English

T: +86-0731-85185770

E: enquiry@qilumetal.com

E: enquiry@qilumetal.com

No. 18 Xiangfu Middle Road,Yuhua District, Changsha City

1.2714 steel is a hot work die steel with excellent heat resistance, toughness and wear resistance, widely used in the manufacture of molds in high temperature environments. It conforms to the German DIN 17350 standard and has equivalent grades in many countries. Such as the American standard is ASTM A681 L6, the European standard is EN ISO 4957 55NiCrMoV7, and the Chinese standard is GB/T 1299 5CrNiMo.

| Availability: | |

|---|---|

| Quantity: | |

1.2714 steel is a high-grade hot-work die steel, widely recognized for its outstanding overall performance under high-temperature operating conditions. Compliant with DIN 17350 standards, it is widely recognized under equivalent grades across global standards, including ISO 55NiCrMoV7 (European), ASTM A681 L6 (American), and GB/T 1299 5CrNiMo (Chinese). This alloy is engineered to deliver superior heat resistance, exceptional toughness, and enhanced wear resistance—key properties that make it indispensable for manufacturing molds and tools operating under severe thermal and mechanical stress.

The unique composition of 1.2714 sets it apart: nickel and chromium boost toughness and hardenability, while molybdenum and vanadium enhance wear resistance and tempering stability. This balance of properties guarantees that the material retains exceptional strength and toughness during prolonged exposure to elevated temperatures, solidifying its status as the material of choice for sectors demanding dependable operation under severe thermal stress.

The chemical makeup of 1.2714 is carefully formulated to optimize performance. Key elements include:

· Carbon (0.50-0.60%): Ensures hardness and strength.

· Chromium (1.0-1.2%): Enhances corrosion resistance and hardenability.

· Nickel (1.50-1.80%): Improves toughness, critical for withstanding impact in forging processes.

· Molybdenum (0.45-0.55%) and Vanadium (0.07-0.12%): Work together to boost wear resistance and tempering stability, preventing softening at high temperatures.

Compared to similar grades, 1.2714 offers a more balanced blend of these elements, reducing the risk of cracking under thermal cycling—a common issue in lesser hot work steels.

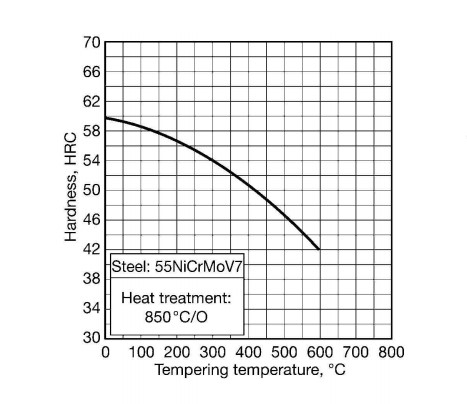

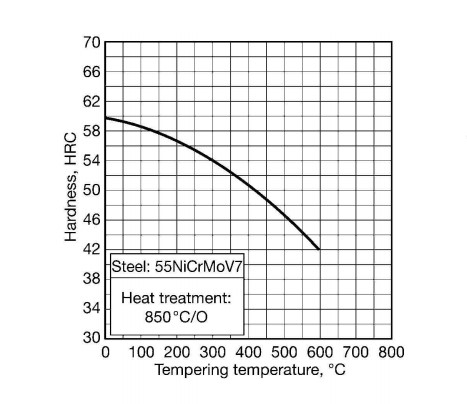

Proper heat treatment amplifies 1.2714’s capabilities:

· Annealed (+A): Maximum hardness of HB248, ensuring ease of machining.

· Cold-drawn: Maximum hardness of HB262, suitable for precision forming.

· Hardened and Tempered (+HT): Minimum hardness of HRC42, providing the strength needed for heavy-duty applications.

The steel responds well to controlled heating (840-860°C) and oil quenching, followed by tempering at 490-510°C, resulting in uniform hardness across the material.

1.2714 is produced using advanced steelmaking processes, including EF+LF+VD and EAF+LF+VD+ESR, ensuring purity and consistency. Forging is performed within a strict temperature range (initial: 1050-1100°C; final: ≥850°C) to avoid grain coarsening or cracking, followed by slow cooling to relieve internal stress.

1.2714 excels in diverse high-stress scenarios, thanks to its versatility:

· Heavy Forging Dies: Ideal for hammer and press forging of large components like automotive crankshafts and connecting rods, where repeated high-impact loads and elevated temperatures are common.

