English

T: +86-0731-85185770

E: enquiry@qilumetal.com

E: enquiry@qilumetal.com

No. 18 Xiangfu Middle Road,Yuhua District, Changsha City

Views: 0 Author: Site Editor Publish Time: 2025-10-14 Origin: Site

You see metal tools break fast in hard jobs. Wear-resistant steel lasts much longer in tough places. Many companies use this steel to keep machines working.

Industry | Primary Applications |

|---|---|

Construction and Mining | Wear liners, rock breakers, bulldozers, excavator bucket liners |

Transportation and Automotive | Bulldozers, lorries, trailers, dump trucks |

Agriculture and Farming | Harvester blades, chutes, soil tilling equipment, plowshares |

This steel helps you save time and money. It stops damage from rough work.

Wear-resistant steel lasts much longer than regular steel. This makes it great for hard work in mining and construction. Using wear-resistant steel means less fixing and lower repair costs. This helps businesses save money over time. Wear-resistant steel is harder and stronger than regular steel. It can handle scratches and hits better. Picking the right grade of wear-resistant steel is important for each job. This helps machines work well and last longer. Wear-resistant steel can cost more at first. But it saves money by cutting down on breaks and helping work get done faster.

Wear-resistant steel is also called abrasion-resistant steel. It is a special steel that lasts longer when it rubs or hits things. You find this steel where regular steel wears out fast. People use the word abrasion-resistant for steel that fights damage from rough stuff. Wear-resistant steel protects against scratching, rubbing, hitting, and even some chemical or stress damage.

Wear-resistant steel is easy to spot because it is very hard and strong. It gets tough because it has more carbon and special elements. These elements are mixed in when the steel is made. They help the steel stay hard and strong after lots of use. The table below shows some elements and what they do:

Alloying Element | Role in Enhancing Wear Resistance |

|---|---|

Chrome (Cr) | Increases hardness and tensile strength; provides corrosion resistance. |

Manganese (Mn) | Improves hardness and ductility; acts as a deoxidiser. |

Vanadium (V) | Increases strength and wear resistance; refines grain structure. |

Tungsten (W) | Boosts hardness at high temperatures; essential for cutting tools. |

Boron (B) | Increases hardenability; useful in high-strength, wear-resistant steels. |

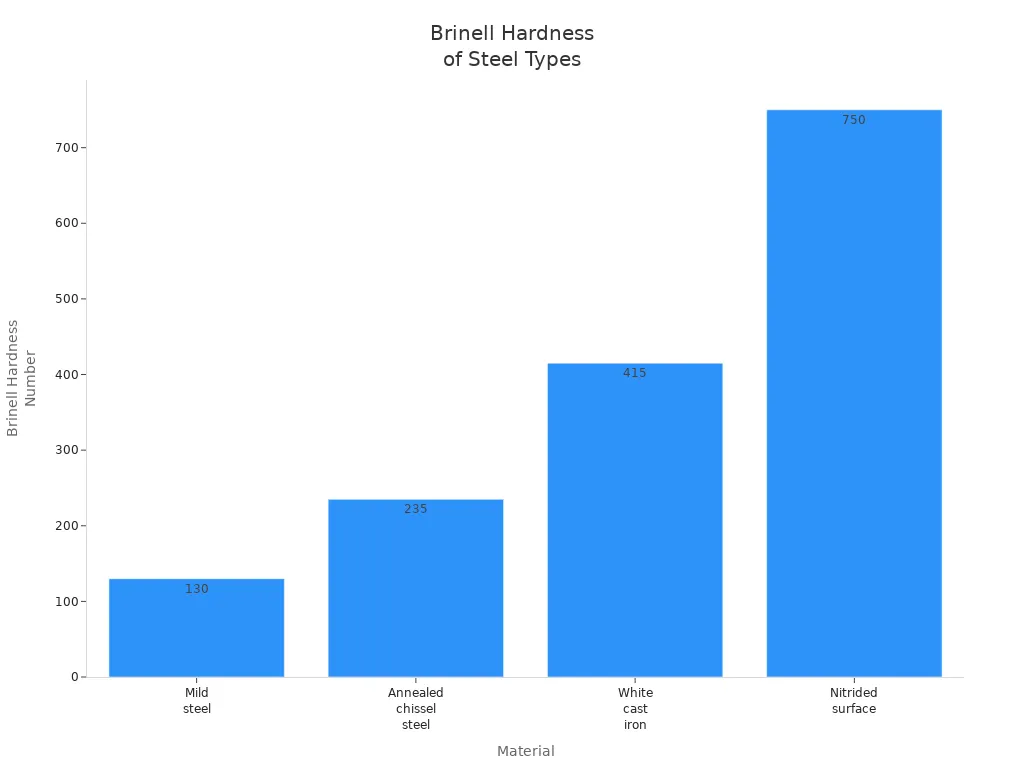

Wear-resistant steel is special because it can handle many kinds of wear. You can check how hard it is by looking at the Brinell Hardness Number (BHN). The chart below shows how hard different materials are:

For example, mild steel has a BHN of 130. Some abrasion-resistant steel can go over 500 BHN. This high hardness helps the steel last longer in hard jobs.

