be taken at a distance of 12.5mm below the heat treated surface

2): As stipulated in the contract between buyer and seller.

Mechanical properties for C35 open die forgings steel in the normalized and normalized and tempered conditions according to EN10250-2.

Mechanical properties for C35 open die forgings steel in the normalized or normalized and tempered conditions according to EN10250-2.

Size range | Tensile strength | Yield strength | Alongation | Impact value at RT/J | ||

L | Tr | L | Tr | |||

d≤100 | 520Mpa Min | 270Mpa Min | 19% Min | / | 30J Min | / |

100<d≤250 | 500Mpa Min | 245Mpa Min | 19% Min | 15% Min | 25J Min | 15J Min |

250<d≤500 | 480Mpa Min | 220Mpa Min | 19% Min | 15% Min | 20J Min | 12J Min |

500<d≤1000 | 470Mpa Min | 210Mpa Min | 18% Min | 14% Min | 17J Min | 12J Min |

Mechanical properties for C35 open die forgings steel in the quenched and tempered conditions according to EN10250-2.

Size range | Tensile strength | Yield strength | Alongation | Impact value at RT/J | ||

L | Tr | L | Tr | |||

d≤70 | 550Mpa Min | 320Mpa Min | 20% Min | / | 35J Min | / |

70<d≤160 | 490Mpa Min | 290Mpa Min | 22% Min | 15% Min | 31J Min | 20J Min |

160<d≤330 | 270Mpa Min | 270Mpa Min | 21% Min | 14% Min | 25J Min | 16J Min |

Remark: L= Longitudinal Tr = Transverse

Sampling and preparation of test pieces for steel forging.

1: According to EN10250-1, all samples shall be taken at a distance of 4/T below the heat treated surface (with a minimum of 20mm and a maximum of 80mm), and t/2 from the end (where t is the equivalent thickness of the thickness of the ruling section of the forging at the time of heat treatment.

2: As stipulated in the contract between buyer and seller.

These mechanical properties make the steel highly adaptable. In the normalized condition, it is ideal for low-to-medium stress parts like brackets, pins, and flanges. When quenched and tempered, it delivers enhanced strength and toughness, making it suitable for high-stress components such as gears, shafts, connecting rods, and drive shafts. Open die forgings, available in various sizes, offer excellent durability for heavy machinery parts like forged shafts and large structural components.

AISI 1035 / DIN C35 1.0501 / JIS S35C / BS 060A35 offers reliable hardenability, a key factor for parts requiring wear-resistant surfaces. The steel’s hardenability can be tailored to meet specific application requirements through different heat treatment processes:

Flame or Induction Hardening: Achieves a surface hardness of 48 HRC, ideal for parts like gear teeth and shaft journals that face repeated friction.

Soft Annealed (+A): Reduces hardness to 130-170 HBW, making the steel easy to machine into precision parts like jigs or mold bases.

Quenched & Tempered (+QT): Common hardness range is 28-32 HRC, balancing strength and toughness for load-bearing components.

Heat Treatment | Hardness |

Flame or Induction hardening | 48HRC |

Treated to improve shearability (+S) | 150-200HBW |

Soft annealed (+A) | 130-170HBW |

Quenched and tempred (+QT) | HRC28-32(Common Range) |

+HH14 (High Hardenability): At 1mm from the quenched end, hardness ranges from 48-58 HRC; at 4mm, it stays at 34-53 HRC, suitable for parts needing deep hardness penetration.

+HL14 (Low Hardenability): At 4mm from the quenched end, hardness is 24-43 HRC, ideal for parts where uniform hardness across the section is more important than deep penetration.

Where the steel is ordered by using the symbols for normal (+H) or restricted (+HL, +HH) hardenability requirements, the hardenability values should apply below:

Distance in mm from quenched end | ||||||||||||||

Distance | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 13 | 15 | |

Hardness In HRC + H | max | 58 | 57 | 55 | 53 | 49 | 41 | 34 | 31 | 28 | 27 | 26 | 25 | 24 |

min | 48 | 40 | 33 | 24 | 22 | 20 | / | / | / | / | / | / | / | |

Hardness In HRC + HH | +HH4 | / | / | / | 34-53 | / | / | / | / | / | / | / | / | / |

+HH14 | 51-58 | / | / | 34-53 | / | / | / | / | / | / | / | / | / | |

Hardness In HRC + HL | +HL4 | / | / | / | 24-43 | / | / | / | / | / | / | / | / | / |

+HL14 | 48-55 | / | / | 24-43 | / | / | / | / | / | / | / | / | / | |

The ability to adjust the steel hardenability and surface hardness makes it highly versatile, allowing it to meet the specific wear resistance and strength requirements of a wide range of applications.