· Extrusion Dies: Used in hot extrusion of non-ferrous metals (aluminum, copper), maintaining shape stability despite prolonged contact with molten materials.

· Die Casting Dies: Suitable for zinc, aluminum, and magnesium alloy casting, resisting erosion from molten metals and thermal fatigue.

· Stamping Dies: Efficient for blanking and forming thick metal sheets, leveraging high toughness to prevent chipping.

· Shear Blades: Reliable for cutting sheet metal, with wear resistance extending tool life.

· Cold Heading Dies: Produce high-strength fasteners (bolts, nuts) by withstanding the pressure of cold forming.

· Large Injection Molds: Shapes engineering plastics (nylon, ABS) with precision, even in high-volume production.

· Blow Molds: Manufactures PET bottles and plastic containers, resisting wear from repeated contact with molten plastic.

· Machine Tool Cutters: Serves as heavy-duty cutter bodies and fixtures, enduring high cutting forces.

· Wear Parts: Rolls and guide bushings benefit from its wear resistance, reducing maintenance needs.

· Aerospace Components: Used in high-stress structural parts, where reliability under extreme conditions is non-negotiable.

Currently, 1.2714 is not stocked for domestic markets, but custom orders are available in various sizes (hot rolled bars: Φ10-Φ190mm; hot forged plates: T70-250mm) to meet specific requirements.

It complies with EN10228-3 class III or Sep 1921-84 D/D, ensuring internal integrity and reliability in critical applications.

Country | Standard | Grade |

USA | ASTM A681 | L6 |

ISO | ISO 4957 | 55NiCrMoV7 |

Germany | DIN17350 | 56NiCrMoV7/1.2714 |

China | GB/T1299 | 5CrNiMo |

Grade | C | Si | Mn | P (Max) | S (Max) | Cr | Mo | Ni | V |

L6 | 0.65-0.75 | 0.10-0.50 | 0.25-0.80 | 0.030 | 0.030 | 0.6-1.2 | 0.50Max | 1.25-2.00 | / |

55NiCrMoV7 | 0.50-0.60 | 0.10-0.40 | 0.60-0.90 | 0.030 | 0.020 | 0.8-1.2 | 0.35-0.55 | 1.50-1.80 | 0.05-0.15 |

56NiCrMoV7/1.2714 | 0.50-0.60 | 0.10-0.40 | 0.65-0.95 | 0.030 | 0.030 | 1.0-1.2 | 0.45-0.55 | 1.50-1.80 | 0.07-0.12 |

5CrNiMo | 0.50-0.60 | 0.40Max | 0.50-0.80 | 0.030 | 0.030 | 0.5-0.8 | 0.15-0.30 | 1.40-1.80 | / |

Product Type | Size Range | Length |

Hot rolled bar | Φ10-Φ190mm | 2000-5800mm |

Hot forged bar | Φ200-Φ600mm | 2000-5800mm |

Hot rolled plate | T:10-60mm; W:310-810mm | 2000-5800mm |

Hot forged plate | T:70-250mm; W:310-810mm | 2000-5800mm |

Hot Forged block | T:260-500mm; W:300-1000mm | 2000-5800mm |

1.2714 steel is a high-grade hot-work die steel, widely recognized for its outstanding overall performance under high-temperature operating conditions. Compliant with DIN 17350 standards, it is widely recognized under equivalent grades across global standards, including ISO 55NiCrMoV7 (European), ASTM A681 L6 (American), and GB/T 1299 5CrNiMo (Chinese). This alloy is engineered to deliver superior heat resistance, exceptional toughness, and enhanced wear resistance—key properties that make it indispensable for manufacturing molds and tools operating under severe thermal and mechanical stress.

The unique composition of 1.2714 sets it apart: nickel and chromium boost toughness and hardenability, while molybdenum and vanadium enhance wear resistance and tempering stability. This balance of properties guarantees that the material retains exceptional strength and toughness during prolonged exposure to elevated temperatures, solidifying its status as the material of choice for sectors demanding dependable operation under severe thermal stress.

The chemical makeup of 1.2714 is carefully formulated to optimize performance. Key elements include:

· Carbon (0.50-0.60%): Ensures hardness and strength.

· Chromium (1.0-1.2%): Enhances corrosion resistance and hardenability.

· Nickel (1.50-1.80%): Improves toughness, critical for withstanding impact in forging processes.

