English

T: +86-0731-85185770

E: enquiry@qilumetal.com

E: enquiry@qilumetal.com

No. 18 Xiangfu Middle Road,Yuhua District, Changsha City

Views: 0 Author: Site Editor Publish Time: 2025-10-20 Origin: Site

You need a material that can do hard work. It should not lose its shape or strength. Spring steel is different from other strong materials. It has special features. Many industries use spring steel. For example, cars and airplanes need it. They use it for important parts. These parts face stress and wear all the time. Spring steel has high yield strength. This means it does not change shape forever when bent or twisted. You will see these special features:

Great elasticity, so it goes back to its shape

Fatigue resistance, so it can handle many loads

Wear and abrasion resistance, so it lasts long

These features make spring steel a great choice. It is good when you need something strong and flexible.

Spring steel is very strong and bends easily. It goes back to its shape after bending. This makes it good for car springs and clips.

Pick the right spring steel for your needs. Each type has special features for different jobs.

Spring steel costs less than titanium and composites. It gives good strength and bends well for the price.

Think about rust when using spring steel. Coatings and treatments help it last longer in tough places.

Always use the best material for the job. Look at strength, flexibility, rust protection, and cost before you choose.

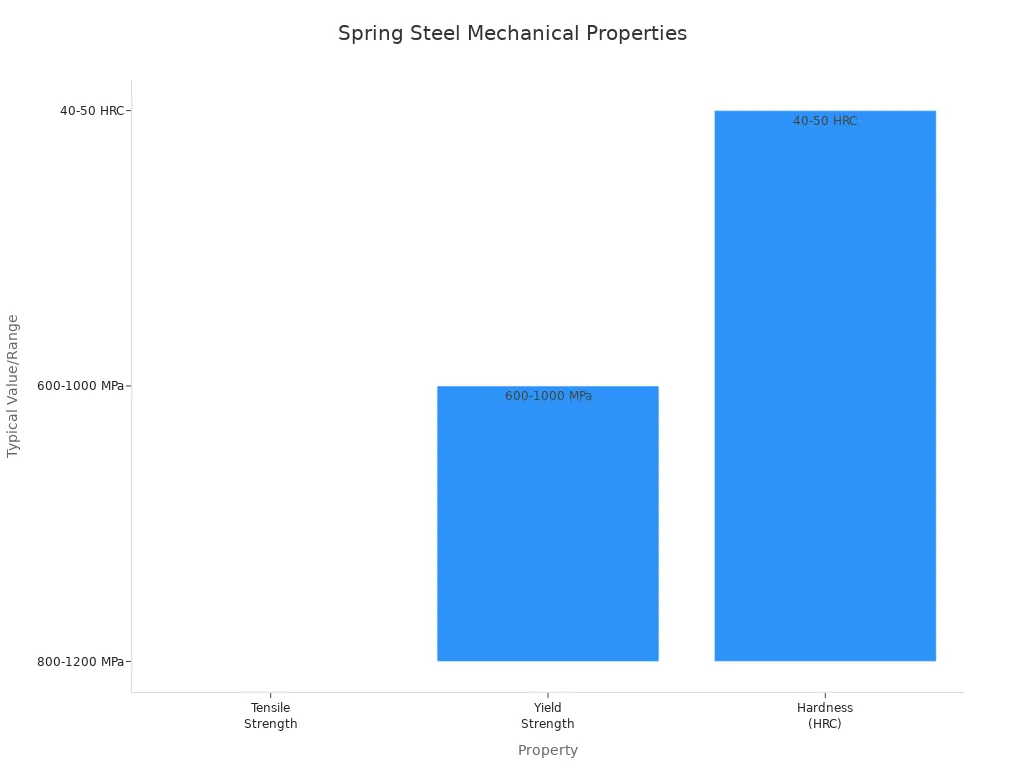

Spring steel is strong and tough. It can hold heavy things. It goes back to its shape after bending. This is good for parts that move a lot. Look at the table to see its main properties:

