English

T: +86-0731-85185770

E: enquiry@qilumetal.com

E: enquiry@qilumetal.com

No. 18 Xiangfu Middle Road,Yuhua District, Changsha City

| Availability: | |

|---|---|

| Quantity: | |

34CrMo4

34CrMo4 / 1.7220 is an alloy structural steel conforming to European standards EN 10083-3 and EN 10250-3. It is widely used in mechanical manufacturing, the automotive industry, energy equipment, and general engineering, often for producing medium-to-high-load components. Primary applications include gears, shafts, connecting rods, bolts, and critical structural parts in petrochemical equipment.

This steel grade is a chromium-molybdenum steel with a carbon content of approximately 0.30-0.37%. Through quenching and tempering treatment, it achieves a favorable combination of strength and toughness, along with good hardenability and fatigue resistance. 34CrMo4 maintains high strength at elevated temperatures, making it suitable for components operating within specific temperature ranges. It corresponds to multiple grades in various national standards, such as ASTM A29 4135/4137 in the United States, GB/T 3077 35CrMo in China, and JIS G4105 SCM435 in Japan.

1: Steel equivalent

Country | USA | Europe | China | Japan |

Standard | ASTM A29 | EN10250-3 | GB/T 3077 | JIS G4105 |

Grade | 4135/4137 | 34CrMo4/1.7220 | 35CrMo | SCM435 |

2: Chemical composition

Grade | C | Si | Mn | P | S | Cr | Mo |

4135 | 0.33-0.38 | 0.15-0.35 | 0.70-0.90 | 0.035Max | 0.040Max | 0.80-1.10 | 0.15-0.25 |

34CrMo4/1.7220 | 0.30-0.37 | 0.40Max | 0.60-0.90 | 0.035Max | 0.035Max | 0.90-1.20 | 0.15-0.30 |

35CrMo | 0.32-0.40 | 0.17-0.37 | 0.40-0.70 | 0.030Max | 0.030Max | 0.80-1.10 | 0.15-0.25 |

SCM435 | 0.33-0.38 | 0.15-0.35 | 0.60-0.85 | 0.030Max | 0.030Max | 0.90-1.20 | 0.15-0.30 |

3: Mechanical properties .

Mechanical properties for 34CrMo4 quenching and tempering alloy steel according to EN10083-3.

Size range | Tensile strength | Yield strength | Alongation | Area of reduction | Impact value At RT/J |

d≤16 t≤8 | 1000-1200Mpa | 800Mpa Min | 11% Min | 45% Min | / |

16<d≤40 8<t≤20 | 900-1100Mpa | 650Mpa Min | 12% Min | 50%Min | 40J Min |

40<d≤100 20<t≤60 | 800-950Mpa | 550Mpa Min | 14% Min | 55%Min | 45J Min |

100<d≤160 60<t≤100 | 750-900Mpa | 500Mpa Min | 15% Min | 55%Min | 45J Min |

160<d≤250 100<t≤160 | 700-850Mpa | 450Mpa Min | 15% Min | 60%Min | 45J Min |

Sampling and preparation of test pieces for 34CrMo4 quenching and tempering steel.

1): According to EN10083-1, all samples shall be taken at a distance of 12.5mm below the heat treated surface

2): As stipulated in the contract between buyer and seller.

Mechanical properties for 34CrMo4 open die forgings steel according to EN10250-3

Size range | Tensile strength | Yield strength | Alongation | Impact value at RT/J | ||

L | Tr | L | Tr | |||

d≤70 | 800Mpa Min | 550Mpa Min | 14% Min | 45J Min | ||

70<d≤160 | 700Mpa Min | 450Mpa Min | 15% Min | 10% Min | 40J Min | 22J Min |

160<d≤330 | 650Mpa Min | 410Mpa Min | 16% Min | 12% Min | 33J Min | 17J Min |

Remark: L= Longitudinal Tr = Transverse

Sampling and preparation of test pieces for steel forging.

1: According to EN10250-1, all samples shall be taken at a distance of 4/T below the heat treated surface (with a minimum of 20mm and a maximum of 80mm), and t/2 from the end (where t is the equivalent thickness of the thickness of the ruling section of the forging at the time of heat treatment.

2: As stipulated in the contract between buyer and seller.

4: Surface hardness and hardenability.

