English

T: +86-0731-85185770

E: enquiry@qilumetal.com

E: enquiry@qilumetal.com

No. 18 Xiangfu Middle Road,Yuhua District, Changsha City

| Availability: | |

|---|---|

| Quantity: | |

1.2714 steel is a hot work die steel with excellent heat resistance, toughness and wear resistance, widely used in the manufacture of molds in high temperature environments. It conforms to the German DIN 17350 standard and has equivalent grades in many countries. Such as the American standard is ASTM A681 L6, the European standard is EN ISO 4957 55NiCrMoV7, and the Chinese standard is GB/T 1299 5CrNiMo.

1.2714 steel contains nickel and chromium, which enhance its toughness and hardenability, while molybdenum and vanadium improve wear resistance and tempering stability. This combination of alloying elements ensures high strength and durability even under severe working conditions.

1: Steel equivalent

Country | USA | ISO | Germany | China |

Standard | ASTM A681 | ISO 4957 | DIN17350 | GB/T1299 |

Grade | L6 | 55NiCrMoV7 | 56NiCrMoV7/1.2714 | 5CrNiMo |

2: Chemical composition

Grade | C | Si | Mn | P | S | Cr | Mo | Ni | V |

L6 | 0.65-0.75 | 0.10-0.50 | 0.25-0.80 | 0.030Max | 0.030Max | 0.6-1.2 | 0.50Max | 1.25-2.00 | / |

55NiCrMoV7 | 0.50-0.60 | 0.10-0.40 | 0.60-0.90 | 0.030Max | 0.020Max | 0.8-1.2 | 0.35-0.55 | 1.50-1.80 | 0.05-0.15 |

56NiCrMoV7/1.2714 | 0.50-0.60 | 0.10-0.40 | 0.65-0.95 | 0.030Max | 0.030Max | 1.0-1.2 | 0.45-0.55 | 1.50-1.80 | 0.07-0.12 |

5CrNiMo | 0.50-0.60 | 0.40Max | 0.50-0.80 | 0.030Max | 0.030Max | 0.5-0.8 | 0.15-0.30 | 1.40-1.80 | / |

3: Surface hardness and hardenability.

Heat Treatment | Hardness |

Annealed (+A) | HB248Max |

Cold-drawn condition | HB262Max |

Hardening and Tempering (+HT) | HRC42 Min |

4: Supply size & Tolerance & Stock size

Product type | Size range | Length |

Hot rolled bar | Φ10-Φ190mm | 2000-5800mm |

Hot forged bar | Φ200-Φ600mm | 2000-5800mm |

Hot rolled plate/sheet | T:10-60mm; W:310-810mm | 2000-5800mm |

Hot forged plate | T:70-250mm; W:310-810mm | 2000-5800mm |

Hot Forged block | T: 260-500mm; W: 300-1000mm | 2000-5800mm |

Surface Finish | Turned | Milled | Grinding(Best) | Polished(Best) | Peeled(Best) | Black Forged | Black Rolled |

Tolerance | +0/+3mm | +0/+3mm | +0/+0.05mm | +0/+0.05mm | +0/+0.1mm | +0/+5mm | +0/+1mm |

Straighness | 1mm/1000mm max. | 3mm/1000mm max. | |||||

For 1.2714 steel, because we don’t use them in domestic market, so there is no stocks for that material.

5: Ultrasonic Test

EN10228-3 class III or Sep 1921-84 D/D

6:Steel making & Forging processing

1): Steel making process:

EF+LF+VD

EAF+LF+VD

EF+LF+VD+ESR

EAF+LF+VD+ESR

2): Forging processing:

1. 2714 steel should be fully pre-heated in 600-700°C before forging and then raised to forging temperature to avoid thermal stress.

Initial temperature: 1050-1100°C (avoid exceeding 1150°C to prevent overheating or grain coarsening).

Final temperature: ≥ 850°C (below 800°C may cause forging cracks).

Slow cooling, cooling in the sand or furnace.

7: Heat treatment

1): Annealed:

Heat 1.2714 steel to 790-820℃.

Cooling in the furnace (≤30°C/h) to approx. 600°C, then cooling in the air.

2): Quenching and tempering:

Preheat Temperature: 649℃

Heat 1.2714 steel to 840-860℃ in the salt bath furnace

Quench in oil

Temper steel at 490-510℃ in the furnace

Cooling in the air.