Property | Condition/Temper | Test Temperature | Typical Value/Range (Metric) | Typical Value/Range (Imperial) |

|---|---|---|---|---|

Tensile Strength | Quenched & Tempered | Room Temp | 800 - 1200 MPa | 116,000 - 174,000 psi |

Yield Strength (0.2%) | Quenched & Tempered | Room Temp | 600 - 1000 MPa | 87,000 - 145,000 psi |

Hardness (HRC) | Quenched & Tempered | Room Temp | 40 - 50 HRC | 40 - 50 HRC |

Spring steel does not wear out fast. It works well in places with lots of movement. Its high yield strength keeps it from breaking.

There are many types of spring steel. Each type has different elements and jobs. The table shows the most common types and what they do:

Type of Spring Steel | Composition | Performance Characteristics |

|---|---|---|

High-carbon steel | Medium-to-high carbon (0.5-1.0%) | High yield strength, excellent mechanical properties |

Oil-tempered low-carbon | Low carbon content | Good flexibility and resilience |

Chrome silicon | Alloyed with chromium and silicon | High yield strength, good fatigue resistance |

Chrome vanadium | Alloyed with chromium and vanadium | Enhanced toughness and wear resistance |

Stainless steel | Varies (e.g., PH 15-7 Mo, Type 420) | Corrosion resistance, high tensile strength |

Beryllium copper | Copper alloy with beryllium | Excellent electrical conductivity, good corrosion resistance |

Phosphor bronze | Copper alloy with tin and phosphorus | Good mechanical properties, stress relaxation |

Nickel alloy steels | Nickel added for strength | High strength and corrosion resistance |

Titanium alloy steels | Titanium added for lightweight | Exceptional strength-to-weight ratio, good corrosion resistance |

Pick the type that fits your job. Chrome silicon is good for springs that get lots of stress.

Spring steel grades have different amounts of carbon. Each grade is used for special jobs. The table lists some grades and what they are best for:

Grade | Carbon Content | Typical Applications |

|---|---|---|

AISI 1050 | Low | Easily formable, can be heat treated for increased hardness. |

AISI 1074/75 | Medium | Spheroidized for formability, can be heat treated. |

AISI 1095 | High | Highest elasticity and fatigue values, can be heat treated. |

Commonly used in clips, fasteners, springs, medical equipment, and hand tools. |

You will see spring steel grades in:

Clips and fasteners

Springs of all kinds

Medical tools and devices

Machines like lawnmowers and pumps

Hand tools such as pliers and scissors

Other uses are:

Swords for training or fighting

Lockpicks

Landing gear for planes

Knives and machetes

Electrician's fish tape

Tip: Always pick the right grade for your job. This helps your parts work better and last longer.

Stainless steel is used where strength and cleanliness are important. It does not rust or corrode easily. You see it in kitchens, hospitals, cars, and ships. Stainless steel works well in wet places and salty water. It can handle high heat and keeps its shape. The table shows why many people pick stainless steel instead of spring steel for some jobs:

Characteristic/Application | Description |

|---|---|

Corrosion Resistance | Stainless steel does not rust, so it works well with water and other liquids. |

Durability | It is strong and lasts a long time, even with heavy use in kitchens and hospitals. |

Hygienic Properties | It is easy to clean because it does not have tiny holes, which is good for food and medical places. |

High-Temperature Tolerance | Stainless steel can take high heat, so it is used in planes and gas turbines. |

Marine Applications | It is used in ships because it does not get damaged by saltwater or stress. |

Automotive Use | You find it in car parts like exhausts and fuel tanks because it is tough. |

Construction Use | It is used on buildings to protect them from weather. |

You should use stainless steel if you need something strong and clean in hard places. Spring steel does not stop rust as well as stainless steel.