Factories use special steps to make wear-resistant steel. First, they mix in extra carbon and alloying elements. Next, they heat the steel and cool it fast. This is called quenching. Quenching makes the steel very hard. Then, they heat it again at a lower temperature. This is called tempering. Tempering makes the steel tough so it does not crack. By changing the heat and cooling, you can make the steel fit different jobs. It can fight impacts or last longer in rough places.

Many industries use different grades of wear-resistant steel. Here are some common grades and what they are used for:

Grade | Hardness (BHN) | Typical Applications |

|---|---|---|

AR200 | 170 - 250 | Truck liners, material chutes, bulk handling equipment |

AR235 | 12-14% Mn | Crusher hammers, mining equipment, railroad track work |

AR400 | 360 - 444 | Bucket liners, wear plates, hoppers |

AR450 | 420 - 470 | Dump truck bodies, heavy equipment parts, mining ops |

AR500 | 477 - 534 | Mining tools, construction machinery, military applications |

AR600 | 570 - 625 | Armor plating, excavation buckets, cutting edges |

Note: The right grade depends on how much wear and impact your equipment faces.

Steel must be strong for hard jobs. Hardness helps steel last longer. Wear-resistant steel stays tough after many uses. Its microstructure is very important. The steel has martensite and carbides inside. This makes the steel hard and durable.

Here is a table that shows how steel grades use their microstructure to get harder and tougher:

Steel Grade | Hardness (HB) | Microstructure Characteristics |

|---|---|---|

Hardox | 400-600 | Martensitic with fine-needle martensite and dispersed carbides |

XAR | 400-600 | Martensitic with fine-needle martensite and dispersed carbides |

Dillidur | 400-600 | Martensitic with fine-needle martensite and dispersed carbides |

Durostat | 400-600 | Martensitic with fine-needle martensite and dispersed carbides |

Abrazo | 400-600 | Martensitic with fine-needle martensite and dispersed carbides |

Steel with a bainitic matrix can lower defects. This helps the steel resist wear better. Retained austenite lets steel take in energy when stressed. Dual-scale TiC precipitation keeps steel hard and lets it handle impacts.

Steel should resist scraping and hitting. Wear resistance means steel fights abrasion and impact. Manganese and chromium help a lot. Manganese steel forms a tough layer when used. This layer protects the outside. The inside stays strong and flexible. Manganese steel lasts much longer than mild steel. Chromium makes steel harder and stops rust.

Labs test steel with different methods:

Dry-sand rubber-wheel test checks low-stress abrasion

Pin-on-drum test checks high-stress abrasion

Jaw crusher test checks gouging-abrasion

High-speed impeller-tumbler test checks impact–abrasion

New technology makes steel even tougher. Better alloying, casting, and heat treatment help. Surface treatments like nitriding and coatings give more protection. Simulation and modeling help engineers design steel parts that last longer.

Tip: Picking wear-resistant steel means your machines work better in tough places and need fewer repairs.

When you pick materials for heavy machines, you want them to last. Wear-resistant steel lasts much longer than regular steel. This is true in places like mines and construction sites. Regular steel wears out fast. You have to change parts more often. This means your machines stop working more and cost more money.

Here is a table that shows how each steel works in mining equipment:

Type of Steel | Service Life Comparison |

|---|---|

Wear-Resistant Steel | Lasts much longer in tough places |

Regular Steel | Wears out fast, so machines stop more often |

If you use wear-resistant steel in chutes and hoppers, they last longer. Your machines keep working well. If you use regular steel, parts wear out faster. You need to fix them more often. This stops your work and costs more money.

You also need to think about fixing your machines. Machines with wear-resistant steel need fewer repairs. They last longer before you need to check them. Here is a table that shows the difference:

Steel Type | Maintenance Intervals | Breakdown Frequency | Repair Costs |

|---|---|---|---|

Wear-Resistant Steel | Less often | Not as many | Lower |

Regular Steel | More often | More | Higher |

Tip: Wear-resistant steel costs more at first, but you save money later because you fix and change parts less.

You want your machines to work hard without breaking. Wear resistance is what makes wear-resistant steel special. This steel fights scratches, hits, and tough places better than regular steel.

Mining machines work with rocks, dirt, and hard stuff.

High carbon steel like AR 400 is best for these jobs.

Regular steel wears out faster and breaks more often.

Tests show wear-resistant steel like Hardox 600 and Hardox Extreme lose less weight in rough soil than regular steel. This means your machines stay strong longer. The steel’s hardness and ductility help it fight scratches and dents, even in hard jobs.