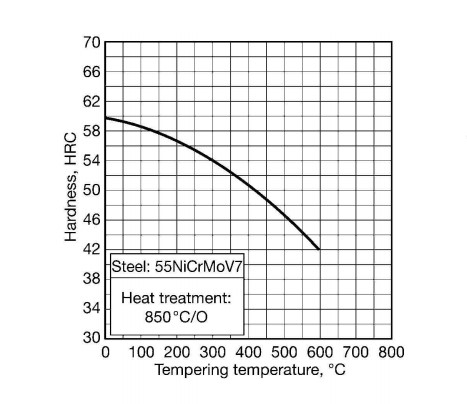

Above curve in figure is just a rough guide to the tempering behaviour of steels. When applying the curves for an estimation of the hardness which can be expected in quenched and tempered tools, it should be taken into account that the optimum heat-treatment conditions for the tools are not necessarily identical with those specified for the test pieces.

The heating time of test pieces in a salt batch shall be as give in below table:

Total heating time of test pieces in a salt bath

Nature of steel | Hardening Time min | Tempering Time min |

Cold or hot work steels | 25 +/- 1 | 60 |

High-speed steels | 3 | Minimum 2 periods of 60 each |

If the test pieces are not heated in a salt batch, the heating time must be extended accordingly, and the times for heating give above are not valid for thicker tools.

8:Application

1.2714 is a high toughness, high wear resistance nickel-chromium-molybdenum alloy tool steel, because of its excellent impact resistance and good hardenability, widely used in the following fields:

1. Hot Work Dies

1) Heavy Forging Die: for hammer forging die, press forging die (such as automotive crankshafts, connecting rods, and other large forgings)

2) Extrusion Die: used for hot extrusion molding of non-ferrous metals, such as aluminum, copper, and other non-ferrous metals

3) Die Casting Die: applicable to zinc, aluminum, magnesium alloy die casting

2. Cold Work Tools

1) Stamping Die: for thick plate blanking, forming die

2) Shear Blade: for sheet metal shearing

3) Cold Heading Die: for manufacturing bolts, nuts and other high-strength fasteners

3. Plastic Molds

1) Large-scale Injection Molds: for engineering plastics (such as nylon, ABS) molding

2) Blow Molds: for the production of PET bottles, plastic containers, etc.

4. Other Industrial Tools

1) Machine Tool Cutter : such as heavy cutting tool body, fixture

2) Wear Parts: such as rolls, guide bushings, etc.

3) Aerospace Components: used in high-stress environment of the structural components

1.2714 steel is a hot work die steel with excellent heat resistance, toughness and wear resistance, widely used in the manufacture of molds in high temperature environments. It conforms to the German DIN 17350 standard and has equivalent grades in many countries. Such as the American standard is ASTM A681 L6, the European standard is EN ISO 4957 55NiCrMoV7, and the Chinese standard is GB/T 1299 5CrNiMo.

1.2714 steel contains nickel and chromium, which enhance its toughness and hardenability, while molybdenum and vanadium improve wear resistance and tempering stability. This combination of alloying elements ensures high strength and durability even under severe working conditions.

1: Steel equivalent

Country | USA | ISO | Germany | China |

Standard | ASTM A681 | ISO 4957 | DIN17350 | GB/T1299 |

Grade | L6 | 55NiCrMoV7 | 56NiCrMoV7/1.2714 | 5CrNiMo |

2: Chemical composition

Grade | C | Si | Mn | P | S | Cr | Mo | Ni | V |

L6 | 0.65-0.75 | 0.10-0.50 | 0.25-0.80 | 0.030Max | 0.030Max | 0.6-1.2 | 0.50Max | 1.25-2.00 | / |

55NiCrMoV7 | 0.50-0.60 | 0.10-0.40 | 0.60-0.90 | 0.030Max | 0.020Max | 0.8-1.2 | 0.35-0.55 | 1.50-1.80 | 0.05-0.15 |

56NiCrMoV7/1.2714 | 0.50-0.60 | 0.10-0.40 | 0.65-0.95 | 0.030Max | 0.030Max | 1.0-1.2 | 0.45-0.55 | 1.50-1.80 | 0.07-0.12 |

5CrNiMo | 0.50-0.60 | 0.40Max | 0.50-0.80 | 0.030Max | 0.030Max | 0.5-0.8 | 0.15-0.30 | 1.40-1.80 | / |

3: Surface hardness and hardenability.