Tool steel is very tough and good for cutting and shaping things. You can make it harder by heating it. This steel is best for tools that need to stay sharp and not wear out. The table compares tool steel and spring steel:

Steel Type | Hardness Characteristics | Wear Resistance Characteristics |

|---|---|---|

Spring Steel | It is strong, bends well, and keeps a sharp edge. | It is hard and does not wear out fast, good for blades. |

Tool Steel | You can make it harder with heat, and it is very strong. | It does not wear out easily, great for cutting tools and precise jobs. |

Use tool steel for drills, saws, and dies. Spring steel is better for parts that bend and go back to their shape.

Titanium alloys are good when you need things to be light. They weigh less than spring steel. You can make titanium springs with fewer coils and smaller sizes. This helps cars and planes use less fuel. Titanium does not rust, so it works in chemical plants and ships. Titanium alloys help things work better and handle easier. Spring steel is not as light or strong as titanium alloys.

Tip: Pick titanium alloys for jobs where weight is very important.

Composites mix different materials to get the best qualities. They are strong but much lighter than spring steel. Composites also cut down vibration more than steel springs. They do not rust, so they last longer in tough places. You see composites in cars, especially in leaf springs, because they save fuel and make cars lighter. Spring steel is still used a lot, but composites give new choices for engineers today.

When you look at strong materials, you should check how much force they can take before they break or bend. Strength and flexibility are very important for moving parts or heavy loads. Spring steel is special because it is both strong and flexible. You can bend it, and it will go back to its shape. It does not get damaged easily.

Here is a table with the main properties for engineering:

Property | Description | Importance in Engineering Applications |

|---|---|---|

Tensile Strength | Ability to resist breaking under tension. | Critical for components experiencing pulling forces, like cables. |

Compressive Strength | Capacity to withstand compressive forces. | Essential for load-bearing structures, such as concrete pillars. |

Shear Strength | Resistance to forces acting parallel to the surface. | Important for fasteners and components like rivets. |

Yield Strength | Stress level at which material transitions from elastic to plastic behavior. | Crucial for ensuring safe and reliable design in engineering. |

Spring steel has high yield strength. This means it does not change shape forever when bent. Stainless steel and titanium alloys are not as strong as spring steel, but they still work well. Stainless steel can reach 621 MPa in tensile strength. Titanium alloys can reach about 434 MPa. Tool steel and composites are different, but spring steel is often best for springs and moving parts.

You can see how stiff or flexible materials are in the chart below. This is called modulus of elasticity:

Spring steel types like oil tempered MB, hard drawn MB, and music wire have a modulus of elasticity around 30 x 10^6 psi. Stainless steel types are a little lower, but close. This means both are flexible, but spring steel is more reliable when you need strength and bending.

Tip: Pick spring steel if you need something that bends and snaps back to its shape.

Fatigue resistance shows how well a material can handle being used over and over. If you use a part many times, you want it to last without breaking. Spring steel is very good at this. It is strong and bounces back, so it can take many cycles of stress.

Here is a table comparing tool steel and spring steel:

Aspect | Tool Steel | Spring Steel |

|---|---|---|

Hardness | Very High | High |

Elasticity | Moderate | High |

Resilience | Moderate | High |

Fatigue | Moderate | High |

Durability | High | High |

Machinability | Low | Moderate |

Applications | Cutting tools | Springs, tools |

Spring steel fights fatigue better than most other strong materials. You see this in car springs, which must work thousands of times. Small flaws or cracks can cause problems in strong steels. In spring steel, cracks can start from twisting or stretching, but its design helps stop early breaks.

Cracks from twisting start with repeated shear.

Cracks from pulling start inside the material.

Surface cracks can come from scratches or defects.

You should use spring steel for parts that need to bend many times. Its high yield strength and fatigue resistance make it great for springs, clips, and fasteners.