· Molybdenum (0.45-0.55%) and Vanadium (0.07-0.12%): Work together to boost wear resistance and tempering stability, preventing softening at high temperatures.

Compared to similar grades, 1.2714 offers a more balanced blend of these elements, reducing the risk of cracking under thermal cycling—a common issue in lesser hot work steels.

Proper heat treatment amplifies 1.2714’s capabilities:

· Annealed (+A): Maximum hardness of HB248, ensuring ease of machining.

· Cold-drawn: Maximum hardness of HB262, suitable for precision forming.

· Hardened and Tempered (+HT): Minimum hardness of HRC42, providing the strength needed for heavy-duty applications.

The steel responds well to controlled heating (840-860°C) and oil quenching, followed by tempering at 490-510°C, resulting in uniform hardness across the material.

1.2714 is produced using advanced steelmaking processes, including EF+LF+VD and EAF+LF+VD+ESR, ensuring purity and consistency. Forging is performed within a strict temperature range (initial: 1050-1100°C; final: ≥850°C) to avoid grain coarsening or cracking, followed by slow cooling to relieve internal stress.

1.2714 excels in diverse high-stress scenarios, thanks to its versatility:

· Heavy Forging Dies: Ideal for hammer and press forging of large components like automotive crankshafts and connecting rods, where repeated high-impact loads and elevated temperatures are common.

· Extrusion Dies: Used in hot extrusion of non-ferrous metals (aluminum, copper), maintaining shape stability despite prolonged contact with molten materials.

· Die Casting Dies: Suitable for zinc, aluminum, and magnesium alloy casting, resisting erosion from molten metals and thermal fatigue.

· Stamping Dies: Efficient for blanking and forming thick metal sheets, leveraging high toughness to prevent chipping.

· Shear Blades: Reliable for cutting sheet metal, with wear resistance extending tool life.

· Cold Heading Dies: Produce high-strength fasteners (bolts, nuts) by withstanding the pressure of cold forming.

· Large Injection Molds: Shapes engineering plastics (nylon, ABS) with precision, even in high-volume production.

· Blow Molds: Manufactures PET bottles and plastic containers, resisting wear from repeated contact with molten plastic.

· Machine Tool Cutters: Serves as heavy-duty cutter bodies and fixtures, enduring high cutting forces.

· Wear Parts: Rolls and guide bushings benefit from its wear resistance, reducing maintenance needs.

· Aerospace Components: Used in high-stress structural parts, where reliability under extreme conditions is non-negotiable.

Currently, 1.2714 is not stocked for domestic markets, but custom orders are available in various sizes (hot rolled bars: Φ10-Φ190mm; hot forged plates: T70-250mm) to meet specific requirements.

It complies with EN10228-3 class III or Sep 1921-84 D/D, ensuring internal integrity and reliability in critical applications.

Country | Standard | Grade |

USA | ASTM A681 | L6 |

ISO | ISO 4957 | 55NiCrMoV7 |

Germany | DIN17350 | 56NiCrMoV7/1.2714 |

China | GB/T1299 | 5CrNiMo |

Grade | C | Si | Mn | P (Max) | S (Max) | Cr | Mo | Ni | V |

L6 | 0.65-0.75 | 0.10-0.50 | 0.25-0.80 | 0.030 | 0.030 | 0.6-1.2 | 0.50Max | 1.25-2.00 | / |

55NiCrMoV7 | 0.50-0.60 | 0.10-0.40 | 0.60-0.90 | 0.030 | 0.020 | 0.8-1.2 | 0.35-0.55 | 1.50-1.80 | 0.05-0.15 |

56NiCrMoV7/1.2714 | 0.50-0.60 | 0.10-0.40 | 0.65-0.95 | 0.030 | 0.030 | 1.0-1.2 | 0.45-0.55 | 1.50-1.80 | 0.07-0.12 |

5CrNiMo | 0.50-0.60 | 0.40Max | 0.50-0.80 | 0.030 | 0.030 | 0.5-0.8 | 0.15-0.30 | 1.40-1.80 | / |

Product Type | Size Range | Length |

Hot rolled bar | Φ10-Φ190mm | 2000-5800mm |

Hot forged bar | Φ200-Φ600mm | 2000-5800mm |

Hot rolled plate | T:10-60mm; W:310-810mm | 2000-5800mm |

Hot forged plate | T:70-250mm; W:310-810mm | 2000-5800mm |

Hot Forged block | T:260-500mm; W:300-1000mm | 2000-5800mm |