Heat Treatment | Hardness |

Annealed (+A) | HB248Max |

Cold-drawn condition | HB262Max |

Hardening and Tempering (+HT) | HRC42 Min |

4: Supply size & Tolerance & Stock size

Product type | Size range | Length |

Hot rolled bar | Φ10-Φ190mm | 2000-5800mm |

Hot forged bar | Φ200-Φ600mm | 2000-5800mm |

Hot rolled plate/sheet | T:10-60mm; W:310-810mm | 2000-5800mm |

Hot forged plate | T:70-250mm; W:310-810mm | 2000-5800mm |

Hot Forged block | T: 260-500mm; W: 300-1000mm | 2000-5800mm |

Surface Finish | Turned | Milled | Grinding(Best) | Polished(Best) | Peeled(Best) | Black Forged | Black Rolled |

Tolerance | +0/+3mm | +0/+3mm | +0/+0.05mm | +0/+0.05mm | +0/+0.1mm | +0/+5mm | +0/+1mm |

Straighness | 1mm/1000mm max. | 3mm/1000mm max. | |||||

For 1.2714 steel, because we don’t use them in domestic market, so there is no stocks for that material.

5: Ultrasonic Test

EN10228-3 class III or Sep 1921-84 D/D

6:Steel making & Forging processing

1): Steel making process:

EF+LF+VD

EAF+LF+VD

EF+LF+VD+ESR

EAF+LF+VD+ESR

2): Forging processing:

1. 2714 steel should be fully pre-heated in 600-700°C before forging and then raised to forging temperature to avoid thermal stress.

Initial temperature: 1050-1100°C (avoid exceeding 1150°C to prevent overheating or grain coarsening).

Final temperature: ≥ 850°C (below 800°C may cause forging cracks).

Slow cooling, cooling in the sand or furnace.

7: Heat treatment

1): Annealed:

Heat 1.2714 steel to 790-820℃.

Cooling in the furnace (≤30°C/h) to approx. 600°C, then cooling in the air.

2): Quenching and tempering:

Preheat Temperature: 649℃

Heat 1.2714 steel to 840-860℃ in the salt bath furnace

Quench in oil

Temper steel at 490-510℃ in the furnace

Cooling in the air.

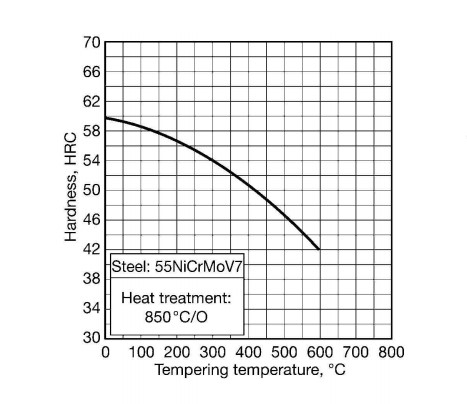

Above curve in figure is just a rough guide to the tempering behaviour of steels. When applying the curves for an estimation of the hardness which can be expected in quenched and tempered tools, it should be taken into account that the optimum heat-treatment conditions for the tools are not necessarily identical with those specified for the test pieces.

The heating time of test pieces in a salt batch shall be as give in below table:

Total heating time of test pieces in a salt bath

Nature of steel | Hardening Time min | Tempering Time min |

Cold or hot work steels | 25 +/- 1 | 60 |

High-speed steels | 3 | Minimum 2 periods of 60 each |

If the test pieces are not heated in a salt batch, the heating time must be extended accordingly, and the times for heating give above are not valid for thicker tools.

8:Application

1.2714 is a high toughness, high wear resistance nickel-chromium-molybdenum alloy tool steel, because of its excellent impact resistance and good hardenability, widely used in the following fields:

1. Hot Work Dies

1) Heavy Forging Die: for hammer forging die, press forging die (such as automotive crankshafts, connecting rods, and other large forgings)

2) Extrusion Die: used for hot extrusion molding of non-ferrous metals, such as aluminum, copper, and other non-ferrous metals

3) Die Casting Die: applicable to zinc, aluminum, magnesium alloy die casting

2. Cold Work Tools

1) Stamping Die: for thick plate blanking, forming die

2) Shear Blade: for sheet metal shearing

3) Cold Heading Die: for manufacturing bolts, nuts and other high-strength fasteners

3. Plastic Molds

1) Large-scale Injection Molds: for engineering plastics (such as nylon, ABS) molding

2) Blow Molds: for the production of PET bottles, plastic containers, etc.

4. Other Industrial Tools

1) Machine Tool Cutter : such as heavy cutting tool body, fixture

2) Wear Parts: such as rolls, guide bushings, etc.

3) Aerospace Components: used in high-stress environment of the structural components