Heat Treatment | Hardness |

| Treated to improve shearability (+S) | HB255Max |

Soft annealed (+A) | HB223Max |

Quenched and tempred (+QT) | HRC28-32(Common Range) |

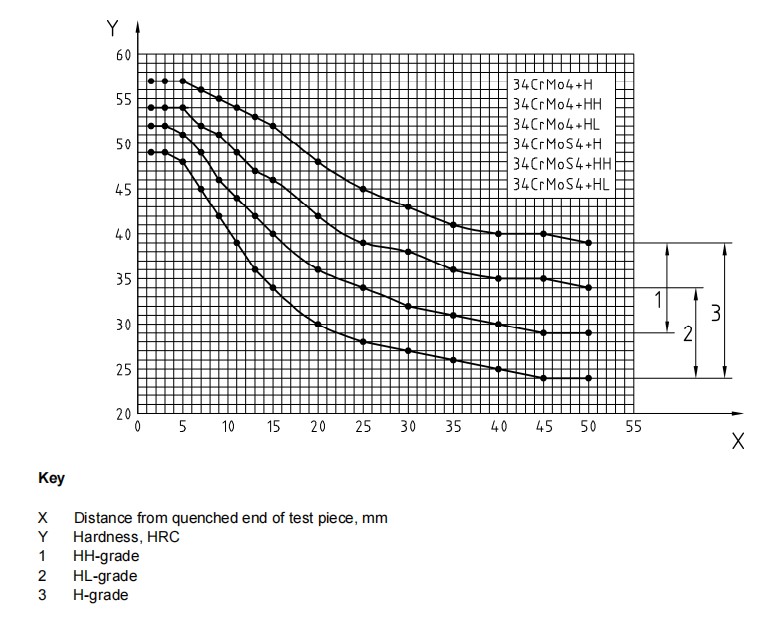

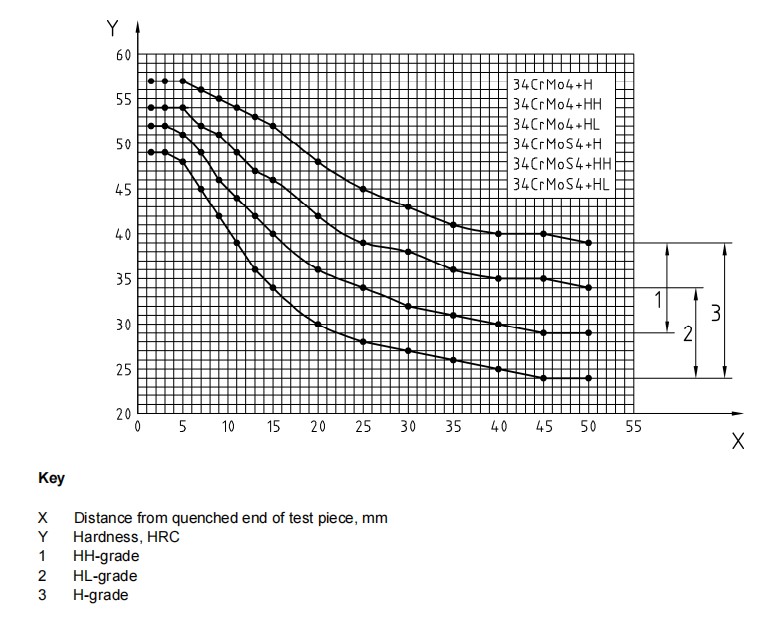

Where the steel is ordered by using the symbols for normal (+H) or restricted (+HL, +HH) hardenability requirements, the hardenability values should apply below:

Distance in mm from quenched end | ||||||||||||||||

Distance | 1.5 | 3 | 5 | 7 | 9 | 11 | 13 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | |

Hardness In HRC + H | max | 57 | 57 | 57 | 56 | 55 | 54 | 53 | 52 | 48 | 45 | 43 | 41 | 40 | 40 | 39 |

min | 49 | 49 | 48 | 45 | 42 | 39 | 36 | 34 | 30 | 28 | 27 | 26 | 25 | 24 | 24 | |

Hardness In HRC + HH | max | 57 | 57 | 57 | 56 | 55 | 54 | 53 | 52 | 48 | 45 | 43 | 41 | 40 | 40 | 39 |

min | 52 | 52 | 51 | 49 | 46 | 44 | 42 | 40 | 36 | 34 | 32 | 31 | 30 | 29 | 29 | |

Hardness In HRC + HL | max | 54 | 54 | 54 | 52 | 51 | 49 | 47 | 46 | 42 | 39 | 38 | 36 | 35 | 35 | 34 |

min | 49 | 49 | 48 | 45 | 42 | 39 | 36 | 34 | 30 | 28 | 27 | 26 | 25 | 24 | 24 | |

Scatter bands for the Rockwell - C hardness in the end quench hardenability test.