Scatter bands for the Rockwell - C hardness in the end quench hardenability test.

Hunan Qilu Steel provides AISI 1035 / DIN C35 1.0501 / JIS S35C / BS 060A35 in a wide range of forms and sizes, with strict tolerances to meet diverse precision requirements. Our commitment to quality ensures that every product meets or exceeds international standards, providing our customers with reliable and consistent performance:

Cold Drawn Bar: Diameter Φ3-Φ80mm, length 6000-9000mm—perfect for small, precision parts like electronic pins or fasteners.

Hot Rolled Bar: Diameter Φ16-Φ300mm, length 6000-9000mm—cost-effective for medium-sized components like brackets or lever arms.

Hot Forged Bar: Diameter Φ100-Φ1200mm, length 3000-5800mm—ideal for heavy machinery parts like large shafts or forged blocks.

Hot Rolled Plate/Sheet: Thickness 3-200mm, width 1500-2500mm, length 2000-5800mm—versatile for structural applications like building supports or machine frames.

Product type | Size range | Length |

Cold drawn bar | Φ3-Φ80mm | 6000-9000mm |

Hot rolled bar | Φ16-Φ300mm | 6000-9000mm |

Hot forged bar | Φ100-Φ1200mm | 3000-5800mm |

Hot rolled plate/sheet | T:3-200mm; W:1500-2500mm | 2000-5800mm |

Hot Forged block | T: 80-800mm; W: 100-2500mm | 2000-5800mm |

Grinding or Polished Finish: Tolerance of +0/+0.05mm, the highest precision for critical parts like mold cores or precision shafts.

Peeled Finish: Tolerance of +0/+0.1mm, excellent for machined components where surface smoothness is key.

Hot Rolled or Black Forged Finish: Tolerance ranges from +0/+1mm (hot rolled) to +0/+5mm (black forged), cost-efficient for non-precision parts like rough structural brackets.

Straightness: 1mm/1000mm Max for cold drawn bars and 3mm/1000mm Max for hot rolled/forged products, ensuring parts align correctly during assembly.

Surface Finish | Turned | Milled | Grinding(Best) | Polished(Best) | Peeled(Best) | Black Forged | Black Rolled |

Tolerance | +0/+3mm | +0/+3mm | +0/+0.05mm | +0/+0.05mm | +0/+0.1mm | +0/+5mm | +0/+1mm |

Straighness | 1mm/1000mm max. | 3mm/1000mm max. | |||||

Our strict quality control processes ensure that all products meet the specified tolerances and surface finish requirements, providing our customers with the precision and reliability they need for their applications.

Qilu steel stock hot rolled bar and forged bars more than ten thousands tons every month, below our our stock size.

Stock diameter for hot rolled bar

20 | 22 | 25 | 28 | 30 | 32 | 35 | 38 | 40 | 42 | 45 | 48 | 50 | 55 | 60 |

65 | 70 | 75 | 80 | 85 | 90 | 95 | 100 | 105 | 110 | 115 | 120 | 125 | 130 | 140 |

150 | 160 | 170 | 180 | 190 | 200 | 210 | 220 | 230 | 240 | 250 | 260 | 270 | 280 | 290 |

300 |

AISI 1035 / DIN C35 1.0501 / JIS S35C / BS 060A35 is a versatile steel grade that finds applications in a wide range of industries. Its balanced mechanical properties, excellent machinability, and global availability make it a popular choice for various components and structures.

AISI 1035 / DIN C35 1.0501 is a staple in mechanical manufacturing, thanks to its balanced strength and machinability:

Gears & Shafts: QT-treated steel delivers 630-780 Mpa tensile strength and 28-32 HRC hardness, withstanding the rotational stress and wear of industrial gearboxes. Its low impurity levels (P ≤0.045%, S ≤0.045%) prevent fatigue cracking, extending the lifespan of these critical components. Gears and shafts made from this steel are used in a wide range of industrial machinery, including pumps, compressors, and conveyors.

Connecting Rods: Normalized or QT variants offer the ductility to absorb engine vibrations while maintaining the strength to handle combustion forces—making them ideal for diesel or gasoline engines in heavy equipment, such as tractors, construction machinery, and generators.

Bolts & Nuts: Cold drawn bars with +0/+0.1mm tolerance ensure precise threading, allowing them to handle high torque in applications like industrial presses, construction machinery, and automotive engines. The high strength and good corrosion resistance of this steel make bolts and nuts durable and reliable.

In the automotive sector, AISI 1035 / JIS S35C is used for components that demand reliability under harsh road conditions:

Drive Shafts: QT-treated steel’s ≥430 Mpa yield strength resists bending and torsion, critical for transmitting power from the engine to the wheels without failure.