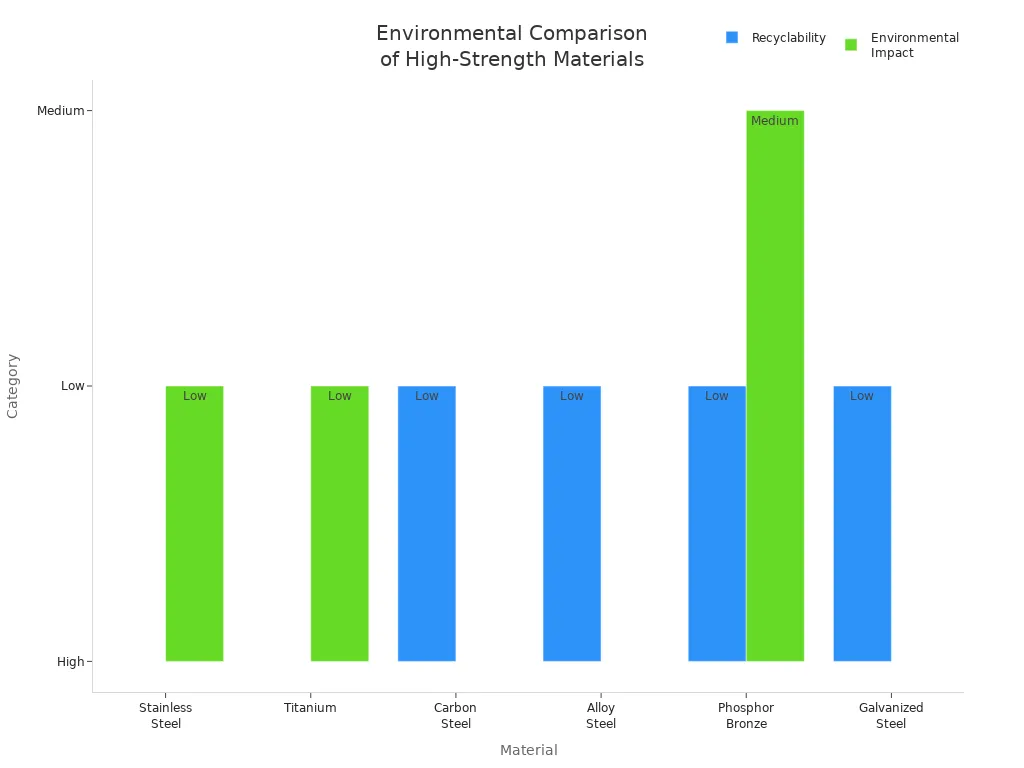

Corrosion resistance matters if your parts face water, chemicals, or salty air. Spring steel does not fight rust as well as stainless steel or titanium alloys. But you can make it better with special treatments.

Ways to help spring steel resist corrosion:

Add nickel to stop pitting.

Add copper to make a protective layer.

Use coatings to keep out water and chemicals.

Use shot peening to stop stress corrosion.

Use cathodic protection for extra safety.

Stainless steel does not rust and works well in wet places. Titanium alloys also fight corrosion, so they are good for ships or chemical plants. Composites do not rust at all. If you need a spring for tough places, pick stainless steel or coated spring steel.

Note: Always think about where you will use the material. Corrosion can make your parts wear out faster.

Cost is important when picking materials. Spring steel usually costs less than titanium alloys and composites. Stainless steel can cost more, especially for special types. Tool steel prices change based on type and treatment.

Here is a simple list to compare:

Spring steel: Cheap, easy to use, and easy to find.

Stainless steel: Costs more, but fights rust better.

Tool steel: Price changes, often higher because of special work.

Titanium alloys: Very expensive, but light and strong.

Composites: Cost a lot, but save weight and do not rust.

Spring steel gives you good value. You get strength and flexibility for a lower price.