5: Supply size & Tolerance & Stock size

Product type | Size range | Length |

Hot rolled bar | Φ16-Φ300mm | 6000-9000mm |

Hot forged bar | Φ140-Φ800mm | 3000-5800mm |

Hot rolled plate/sheet | T:12-120mm; W:1500-2500mm | 2000-5800mm |

Hot Forged block | T: 80-800mm; W: 100-2500mm | 2000-5800mm |

Surface Finish | Turned | Milled | Grinding(Best) | Polished(Best) | Peeled(Best) | Black Forged | Black Rolled |

Tolerance | +0/+3mm | +0/+3mm | +0/+0.05mm | +0/+0.05mm | +0/+0.1mm | +0/+5mm | +0/+1mm |

Straighness | 1mm/1000mm max. | 3mm/1000mm max. | |||||

Qilu steel stock hot rolled bar and forged bars more than ten thousands tons every month, below our our stock size.

1): Stock diameter for hot rolled bar

16 | 18 | 19 | 20 | 22 | 25 | 28 | 30 | 32 | 35 | 38 | 40 | 42 | 45 | 48 |

50 | 55 | 60 | 65 | 70 | 75 | 80 | 85 | 90 | 95 | 100 | 105 | 110 | 115 | 120 |

125 | 130 | 140 | 150 | 160 | 170 | 180 | 190 | 200 | 210 | 220 |

Since the stocks change everyday, if you want to know our stock available information, please contact our salesman.

6:Forging processing

Put the 34CrMo4 ingot into the furnace and heat to 1150-1200℃

Cooling in the sand after forged

7: Heat treatment

Soft annealed:

Heat 34CrMo4 steel to 850-880℃ in the furnace

Heat the steel above the Ac3 line (achieving full austenitization), hold at this temperature for a sufficient duration, then cool slowly with the furnace (cooling rate approximately 10-30°C/hour)

Normalized:

Heat 34CrMo4 steel to 860-870℃ in the furnace

Soak at this temperature in the furnace

Cooling in the air

Quenching and tempering:

Heat 34CrMo4 steel to 830-890℃ in the furnace

Soak at this temperature in the furnace

Quench in water or oil

Temper steel at 540-680℃ in the furnace

Take out of 34CrMo4 steel from furnace and cool in the air.

Remark: The conditions given above are for guidance, at the temperatures at the lower end of the range are generally applicable to hardening in water and those at the upper end for hardening in oil.

8: Weldability

34CrMo4 steel has acceptable but limited weldability. This is primarily due to its carbon content and alloy composition, which increase the risk of hardening and cracking during welding. When the carbon content exceeds 0.25%, weldability begins to deteriorate. The carbon content of 34CrMo4 typically falls within the range of 0.30% to 0.37%, placing it in a category that requires strict control of welding procedures.

9:Application

34CrMo4 steel, with its excellent strength, toughness, hardenability, and high-temperature performance, is widely used across multiple industrial sectors for manufacturing critical components subjected to moderate to high loads, impact, and alternating stresses. Its primary application areas and typical components are as follows:

1. General Machinery and Heavy Industry

Gears and Drive Shafts: Medium to large gears, transmission gear shafts, drive shafts, etc.

Shaft Components: Machine tool spindles, pump shafts, fan shafts, turbine rotor shafts (non-high-temperature sections), etc.

Connecting Elements: High-strength bolts, connecting rods, pins, etc.

2. Automotive Industry

Engine Components: Connecting rods, camshafts, crankshafts (select models)

Chassis Components: Critical safety parts including steering knuckles, half-shafts, differential gears

3. Energy and Petrochemical Equipment

Oil Drilling Equipment: Drill pipe joints, sucker rods, valve bodies

Pressure Vessels and Piping: Fasteners, flanges, and pipe fittings for medium-temperature/medium-pressure applications

Power Plant Equipment: Non-high-temperature rotor components and fasteners in turbines and generators

4. Molds and Tools

Plastic molds: Large injection mold frames requiring high strength and wear resistance

Tooling fixtures: Fixtures and tool support components in heavy machinery demanding high rigidity and wear resistance

34CrMo4 / 1.7220 is an alloy structural steel conforming to European standards EN 10083-3 and EN 10250-3. It is widely used in mechanical manufacturing, the automotive industry, energy equipment, and general engineering, often for producing medium-to-high-load components. Primary applications include gears, shafts, connecting rods, bolts, and critical structural parts in petrochemical equipment.