Wear-resistant steel breaks less under stress. It can handle hits and rubbing without failing as fast as regular steel. This means you spend less time fixing machines and more time working.

Note: Using wear-resistant steel means fewer breakdowns, longer-lasting parts, and lower repair bills. Your business works better and you save money over time.

Wear resistant steels are used in many industries. They help machines and tools last longer. These steels protect parts that get worn out fast. You can find them in mining, heavy machinery, construction, military, and farming. Each industry uses these steels for different jobs.

Here is a table that shows where wear resistant steels are used and what they do:

Industry | Specific Applications |

|---|---|

Mining | Equipment such as mine cars, crushers, and conveyor belts using AR500 or RAEX 400. |

Heavy Machinery | XAR 450 for ore transportation and maintenance in high abrasion scenarios. |

Construction | Guards and liners in building construction, transportation belts, and machinery parts. |

Military Applications | AR500 used as armor plate for vehicle protection against ballistic attacks. |

Agriculture | Used in farm shovels, crusher liners, excavators, and bulldozers for handling abrasive materials. |

You also see these steels in many types of equipment. Mining machines often use AR400 steel for liners and tools. Construction uses these steels for guards and machine parts. Truck plows and armor plating also use wear resistant steels to stay strong.

Choosing wear resistant steels saves money over time. These steels last much longer than regular steel. You do not need to change parts as often. Some companies say QT-PLUS® steels last 3 to 5 times longer than AR400 steel. This means your machines keep working and you avoid costly stops.

A foundry lost $190,128 because a cheap wear plate broke and stopped work for four days.

If you buy better wear resistant steels, you do not need to replace parts as much or pay for extra work.

You save a lot because your machines run longer and need less fixing.

Here is a table that compares the costs:

Aspect | Wear-Resistant Steel | Regular Steel |

|---|---|---|

Initial Cost | Higher | Lower |

Long-Term Savings | Significant savings due to reduced maintenance and replacement costs | Minimal savings |

Equipment Lifespan | Extended | Standard lifespan |

Tip: Even though wear resistant steels cost more at first, you save more later. Your machines work better and you spend less on repairs.

You want to make smart choices when picking steel for your machines. A value analysis helps you see the real benefits and costs. Here are the main things you should look at:

Material Costs: You pay more for wear-resistant steel because it uses special elements and needs extra steps in production.

Performance and Durability: This steel lasts much longer than regular steel. You spend less on repairs and replacements.

Manufacturing and Processing Costs: Some steel grades need special tools or heat treatments. These steps can raise the price.

Application Suitability: You need to match the steel grade to your job. Picking the right steel means your equipment works better and you avoid wasting money.

You see big savings over time with wear-resistant steel. Machines run longer and break down less. You spend less on spare parts and repairs. Your equipment stays strong, even in tough jobs like mining or construction. You get more work done because your machines do not stop as often.

You should pick wear-resistant steel when your equipment faces rough use. This steel works best in heavy-duty applications. You see the biggest benefits in places where machines scrape, hit, or carry hard materials.

Superior wear and corrosion resistance keeps your machines working in harsh conditions.

Extended equipment lifespan means you do not need to buy new parts often.

Reduced maintenance and downtime help you save money and keep your business running.

Significant cost savings come from fewer repairs and less lost time.

Uninterrupted operations let you reach maximum productivity.

If you want your machines to last and work hard, wear-resistant steel is a smart investment. You get strong returns and peace of mind knowing your equipment can handle tough jobs.

Wear-resistant steel lasts longer than regular steel. It is stronger and does not wear out as fast. This means it works better for a longer time, as you can see here:

Key Characteristics | Wear-Resistant Steel | Regular Steel |

|---|---|---|

Durability | High | Moderate |

Performance under wear | Superior | Standard |

Longevity in applications | Extended | Limited |

If you use wear-resistant steel, your machines break less. You also pay less to fix them, so you save money as time goes on.

You do not need to repair as much.

Your machines last longer.

You get better results in hard jobs.

Pick wear-resistant steel if you want strong and dependable machines.

Wear-resistant steel uses more carbon and special elements. You get higher hardness and better strength. This steel lasts longer in tough jobs. Regular steel wears out faster and needs more repairs.

Yes, you can weld wear-resistant steel. You need to use the right welding methods and filler materials. Always follow the manufacturer's guidelines. This helps you avoid cracks and keeps the steel strong.

You should use wear-resistant steel in places with lots of abrasion or impact. Mining, construction, and farming equipment all benefit. This steel works best when you need parts to last longer.

You pay more at first for wear-resistant steel. Over time, you save money. You replace parts less often and spend less on repairs. This makes it a smart choice for heavy-duty work.

Check the job and the type of wear your equipment faces. Use the steel grade that matches your needs. You can ask a supplier for advice or look at the manufacturer's charts.