Steering Components: The steel’s tight straightness tolerance (≤1mm/1000mm) ensures precise steering response, enhancing vehicle safety by reducing play in the steering system.

Chassis Parts: Hot rolled plates (3-200mm thickness) provide structural support for vehicle frames, with normalized tensile strength of ≥500 Mpa to withstand impacts from potholes or rough terrain.

Compared to more expensive alloy steels (e.g., AISI 4140), AISI 1035 offers a cost advantage for non-critical automotive parts while still meeting performance requirements.

While not a high-carbon tool steel, AISI 1035 / BS 060A35 excels in tool and mold applications requiring moderate hardness:

Mold Bases: Soft annealed steel (130-170 HBW) is easy to machine into custom mold shapes, with good dimensional stability during heating and cooling cycles—preventing warping in plastic injection molds.

Jigs & Fixtures: Cold drawn bars with a grinding finish (+0/+0.05mm tolerance) ensure tight alignment for workpieces during manufacturing, reducing errors in processes like drilling or milling.

Low-Stress Cutting Tools: Flame-hardened surfaces (48 HRC) provide sufficient wear resistance for cutting non-ferrous metals (e.g., aluminum) or plastics, making them a cost-effective choice for low-volume production.

In construction and civil engineering, DIN C35 1.0501 is used for medium-strength structural components:

Connectors & Brackets: Hot forged bars (Φ100-Φ1200mm) offer the strength to join steel beams in industrial buildings, with normalized yield strength of ≥245 Mpa to resist static and dynamic loads.

Support Frames: Hot rolled plates (width 1500-2500mm) are cut and welded into frames for bridges or warehouses, where their ductility (elongation ≥19%) absorbs seismic forces or wind loads.

Its broad supply range and machinability make AISI 1035 suitable for small, precision components across industries:

Pins & Sleeves: Cold drawn bars (Φ3-Φ80mm) are turned or milled into small parts for appliances or electronics, with +0/+0.1mm tolerance ensuring a perfect fit in assemblies.

Flanges: Hot rolled bars are forged into flanges for piping systems, with normalized properties ensuring leak-free seals under pressure—critical for water or gas distribution networks.

A1: Heat treatment is key to tailoring DIN C35 1.0501’s performance to specific needs:

Soft Annealing: Heating the steel to 680-720℃ and cooling it slowly in a furnace reduces hardness to 130-170 HBW, making it easy to machine into complex shapes like mold bases.

Normalizing: Heating to 860-900℃ and cooling in air refines the steel’s grain structure, resulting in tensile strength of 500-550 Mpa and elongation of ≥18%—ideal for general-purpose parts.

Quenching & Tempering (QT): First, heat the steel to 840-880℃ and quench it in water (lower end of the temperature range) or oil (higher end) to harden it. Then temper at 550-660℃ to balance strength and toughness, achieving tensile strength of 630-780 Mpa and yield strength of ≥430 Mpa for high-stress components.

Always adjust temperatures based on quenching medium to avoid cracking—water quenching requires lower temperatures to prevent thermal shock.

A2: JIS S35C has poor weldability because its carbon content (0.32-0.38%) exceeds the 0.25% threshold where weld cracking risk increases. Carbon reacts with oxygen during welding to form brittle carbides, leading to cracks in the heat-affected zone (HAZ). To improve weldability:

Preheat the Base Metal: Warm the steel to 200-300℃ before welding to reduce thermal stress between the hot weld and cold base metal.

Use Low-Hydrogen Electrodes: Electrodes like E7018 minimize hydrogen absorption, which is a major cause of post-weld cracking.

Post-Weld Heat Treatment (PWHT): After welding, temper the steel at 550-600℃ to relieve residual stress and soften the HAZ, reducing brittleness.

Avoid welding JIS S35C in thick sections (>20mm) without preheating, as thicker material traps more stress and increases cracking risk.

A3: AISI 1035 is suitable for medium-wear applications (e.g., gear teeth, shaft journals) but not extreme wear scenarios (e.g., mining conveyor parts). To enhance its wear resistance:

Flame or Induction Hardening: Creates a surface hardness of 48 HRC, which resists moderate friction and extends part life.

Quenching & Tempering: QT treatment increases core hardness to 28-32 HRC, improving overall wear resistance compared to normalized steel.

For extreme wear, choose alloy steels like AISI 4140 (which has added Cr and Mo for better wear resistance) or apply surface coatings (e.g., chrome plating, nitriding). AISI 1035’s carbon content is too low to achieve ultra-high hardness (>50 HRC) without sacrificing toughness, making it unsuitable for severe wear.

A4: AISI 1035 and AISI 1045 are both medium carbon steels, but they differ in carbon content, mechanical properties, and applications:

Carbon Content: AISI 1035 has a carbon content of 0.32-0.38%, while AISI 1045 has a higher carbon content of 0.42-0.48%.