This steel grade is a chromium-molybdenum steel with a carbon content of approximately 0.30-0.37%. Through quenching and tempering treatment, it achieves a favorable combination of strength and toughness, along with good hardenability and fatigue resistance. 34CrMo4 maintains high strength at elevated temperatures, making it suitable for components operating within specific temperature ranges. It corresponds to multiple grades in various national standards, such as ASTM A29 4135/4137 in the United States, GB/T 3077 35CrMo in China, and JIS G4105 SCM435 in Japan.

1: Steel equivalent

Country | USA | Europe | China | Japan |

Standard | ASTM A29 | EN10250-3 | GB/T 3077 | JIS G4105 |

Grade | 4135/4137 | 34CrMo4/1.7220 | 35CrMo | SCM435 |

2: Chemical composition

Grade | C | Si | Mn | P | S | Cr | Mo |

4135 | 0.33-0.38 | 0.15-0.35 | 0.70-0.90 | 0.035Max | 0.040Max | 0.80-1.10 | 0.15-0.25 |

34CrMo4/1.7220 | 0.30-0.37 | 0.40Max | 0.60-0.90 | 0.035Max | 0.035Max | 0.90-1.20 | 0.15-0.30 |

35CrMo | 0.32-0.40 | 0.17-0.37 | 0.40-0.70 | 0.030Max | 0.030Max | 0.80-1.10 | 0.15-0.25 |

SCM435 | 0.33-0.38 | 0.15-0.35 | 0.60-0.85 | 0.030Max | 0.030Max | 0.90-1.20 | 0.15-0.30 |

3: Mechanical properties .

Mechanical properties for 34CrMo4 quenching and tempering alloy steel according to EN10083-3.

Size range | Tensile strength | Yield strength | Alongation | Area of reduction | Impact value At RT/J |

d≤16 t≤8 | 1000-1200Mpa | 800Mpa Min | 11% Min | 45% Min | / |

16<d≤40 8<t≤20 | 900-1100Mpa | 650Mpa Min | 12% Min | 50%Min | 40J Min |

40<d≤100 20<t≤60 | 800-950Mpa | 550Mpa Min | 14% Min | 55%Min | 45J Min |

100<d≤160 60<t≤100 | 750-900Mpa | 500Mpa Min | 15% Min | 55%Min | 45J Min |

160<d≤250 100<t≤160 | 700-850Mpa | 450Mpa Min | 15% Min | 60%Min | 45J Min |

Sampling and preparation of test pieces for 34CrMo4 quenching and tempering steel.

1): According to EN10083-1, all samples shall be taken at a distance of 12.5mm below the heat treated surface

2): As stipulated in the contract between buyer and seller.

Mechanical properties for 34CrMo4 open die forgings steel according to EN10250-3

Size range | Tensile strength | Yield strength | Alongation | Impact value at RT/J | ||

L | Tr | L | Tr | |||

d≤70 | 800Mpa Min | 550Mpa Min | 14% Min | 45J Min | ||

70<d≤160 | 700Mpa Min | 450Mpa Min | 15% Min | 10% Min | 40J Min | 22J Min |

160<d≤330 | 650Mpa Min | 410Mpa Min | 16% Min | 12% Min | 33J Min | 17J Min |

Remark: L= Longitudinal Tr = Transverse

Sampling and preparation of test pieces for steel forging.

1: According to EN10250-1, all samples shall be taken at a distance of 4/T below the heat treated surface (with a minimum of 20mm and a maximum of 80mm), and t/2 from the end (where t is the equivalent thickness of the thickness of the ruling section of the forging at the time of heat treatment.

2: As stipulated in the contract between buyer and seller.

4: Surface hardness and hardenability.

Heat Treatment | Hardness |

| Treated to improve shearability (+S) | HB255Max |

Soft annealed (+A) | HB223Max |

Quenched and tempred (+QT) | HRC28-32(Common Range) |

Where the steel is ordered by using the symbols for normal (+H) or restricted (+HL, +HH) hardenability requirements, the hardenability values should apply below:

Distance in mm from quenched end | ||||||||||||||||

Distance | 1.5 | 3 | 5 | 7 | 9 | 11 | 13 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | |

Hardness In HRC + H | max | 57 | 57 | 57 | 56 | 55 | 54 | 53 | 52 | 48 | 45 | 43 | 41 | 40 | 40 | 39 |

min | 49 | 49 | 48 | 45 | 42 | 39 | 36 | 34 | 30 | 28 | 27 | 26 | 25 | 24 | 24 | |

Hardness In HRC + HH | max | 57 | 57 | 57 | 56 | 55 | 54 | 53 | 52 | 48 | 45 | 43 | 41 | 40 | 40 | 39 |

min | 52 | 52 | 51 | 49 | 46 | 44 | 42 | 40 | 36 | 34 | 32 | 31 | 30 | 29 | 29 | |

Hardness In HRC + HL | max | 54 | 54 | 54 | 52 | 51 | 49 | 47 | 46 | 42 | 39 | 38 | 36 | 35 | 35 | 34 |

min | 49 | 49 | 48 | 45 | 42 | 39 | 36 | 34 | 30 | 28 | 27 | 26 | 25 | 24 | 24 | |

Scatter bands for the Rockwell - C hardness in the end quench hardenability test.