Spring steel is used in many things because it is strong, flexible, and not too expensive. Here is a table with common uses for strong materials:

Material Type | Common Applications |

|---|---|

High-Carbon Spring Steel | Automotive mechanisms, compression springs in suspension systems |

Alloy Steels | Automotive suspension systems, heavy machinery, industrial and agricultural equipment |

You see spring steel in:

Car springs

Clips and fasteners

Hand tools

Medical devices

Lawn and garden tools

Other strong materials have their own uses:

Stainless steel: Kitchen tools, medical tools, boat parts

Tool steel: Cutting tools, dies, molds

Titanium alloys: Airplane parts, chemical plant tools, sports gear

Composites: Car springs, airplane parts, sports equipment

What you need the part to do helps you choose the material. For example, car springs must handle many loads. Airplane parts need to be strong and light, so engineers might pick titanium or special alloys.

Remember: Always match the material to the job. Think about strength, flexibility, rust resistance, and cost before you choose.

You need to pick the right material for your project. Spring steel is a good choice when you want something strong and flexible. Many businesses use spring steel because it can hold heavy things and go back to its shape. If you need parts that bend and snap back, spring steel works well.

Here are some ways people use spring steel:

Car springs in suspension systems

Machine parts like gears and shock absorbers

Airplane parts such as landing gear and controls

Building equipment that faces lots of pressure

Spring steel is great for these jobs because it does not wear out fast. It keeps working even after many bends. You can count on it for tough jobs that need strength and flexibility.

Think about where you will use spring steel. The table below shows how different grades handle heat and rust:

Material | Temperature Resistance | Corrosion Resistance | Common Applications |

|---|---|---|---|

Grade 302 Stainless Steel | Up to 550°F | Good | Medical, laboratory, industrial |

Grade 17-7 Stainless Steel | Up to 650°F | High | Automobile, energy, gas and oil |

Chrome Silicon | Moderate | Durable | High-impact applications |

Inconel Alloys | Up to 1,300°F | Excellent | Aerospace, nuclear energy |

Tip: Pick spring steel for parts that need to bend and last a long time.

Sometimes, spring steel is not the best choice. It can be hard to shape, cost more, or break more easily. You might also have trouble joining or cutting it, or stopping rust. In these cases, you should look at other strong materials.

You may want to use something else if you need:

Better rust protection for wet or salty places

Higher heat resistance for very hot jobs

Easier cutting or joining for tricky shapes

Stronger impact resistance for sudden hits

The place where you use spring steel can change how it works. Hot weather can make it slowly change shape. Cold weather can make it break more easily. Wet air can make it rust faster and get weaker.

Note: Always pick the material that fits your job and where you use it. If you need extra protection or special features, try stainless steel, titanium alloys, or composites.

You need to pick the right material for your project. Spring steel is special because it bends and goes back to its shape. It also absorbs energy well, which helps in car parts. Some materials, like stainless steel or titanium, do not rust easily. They can also be recycled better. The table below shows what each material does best and where it is used:

Material Type | Key Properties | Applications |

|---|---|---|

High-Carbon Spring Steels | High strength, durability | High fatigue resistance, strong springs |

Stainless Steels | Excellent corrosion resistance | Extreme environments, medical tools |

Chrome Silicon Spring Steel | Shock loading, cyclic fatigue resistance | Dynamic loads, high temperatures |

Do not forget to check for trade-offs. Always test your materials before using them. Pick spring steel if you need parts that bend and last a long time. Think about cost, the environment, and how long the part will work.

Spring steel bends and snaps back to its shape. Regular steel can bend but does not return as easily. You use spring steel for parts that need to move and stay strong.

You can use spring steel outside, but it may rust. You should add coatings or pick stainless spring steel for wet places. This helps your parts last longer.

Spring steel usually costs less than titanium or composites. You pay more for stainless steel or tool steel. Here is a quick price guide:

Material | Cost Level |

|---|---|

Spring Steel | Low |

Stainless | Medium |

Titanium | High |

Composites | High |

You find spring steel in car springs, hand tools, and clips. You also see it in airplane parts and machines. Spring steel works well in places that need strength and flexibility.

You can use coatings, paint, or oil to stop rust. Stainless spring steel resists rust better. Always keep your parts clean and dry for best results.