Mechanical Properties: AISI 1045 has higher tensile strength and hardness than AISI 1035. In the normalized condition, AISI 1045 has a tensile strength of 600-750 Mpa, while AISI 1035 has a tensile strength of 500-550 Mpa. In the quenched and tempered condition, AISI 1045 can achieve tensile strengths up to 900 Mpa, compared to 630-780 Mpa for AISI 1035.

Machinability: AISI 1035 has better machinability than AISI 1045 due to its lower carbon content. It is easier to cut, drill, and machine, making it suitable for parts that require extensive machining.

Applications: AISI 1035 is ideal for general-purpose parts like brackets, pins, flanges, gears, and shafts that require a balance of strength and machinability. AISI 1045 is used for parts that require higher strength and hardness, such as gears, shafts, connecting rods, and tool holders.

The choice between AISI 1035 and AISI 1045 depends on the specific requirements of the application. If machinability and a balance of strength and ductility are important, AISI 1035 is a good choice. If higher strength and hardness are required, AISI 1045 is more suitable.

A5: AISI 1035 is a carbon steel and does not have inherent corrosion resistance. It is prone to rust and corrosion when exposed to moisture, oxygen, and other corrosive environments. To improve its corrosion resistance, the following measures can be taken:

Painting or Coating: Applying paint, enamel, or other organic coatings can protect the steel from corrosion. These coatings form a barrier between the steel and the environment, preventing moisture and oxygen from reaching the surface.

Galvanizing: Hot-dip galvanizing or electro-galvanizing can provide excellent corrosion resistance. Galvanizing involves coating the steel with a layer of zinc, which acts as a sacrificial anode, protecting the steel from corrosion.

Stainless Steel Cladding: Cladding the surface of AISI 1035 with stainless steel can provide corrosion resistance while maintaining the strength and machinability of the carbon steel.

Cathodic Protection: For submerged or buried structures, cathodic protection can be used to prevent corrosion. This involves applying a direct current to the steel, which reduces the corrosion rate.

It is important to note that these corrosion protection measures add to the cost of the steel and may affect its mechanical properties. The choice of corrosion protection method depends on the application environment and the required service life of the part.

A6: Yes, AISI 1035 Steel can be cold-formed, but its cold-formability depends on the processing condition and the complexity of the part. In the soft annealed condition (130-170 HBW), the steel has good ductility and can be cold-formed into simple shapes like bends, curves, and stampings. However, cold-forming may cause work hardening, which increases the steel’s hardness and reduces its ductility.

For complex cold-formed parts or parts that require tight tolerances, it is recommended to:

Anneal the Steel Before Cold-Forming: Soft annealing reduces the steel’s hardness and improves its ductility, making it easier to cold-form.

Use Proper Lubrication: Applying lubrication during cold-forming reduces friction between the steel and the tooling, preventing galling and improving the surface finish of the part.

Control the Cold-Forming Process: Using appropriate forming speeds, pressures, and tooling designs can help to minimize work hardening and ensure the part meets the required dimensional tolerances.

After cold-forming, the steel may require heat treatment (such as stress relieving or annealing) to restore its ductility and reduce internal stresses.

A7: To prevent corrosion of AISI 1035 Steel during storage, the following steps should be taken:

Store in a Dry Environment: Keep the steel in a dry, well-ventilated area to prevent moisture from accumulating on the surface. Avoid storing the steel in damp basements, outdoor areas, or areas with high humidity.

Protect from Moisture: Cover the steel with a waterproof material such as plastic sheeting or tarpaulin to protect it from rain, snow, and other sources of moisture. If the steel is stored outdoors, it should be elevated off the ground to prevent contact with water and soil.

Apply a Rust Inhibitor: Coating the steel with a rust inhibitor (such as oil, grease, or a corrosion-resistant spray) can help to prevent corrosion. Rust inhibitors form a protective layer on the steel’s surface, preventing moisture and oxygen from reaching the metal.

Inspect Regularly: Regularly inspect the steel for signs of corrosion, such as rust or discoloration. If corrosion is detected, it should be removed immediately using a wire brush, sandpaper, or other cleaning tools, and the steel should be re-protected.

By following these storage guidelines, the risk of corrosion can be minimized, ensuring that the steel remains in good condition for use.

If you have any questions about AISI 1035 / DIN C35 1.0501 / JIS S35C / BS 060A35 Carbon Steel or need a custom quote, please contact Hunan Qilu Steel’s sales team. We are committed to providing our customers with high-quality products, competitive prices, and excellent customer service.

WhatsApp: +86-15084978853

Email: enquiry@qilusteel.com