5: Supply size & Tolerance & Stock size

Product type | Size range | Length |

Hot rolled bar | Φ16-Φ300mm | 6000-9000mm |

Hot forged bar | Φ140-Φ800mm | 3000-5800mm |

Hot rolled plate/sheet | T:12-120mm; W:1500-2500mm | 2000-5800mm |

Hot Forged block | T: 80-800mm; W: 100-2500mm | 2000-5800mm |

Surface Finish | Turned | Milled | Grinding(Best) | Polished(Best) | Peeled(Best) | Black Forged | Black Rolled |

Tolerance | +0/+3mm | +0/+3mm | +0/+0.05mm | +0/+0.05mm | +0/+0.1mm | +0/+5mm | +0/+1mm |

Straighness | 1mm/1000mm max. | 3mm/1000mm max. | |||||

Qilu steel stock hot rolled bar and forged bars more than ten thousands tons every month, below our our stock size.

1): Stock diameter for hot rolled bar

16 | 18 | 19 | 20 | 22 | 25 | 28 | 30 | 32 | 35 | 38 | 40 | 42 | 45 | 48 |

50 | 55 | 60 | 65 | 70 | 75 | 80 | 85 | 90 | 95 | 100 | 105 | 110 | 115 | 120 |

125 | 130 | 140 | 150 | 160 | 170 | 180 | 190 | 200 | 210 | 220 |

Since the stocks change everyday, if you want to know our stock available information, please contact our salesman.

6:Forging processing

Put the 34CrMo4 ingot into the furnace and heat to 1150-1200℃

Cooling in the sand after forged

7: Heat treatment

Soft annealed:

Heat 34CrMo4 steel to 850-880℃ in the furnace

Heat the steel above the Ac3 line (achieving full austenitization), hold at this temperature for a sufficient duration, then cool slowly with the furnace (cooling rate approximately 10-30°C/hour)

Normalized:

Heat 34CrMo4 steel to 860-870℃ in the furnace

Soak at this temperature in the furnace

Cooling in the air

Quenching and tempering:

Heat 34CrMo4 steel to 830-890℃ in the furnace

Soak at this temperature in the furnace

Quench in water or oil

Temper steel at 540-680℃ in the furnace

Take out of 34CrMo4 steel from furnace and cool in the air.

Remark: The conditions given above are for guidance, at the temperatures at the lower end of the range are generally applicable to hardening in water and those at the upper end for hardening in oil.

8: Weldability

34CrMo4 steel has acceptable but limited weldability. This is primarily due to its carbon content and alloy composition, which increase the risk of hardening and cracking during welding. When the carbon content exceeds 0.25%, weldability begins to deteriorate. The carbon content of 34CrMo4 typically falls within the range of 0.30% to 0.37%, placing it in a category that requires strict control of welding procedures.

9:Application

34CrMo4 steel, with its excellent strength, toughness, hardenability, and high-temperature performance, is widely used across multiple industrial sectors for manufacturing critical components subjected to moderate to high loads, impact, and alternating stresses. Its primary application areas and typical components are as follows:

1. General Machinery and Heavy Industry

Gears and Drive Shafts: Medium to large gears, transmission gear shafts, drive shafts, etc.

Shaft Components: Machine tool spindles, pump shafts, fan shafts, turbine rotor shafts (non-high-temperature sections), etc.

Connecting Elements: High-strength bolts, connecting rods, pins, etc.

2. Automotive Industry

Engine Components: Connecting rods, camshafts, crankshafts (select models)

Chassis Components: Critical safety parts including steering knuckles, half-shafts, differential gears

3. Energy and Petrochemical Equipment

Oil Drilling Equipment: Drill pipe joints, sucker rods, valve bodies

Pressure Vessels and Piping: Fasteners, flanges, and pipe fittings for medium-temperature/medium-pressure applications

Power Plant Equipment: Non-high-temperature rotor components and fasteners in turbines and generators

4. Molds and Tools

Plastic molds: Large injection mold frames requiring high strength and wear resistance

Tooling fixtures: Fixtures and tool support components in heavy machinery demanding high rigidity and wear resistance